Stirrup rebar bender / stirrup bending machine common faults and solve solution

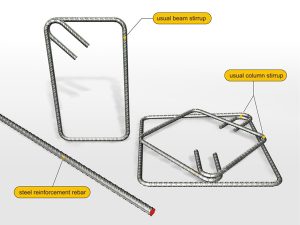

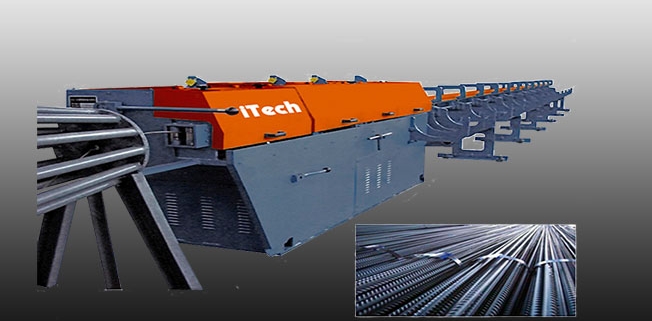

Stirrup rebar bender, also called stirrup bending machine, tmt ring making machine.it is wildly use in precast factory, concrete projects, cut&bend factory. People met some problem when use it, steel stirrup bender machine faults and solve solution can help when bending stirrups.

“Fault code: 009

electricity failure

due to power fail

Reason:

- Drive firmware error”

“Failure code: 010

FPGA firmware download program failed

FPGA Programming Failed

Reason:

- Drive firmware error”

“Fault code: 011

The firmware version and FPGA hardware modification are not compatible

due to incompatible FPGA

Reason:

- Drive firmware error”

“Fault code: 012

Invalid parameter configuration

Reason:

- Parameter configuration error”

“Failure code: 013

IGBT control main power bridge failure

Reason:

- Drive power module failure”

“Failure code: 014

IGBT control second power bridge failure

Bridge 2

Reason:

- Drive power module failure”

“Fault code: 015

Flash sector is damaged

Flash SysLog The flash sector is damaged

Reason:

- The internal storage unit of the drive is damaged”

“Fault code: 016

Safe torque off function execution

Reason:

- Firmware error”

“Fault code: 017

The instantaneous value of the actual current of the drive is higher than the allowable value of the drive

Reason:

- Servo motor wiring is abnormal

- The software detects the power transistor overcurrent

- The encoder is abnormal”

“Fault code: 018

The actual instantaneous value of the second power bridge of the driver is higher than the allowable value of the driver

Reason:

- Servo motor wiring is abnormal

- The software detects the power transistor overcurrent

- The encoder is abnormal”

“Fault code: 019

Overvoltage fault

Reason:

- The main circuit DC voltage is abnormally high”

“Fault code: 020

DC bus voltage is too low

Reason:

- The main circuit DC voltage is insufficient”

“Fault code: 021

The difference between the absolute channel and the incremental channel of the encoder exceeds the allowable value

Main Encoder Abs/Rel Track Check Failure

Reason:

- Encoder parameter setting error”

“Fault code: 022

The power supply voltage of the encoder is out of the valid range

Encoder Supply Voltage Failure

Reason:

- Encoder parameter setting error

Itech as one professional steel wire/bar processing machinery China supplier,stirrup rebar bending machine, rebar bending machine,cage making machine,,steel wire straightener, wire mesh welding machine,rebar shear line,sawing&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.check website http://www.itechbendingmachine.com

rebar stirrup bender

rebar stirrup bender

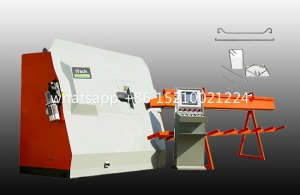

Lattice girder welding machine

Lattice girder welding machine anti twist stirrup bender

anti twist stirrup bender

rebar stirrup bender

rebar stirrup bender  straightening and cutting machine

straightening and cutting machine