itech reinforcement stirrup bending machine supplier merry chrismas

itech reinforcement stirrup bending machine supplier merry chrismas

Itech reinforcement steel rebar stirrup bending machine supplier wish you merry christmas.The holiday season is a special time of year when people come together to celebrate and spread joy. One of the most anticipated holidays during this time is Christmas. Christmas is a time for giving, sharing, and creating lasting memories with loved ones. From decorating the house with festive lights and ornaments to gathering around the table for a delicious meal, there are countless traditions that make Christmas so special.

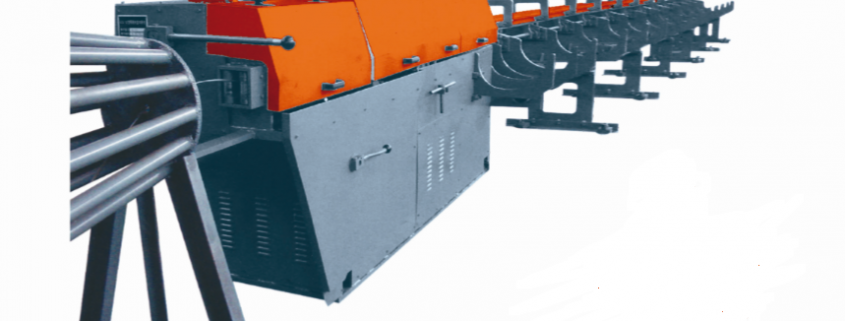

Itech Best selling CNC high quality automatic stirrup bending machine / CNC stirrup bender machine widely use in reinforcement steel wire bar cut and bend factory. Itech as professional reinforcing steel machine supplier. Itech have a series of steel rebar bender machine,like CNC 16mm Stirrup Bending machine,CNC 20mm stirrup bar bending machine , 14mm stirrup wire bending machine and bar shape machine ,automatic rebar pile cage welding machine and many kinds of rebar machine. To solve the gap on the stirrups ,Itech stirrup bending machine adopt advanced anti twist feeding system to avoid twist of steel, make stirrup more quick and standard.Shape and bend stirrups effortlessly with our cutting-edge bending machine.

The holiday season is a special time of year when people come together to celebrate and spread joy. One of the most anticipated holidays during this time is Christmas. Christmas is a time for giving, sharing, and creating lasting memories with loved ones. From decorating the house with festive lights and ornaments to gathering around the table for a delicious meal, there are countless traditions that make Christmas so special.

One of the most beloved aspects of Christmas is the tradition of exchanging gifts. The excitement of giving and receiving presents creates a magical atmosphere that fills everyone with joy. Whether it’s finding the perfect gift for a loved one or unwrapping a thoughtful present, the spirit of giving brings people closer together during the holiday season.

In addition to gift-giving, another cherished tradition of Christmas is decorating the Christmas tree. The sight of a beautifully adorned tree with sparkling lights and colorful ornaments is a symbol of the holiday season. Families gather to decorate the tree, sharing stories and laughter as they hang each ornament in its special place. The Christmas tree serves as a focal point for the holiday festivities, bringing warmth and cheer to the home.

itech reinforcement stirrup bending machine supplier merry chrismas. Another highlight of the Christmas season is the delicious food and treats that are enjoyed during this time. From traditional dishes such as roast turkey and stuffing to festive desserts like gingerbread cookies and fruitcake, there is no shortage of delectable delights to indulge in. Christmas is a time to savor the flavors of the season and gather around the table with loved ones to share a memorable meal.

Christmas is a time of celebration, giving, and spreading joy to others. Whether it’s through the exchange of gifts, the decorating of the Christmas tree, or the indulgence in delicious holiday treats, there are countless traditions that make Christmas a special time of year. And above all, it’s an opportunity to embrace the spirit of giving, kindness, and togetherness that defines the true meaning of Christmas.

Itech is professional steel wire/bar processing machinery China supplier,stirrup bending machine price , steel rebar bending machine,foundation pile cage making machine,,steel wire straightener,wire straightening and cutting machine, wire mesh welding machine,rebar shear line,rebar sawing&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.itech reinforcement stirrup bending machine supplier merry chrismas.

high speed straightening machine

high speed straightening machine