Drilling Company Uses Pile rebar Cage welding Machine

Drilling Company Uses Pile Cage Machine: Revolutionizing Construction Efficiency

In the field of construction, innovation and efficiency are key factors that determine the success and profitability of a project. The drilling company industry is no exception, as companies constantly seek new technologies and machinery to maximize productivity and streamline processes. One such technology that has revolutionized the way drilling companies operate is the pile cage machine,the rebar cage welding machine also are important equipment in steel Cut&bend factory.

Itech Best selling CNC high quality automatic stirrup bending machine / CNC stirrup bender machine widely use in reinforcement steel wire bar cut and bend factory. Itech as professional reinforcing steel machine supplier. Itech have a series of steel rebar bender machine,like CNC 16mm Stirrup Bending machine,CNC 20mm stirrup bar bending machine , 14mm stirrup wire bending machine and bar shape machine and many kinds of rebar machine. To solve the gap on the stirrups ,Itech stirrup bending machine adopt advanced anti twist feeding system to avoid twist of steel, make stirrup more quick and standard.

The pile cage machine, also known as a rebar cage machine, is a cutting-edge piece of equipment designed to automate the construction of reinforcement cages used in pile foundations. These cages are essential in providing stability and strength to the structure being built. Traditionally, creating these cages was a time-consuming and labor-intensive process, requiring the manual bending of reinforcement bars and securing them with wire ties. However, with the pile cage machine, this process is now performed much faster and with significantly less human intervention.

Drilling companies that have adopted the pile cage machine have experienced a remarkable increase in productivity and efficiency. The machine’s automated processes eliminate the need for manual bending and securing of bars, reducing the time required to construct reinforcement cages by up to 80%. This allows drilling companies to complete projects in a fraction of the time it would have taken using traditional methods, resulting in significant cost savings.

Moreover, the pile cage machine offers unparalleled accuracy and consistency in the construction of reinforcement cages. By utilizing computer-aided design (CAD) technology and precise measurements, the machine ensures that every cage produced meets the exact specifications required by the project. This reduces the risk of errors or inconsistencies commonly associated with manual construction methods, ultimately enhancing the structural integrity of the final product.

In addition to boosting efficiency and accuracy, the pile cage machine also improves worker safety. The machine’s automated operation eliminates the need for workers to perform physically demanding tasks such as bending heavy reinforcement bars, significantly reducing the risk of injuries. This not only protects the well-being of the workforce but also minimizes the liability and associated costs for drilling companies.

The use of the pile cage machine has had a profound impact on the drilling industry, enabling companies to take on larger projects and increase their competitiveness in the market. With faster construction times, enhanced precision, and improved safety standards, drilling companies can now deliver exceptional results to their clients while optimizing their resources.

As the demand for infrastructure development continues to grow, drilling companies must embrace innovative technologies like the pile cage machine to stay ahead of the competition. With its ability to revolutionize productivity, accuracy, and safety, this machine is undoubtedly a game-changer in the construction industry.

In summary, the introduction of the pile cage machine has transformed the way drilling companies operate. With its automated processes, it has significantly increased productivity, ensured accuracy, improved worker safety, and ultimately propelled the growth and success of drilling companies. As technology continues to advance, the construction industry can look forward to more groundbreaking innovations that will revolutionize the way projects are carried out, shaping the future of infrastructure development.

Itech is professional steel wire/bar processing machinery China supplier,stirrup bending machine price , steel rebar bending machine,foundation pile cage making machine,,steel wire straightener,wire straightening and cutting machine, wire mesh welding machine,rebar shear line,rebar sawing&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.

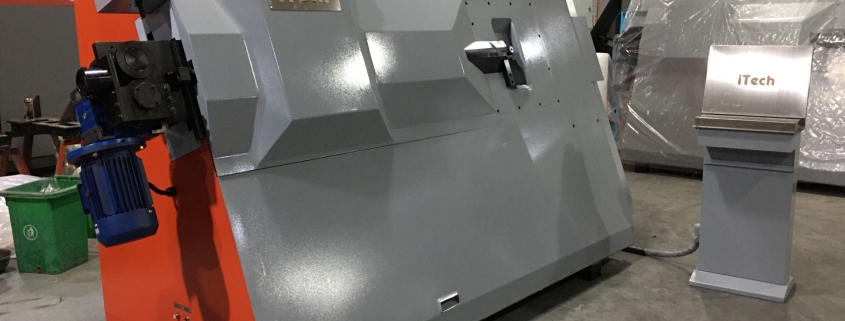

cage welding machine

cage welding machine steel reinforcement stirrup bending machine

steel reinforcement stirrup bending machine

stirrups bender

stirrups bender