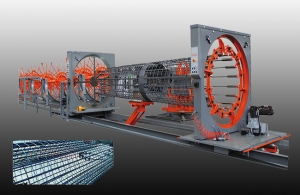

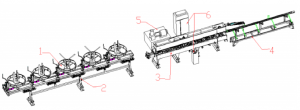

how steel rebar shear line working?

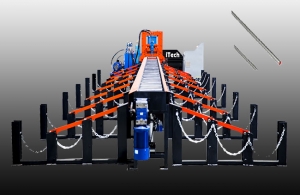

Steel rebar shear line, also called cnc rebar shear line,rebar shearing line,automatic rebar shear line.

This steel rebar processing equipment is from Europea design.with its the reality of China market, rebar shear line widely use in rebar cut&bend.

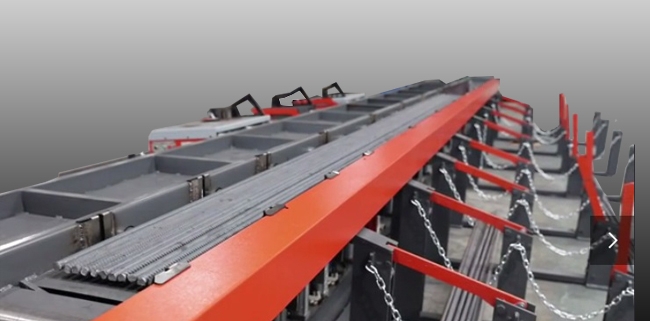

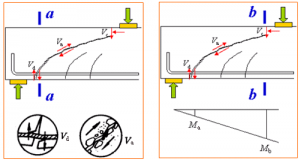

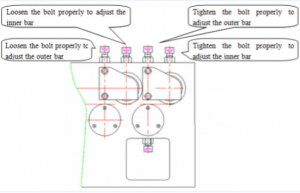

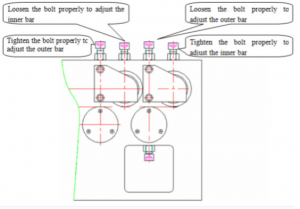

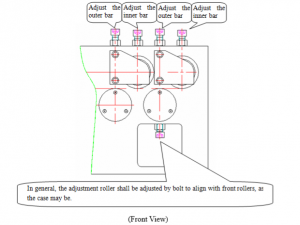

It use a servo motor to adjust the distance between the cutting blade and the positioning baffle. The encoder is used for measurement, with a high accuracy of sizing, up to ±2mm. it make steel bar cut to length. The CNC steel bar shearing production line adopts the hydraulic shearing method, which is small in size, large in shearing force, and high output. Compared with the mechanical punching and shearing methods, it is low noise, long service life and stable operation of the equipment. at the same time, CNC rebar cutting line adopts oil cylinder to press the material, the pressure is large, the steel bar will not rotate when cutting, and the steel bar will be evenly cut. The hydraulic system adopts a new type of subwoofer plunger oil pump, and the oil tank has undergone special treatment, which greatly reduces the problem of stuck valve clogging.

The hydraulic cylinder adopts imported seals, which greatly increases the service life. Innovative design, compared with other manufacturers’ hydraulic shears of the same ton, the shearing capacity is increased by 1/3, which greatly improves the work efficiency; the new hydraulic system design, such as the hydraulic system of other manufacturers’ hydraulic shears to meet the technical requirements when cutting φ25 steel bars The working pressure must reach 25Mpa. The company’s hydraulic system only needs 15Mpa, which can meet the technical requirements. In comparison, itech hydraulic steel bar cutting line system greatly increases the service life.

Pneumatic system design concept for the steel bar cutting line, the main pipeline adopts stainless steel pipe transmission, reducing the compressed air loss; the solenoid valve is installed under the corresponding control cylinder, the response speed is fast.

The number and specifications of the steel bar can be set Etc.

The technical parameters of the automatic steel rebar shear line

produced by ITECH:

- Shearing steel bar diameter range: Φ12~40mm;

- Shearing length range: 1~12m;

- Shearing accuracy: ±2mm;

- Shearing frequency: 20 times /Min

- Conveying speed: 1.92m/s

- Number of operators: 1

- Equipment power: 25.5KW

- Equipment dimensions: 28m×3.3m×2.5m

- Electric control system: 380V, 50~60HZ

- Hydraulic system: system pressure 31.5Mpa, hydraulic station motor 18.5KW

- Shearing energy meter (third-grade steel, 57kg/mm2)

Itech is professional supplier in the production of CNC steel rebar shear line. How much is the CNC steel bar cutting line?Welcome to inquiry!

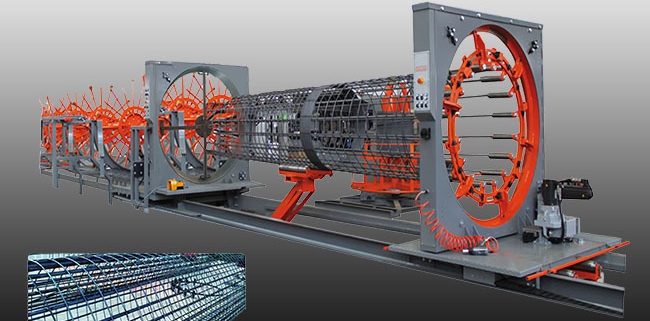

Itech as one professional steel wire/bar processing machinery China supplier,stirrup bending machine, rebar bending machine,cage making machine,,steel wire straightener, wire mesh welding machine,rebar shear line,sawing&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.

rebar shear and bending line itech

rebar shear and bending line itech stirrup mkaing machine

stirrup mkaing machine

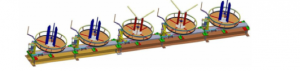

steel pile cage welding machine

steel pile cage welding machine

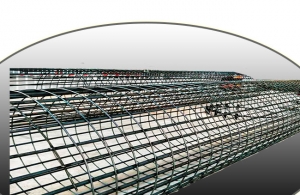

foundation cage

foundation cage

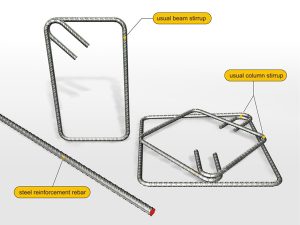

rebar stirrup bender

rebar stirrup bender

Lattice girder welding machine

Lattice girder welding machine anti twist stirrup bender

anti twist stirrup bender

rebar stirrup bender

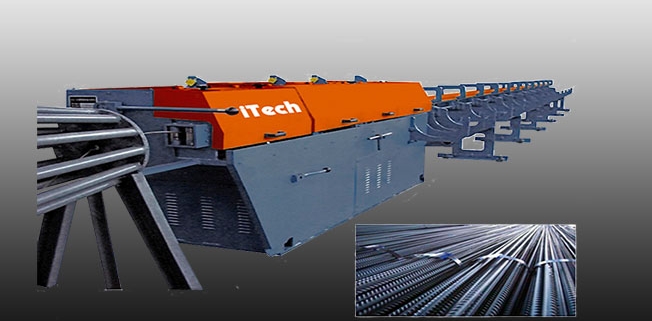

rebar stirrup bender  straightening and cutting machine

straightening and cutting machine

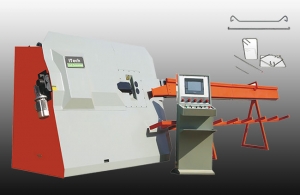

BENDING MACHINE

BENDING MACHINE