Steel wire straightening machine (wheel type and spinner type ) difference

Steel wire straightening machine, also called straightener, straightening and cutting machine. The steel bar straightening and cutting machine is a kind of straightening machine, and it is also an important steel wire/bar processing equipment like stirrup rebar bending machine. Mainly used for straightening steel wire, cutting steel wire below 14mm, the cutting length can be set according to customer requirements, spinner straightener and wheel straightener are fast, with small errors, and large output. They are widely used in construction sites and welding Mesh factory, precast factory, cut&bend factory.https://itechbendingmachine.com/products/straightening-and-cutting-machine/

What’s difference about the wire straightener machine ? Straightening method is the biggest difference.

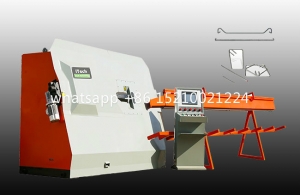

1) Regarding the high-speed spinner type straightening machine, this type of straightener machine achieves the purpose of straightening by placing a straightening module in the spinner, and the spinner rotates at a high speed. The straightening module is a wearing part. There are two types of straightening modules. One is Tungsten carbide dyes, and the other is cast-iron dyes with high hardness. The service life of the tungsten carbide type straightening module is three times longer than that of the alloy cast iron module. (10 tungsten carbide straightening modules, if it is hot-rolled rebar, it can straighten 200 tons of steel wire. If it is cold-rolled steel bars or smooth round steel wire, it can straighten 600 tons. https://www.facebook.com/itech.bendingmachine/videos/1402625523463669

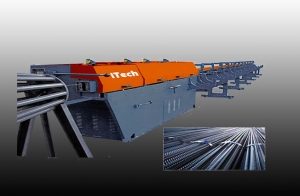

2) Regarding the wheel straightening machine, the straightening of the wheel straightener machine is composed of two sets of multi-wheel straightening and straightening systems, which are equipped with mobile memory test in the part, and the building steel wire of different diameters are removed and replaced, and the straightening wheels will automatically Adjust downwards or upwards to quickly straighten building steel wire and reduce building steel straightening time. The whole process is fully automated. Multi-wheel groups simultaneously pull building steel wire. The working pressure of the wheels and building steel wire is reduced, and the driving force is small. Thereby reducing energy consumption and building steel loss.

Itech as one professional steel wire/bar processing machinery China supplier,stirrup bending machine, rebar bending machine,cage making machine,wire mesh welding machine,rebar shear line,saw&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.

rebar stirrup bender

rebar stirrup bender