China national holidays is coming itech rebar machine supplier will have days off but service no stop

China national holidays is coming itech rebar machine supplier will have days off but service no stop

China national holidays is coming itech rebar machine supplier will have days off but service no stop.As autumn descends on China, the air is filled with excitement and anticipation for one of the country’s most important events: National Day. This week-long holiday, celebrated annually from October 1 to 7, marks the founding of the People’s Republic of China in 1949. On this festival, people across the country come together to reflect on its long history, commemorate its achievements, and embrace the spirit of New China. of unity and patriotism.

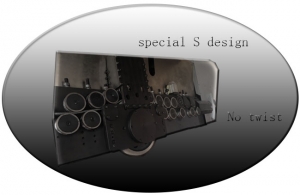

Itech Best selling CNC high quality automatic stirrup bending machine / CNC stirrup bender machine widely use in reinforcement steel wire bar cut and bend factory. Itech as professional reinforcing steel machine supplier. Itech have a series of steel rebar bender machine,like CNC 16mm Stirrup Bending machine,CNC 20mm stirrup bar bending machine , 14mm stirrup wire bending machine and bar shape machine ,automatic rebar pile cage welding machine,cnc automatic pile cage making machine and many kinds of rebar machine. To solve the gap on the stirrups ,Itech stirrup bending machine adopt advanced anti twist feeding system to avoid twist of steel, make stirrup more quick and standard.Shape and bend stirrups effortlessly with our cutting-edge bending machine.

National Day is not just a day off; This is a grand celebration showcasing China’s diverse culture and traditions. Cities across the country are decorated with vibrant decorations and the streets are alive with people preparing for various festivities. From the bustling metropolises of Beijing and Shanghai to the tranquil landscapes of the countryside, this holiday season is a time for locals and tourists to immerse themselves in the beauty of Chinese culture.

various cultural events are held throughout the week. Traditional performances such as dragon dances, lion dances, and folk concerts will be held in public squares and parks. These activities not only entertained attendees but also introduced them to China’s rich cultural heritage. Families often gather together to enjoy these performances, fostering a sense of community and togetherness.

China’s National Day is a vibrant celebration that embodies the national spirit. This is a time to reflect, celebrate and connect. Whether through parades, cultural performances or family gatherings, this festival offers a unique way to see the heart of China. As the country continues to evolve, National Day remains a cherished tradition that reminds everyone of the strength and resilience of the Chinese people. So whether you’re a local or a visitor, embracing the festivities of this extraordinary holiday is an experience not to be missed.

China national holidays is coming itech rebar machine supplier will have days off but service no stop. Itech as professional steel wire/bar processing machinery China supplier. We will have dayoff from 1th-7th. But our service will not stop. stirrup bending machine price , steel rebar bending machine,foundation pile cage making machine,,steel wire straightener,wire straightening and cutting machine, wire mesh welding machine,rebar shear line,rebar sawing&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.

Concrete Show South East Asia - itech rebar cut and bend machine China manufacture & supplier

Concrete Show South East Asia - itech rebar cut and bend machine China manufacture & supplier

rebar shear and bend line

rebar shear and bend line  rebar stirrup bender

rebar stirrup bender

foundation cage

foundation cage