Reinforcement steel rebar pile cage machine rebar cage making machine cage welding machine

Reinforcement steel rebar pile cage machine rebar cage making machine cage welding machine

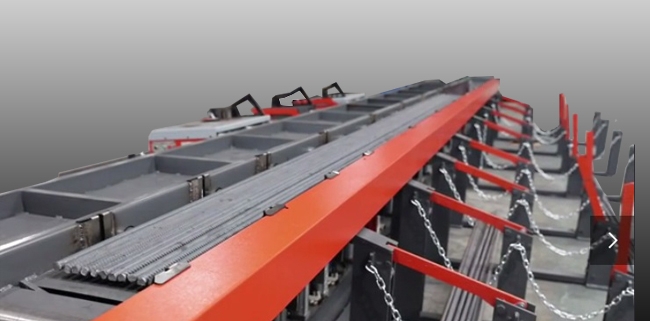

Reinforcement steel rebar pile cage machine plays a vital role in the manufacture of slab cages, which are used to strengthen concrete elements such as columns, beams and slabs. Capabilities of rebar foundation cage making machine are most time use in the construction process,foundation,bridge.For the construction industry, efficiency and precision are key factors in ensuring structural quality and durability. One of the essential tools in the construction of reinforced concrete structures is the steel cage welding machine.

Itech Best selling CNC high quality automatic stirrup bending machine / CNC stirrup bender machine widely use in reinforcement steel wire bar cut and bend factory. Itech as professional reinforcing steel machine supplier. Itech have a series of steel rebar bender machine,like CNC 16mm Stirrup Bending machine,CNC 20mm stirrup bar bending machine , 14mm stirrup wire bending machine and bar shape machine ,automatic rebar pile cage welding machine,cnc automatic pile cage making machine and many kinds of rebar machine. To solve the gap on the stirrups ,Itech stirrup bending machine adopt advanced anti twist feeding system to avoid twist of steel, make stirrup more quick and standard.Shape and bend stirrups effortlessly with our cutting-edge bending machine.

Reinforcing steel rebar cage welding machines are designed to automate the manufacturing process of rebar cages, which are essentially steel frames that are assembled and welded together to form a rigid structure. This structure provides the necessary reinforcement to the concrete elements, ensuring their strength and elasticity. The machine works by feeding steel bars from coils, straightening and cutting them to the required length, then assembling and welding the bars according to the specified design and dimensions to form the curtain cage.

The function of the cage welding machine is multi-faceted and has various advantages during the construction process. First, it significantly reduces the manual labor required to manufacture laminate cages, thereby increasing productivity and efficiency. The machine is capable of producing slab cages with high precision and consistency, ensuring uniform reinforcement of concrete elements. This level of accuracy is critical to meeting the structural requirements and standards of building projects.

In addition, the use of pilling pile cage welding machines enhances the safety of the manufacturing process. By automating the handling and welding of rebar, the risk of injuries from manual labor can be minimized. This is especially important for large construction projects that require a large number of curtain cages. The machine also helps create a cleaner, more organized work environment because it eliminates the mess and waste typically associated with manual manufacturing methods.

In addition to its efficiency and safety advantages, plate cage welding machines offer versatility in plate cage manufacturing. It can be adapted to a variety of designs and configurations, allowing the production of customized panel cages to meet the specific requirements of different construction projects. This adaptability is essential to meet the diverse structural needs of modern architectural practice.

The importance of a cage welder goes beyond its function in the manufacturing process. It also helps improve the overall quality and durability of reinforced concrete structures. By ensuring precise assembly and welding of steel bars, the machine helps maintain the integrity of the steel cage, thereby improving the structural performance of concrete elements. This is critical to ensuring the longevity and safety of buildings and infrastructure.

In summary, the functionality of a panel cage welding machine is an integral part of the construction industry, providing efficiency, precision, safety and versatility in the panel cage manufacturing process. Its role in automating steel assembly and welding processes helps improve the overall quality and durability of reinforced concrete structures. As construction practices continue to evolve, the use of innovative equipment, such as cage welders, remains vital to meeting the needs of modern construction projects.

Itech is professional steel wire/bar processing machinery China supplier,stirrup bending machine price , steel rebar bending machine,foundation pile cage making machine,,steel wire straightener,wire straightening and cutting machine, wire mesh welding machine,rebar shear line,rebar sawing&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.

cage welding machine

cage welding machine rebar shear and bending line itech

rebar shear and bending line itech rebar double bending machine

rebar double bending machine steel reinforcement stirrup bending machine

steel reinforcement stirrup bending machine