What’s Full automatic reinforcing steel wire mesh welding machine?

Full automatic reinforcing steel wire mesh welding machine,also called reinforcement steel wire mesh making machine, wire mesh machine.it is steel wire mesh processing equipment in cut&bend factory.Itech automatic wire mesh weding machine price is not such high as italy schnell ,schlatter price.itech wire mesh welding machine widely use in cut and bend factory, precast factory, building materials store.We have tnt ring making machine,rebar shear line, stirrup rebar bender, rebar cutting machine ,automatic pile cage welding machine,steel wire mesh welding machine…..cut and bend machine.

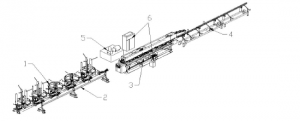

Wire mesh welding machine have many unit.like

1、line wire pay off;2、line wire detection;3、line wire

straightening;4、line wire traction & storage;5、 welder;6、line wire feeding(include: wire pay off, straightening,cutting,blanking);7、mesh shear&cut;

8、stacking;9、electric system;10、cooling system; 11、pneumatic system

1 、Line Wire Pay-off Mechanism

The pay-off mechanism includes the base, the discharge trays, the brake mechanism, etc. Bearings are installed between the base and the turntable, so that the turntable can be flexibly rotated when it is working, and the brake mechanism can adjust the flexibility of the turntable when there is no material discharged.In such case, the coil will not automatically spread. The single frame can bear 1200KG.

2 、LineWire Detecting

Line wire detecting includes guild frame, material shortage detection, etc. When the line wire coil is used up, the machine will stop and alarm automatically, and the computer operation screen will show the lack of material.

3 、Straightening Mechanism

The straightening mechanism includes base,frame,straightening rollers and guiding mechanism. The straightening roller includes a horizontal straightening roller and a vertical straightening roller, half of which are installed on the slider.It needs to be adjusted to a suitable position so thatit can make the straightening.

4、 Traction Storage Mechanism

The traction storage mechanism mainly includes:traction pressure wheel,storage rack,the detecting device etc. The wires passing through the straightening mechanism are provided with traction force by the pressure wheel traction

mechanism and sent to the storage rack. Detecting device is designed on the upper and lower sides of the storage rack to ensure that there are line wire to be provided to the host for welding purpose.

5、Stepping Mechanism

The stepping mechanism mainly includes stepper traction components, precise

straightening elements and conduit etc.. Stepping traction is realized by clamping the wire through two sets of upper and lower pressing rollers, and the roller

is driven by the servo motor to pull the wires and control the spacing of the cross wire. The precise straightening elements straighten the wires by adjusting two sets of straightening rollers and it assures the quality of the mesh. The function of the conduitis to make sure straightness of wires.

6、 Welder & Feeding Stepper

It is composed of frame, air reservoir, pressurized cylinder, lifting device, welding transformer, cross wire terminal alignment part,cross wire detection

device,cross wire adsorption device etc. . It is key part of the whole line.The line wires enter the welding area through guiding elements, and the cross wire is

adsorbed to the space between the upper and lower electrodes by the magnet after falling into the welding area through the action of the blanking mechanism.when the cross wire detecting device detects the wires in place,the alignment valve acts which will make the length of cross wires terminals

alignment. Then the pressurized cylinder is activated,the welding transformer discharges and welds according to the set current and time. After the welding is completed, the pressurized cylinder returns

7、Cross Wire Blanking Mechanism

It is composed of wire pay off mechanism,straightening device,gear box,cutter, blanking etc. Servo motor will pull out the wires from wire pay off mechanism and send them to straightening mechanism for straightening. After straightened, the wires will be cut by cutter and delivered to electrodes for welding

8、Mesh Shear&Cut Mechanism

This part is used for shearing the mesh according to the product length.The mesh spacing and shearing position can be set through control panel according to the specifications.

9、Mesh Stacking

It includes unloading rack,conveyance roller etc. The stacked meshes will be sent to packing area for winding and transportation

10, Electrical Control System

This system includes high voltage distribution cabinet and low voltage distribution cabinet one for each,one operation control bench for controlling the pneumatic circuit of welding and production line.

11, Water Cooling System

Cooling water system are composed by 4 parts: transformer water cooling,upper-down water

cooling,control box cooling.It assures the normal working of device and avoid any damage.

12, Pneumatic System

It is equipped with air filter device for purifying the compressed air and has a muffler.

The air reservoir is adopted to separate the impurity like dust,water and oil from the air and Pneumatic electromagnetic valve are used in this device.

Itech insist provide best service for all customers.As high quality rebar machine supplier China,we want to provide customers more quick and more reliable service.

ITECH stirrup making machine is stable. Automatic stirrup bender, With advanced feeding system,also called anti-twist system. It is feature as shape rebar feeding,servo motor control rebar bending, rebar cutting.It use servo motor as power, extra encoder make accouter, so make tolerance more small and high precision. It can process 6-12mm single wire, 6-10mm double wire, one hour can up 1600 pieces production capacity.

Itech as one professional steel wire/bar processing machinery China supplier,stirrup rebar bending machine, rebar bending machine,cage making machine,,steel wire straightener,truss girder welding machine,lattice girder machine, steel wire mesh welding machine,rebar shear line,sawing&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.check website http://www.itechbendingmachine.com

rebar bender

rebar bender  wire straightening and cutting machine

wire straightening and cutting machine

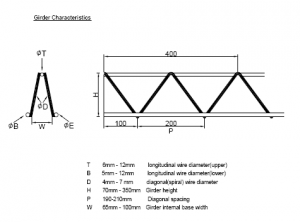

truss gieder welding machine truss girder

truss gieder welding machine truss girder

wire mesh machine

wire mesh machine