China itech Automatic Stirrup Bending Machine wish all Dad happy father day

China itech Automatic Stirrup Bending Machine wish all Dad happy father day

China itech Automatic Stirrup Bending Machine wish all Dad happy father day. Father’s Day is a time to honor the hard work, dedication, and unwavering support dads provide. For the countless fathers in construction, steel fixing, and concrete reinforcement, that often means long hours, physically demanding tasks, and a constant focus on getting the job done right and safely. This year, consider celebrating the practical, forward-thinking dads with a solution that truly impacts their daily grind: the revolutionary Automatic Stirrup Bending Machine.

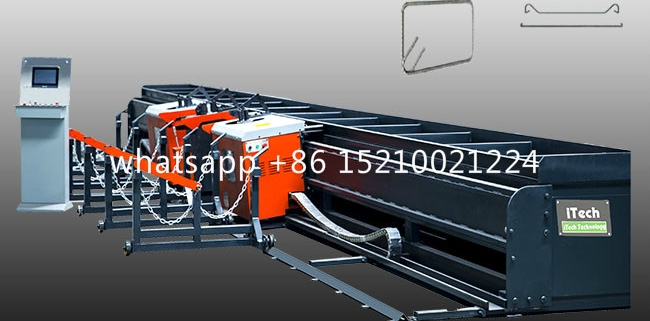

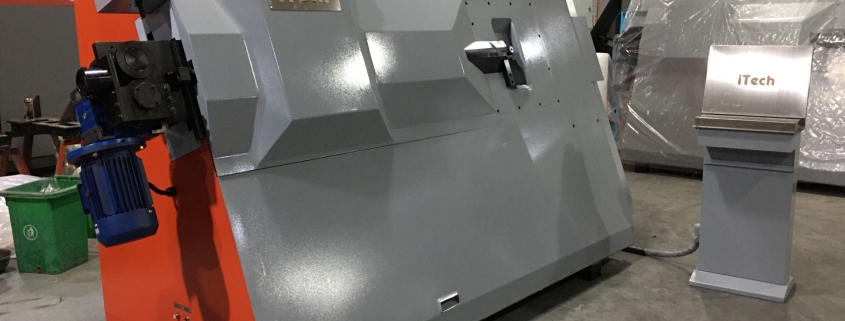

Itech Best selling CNC high quality automatic stirrup bending machine / CNC stirrup bender machine widely use in reinforcement steel wire bar cut and bend factory. Itech as professional reinforcing steel machine supplier. Itech have a series of steel rebar bender machine,like CNC 16mm Stirrup Bending machine,CNC 20mm stirrup bar bending machine , 14mm stirrup wire bending machine and bar shape machine ,automatic rebar pile cage welding machine,cnc automatic pile cage making machine and many kinds of rebar machine. To solve the gap on the stirrups ,Itech stirrup bending machine adopt advanced anti twist feeding system to avoid twist of steel, make stirrup more quick and standard.Shape and bend stirrups effortlessly with our cutting-edge bending machine.

Gone are the days of back-breaking manual bending. Traditional methods of shaping rebar stirrups – the essential loops reinforcing concrete structures – are notoriously slow, inconsistent, and physically taxing. They demand repetitive motions, significant strength, and carry a high risk of strain or repetitive stress injuries. For the dad who builds our world, this manual process eats into valuable time he could spend with family and increases on-site risks.

Stirrup bender machine Enter the game-changer: The Automatic Stirrup Bending Machine. This sophisticated piece of construction automation is designed specifically to transform stirrup production:

Improve cut and bend factory Speed & Efficiency: Feed in straight rebar, input dimensions (length, width, bend angles, hook styles) via an intuitive control panel, and watch as the machine precisely bends perfect stirrups in seconds. Output skyrockets compared to manual labor.

Pinpoint Accuracy & Consistency: Every single stirrup is identical. This ensures structural integrity, simplifies assembly on-site, and eliminates costly waste from errors – a huge relief for detail-oriented dads and project managers alike.

Ergonomic Relief & Enhanced Safety: Removes the need for strenuous manual bending, drastically reducing fatigue and the risk of musculoskeletal injuries. Operators simply load rebar and unload finished stirrups, promoting a safer, more comfortable work environment. That’s peace of mind any father deserves.

Automatic rebar bender reduced Labor Costs & Skill Dependency: While skilled workers are always valuable, automatic stirrup benders significantly reduce the intense manual labor required. They allow existing crews to focus on higher-value tasks like placement and tying, optimizing manpower.

Versatility: Modern machines handle a wide range of rebar diameters (typically from 4mm to 16mm or more) and can produce complex shapes (rectangular, square, circular, even hairpin stirrups) with various hook configurations effortlessly.

Why is an Automatic Stirrup Bending Machine the Ultimate Father’s Day Thought for the Construction Pro Dad?

It’s more than just a machine; it’s an investment in his well-being, productivity, and future. It directly addresses the core challenges of his trade:

Gift of Time: Slashes stirrup production time, meaning earlier finishes and more precious hours with family.

Gift of Safety: Significantly reduces physical strain and injury risk, ensuring he comes home healthy.

Gift of Pride: Delivers professional-grade, consistent results, boosting job satisfaction and reputation.

Gift of Efficiency: Increases project throughput and profitability, whether he owns a business or leads a crew.

This Father’s Day, move beyond the traditional gifts. Honor the dads who build our foundations with technology that honors their craft and their health. An automatic stirrup bending machine isn’t just a powerful rebar processing tool; it’s a tangible way to say “Thank you” for all the hard work, while giving him the invaluable gifts of time, safety, and efficiency. It’s the future of rebar fabrication, delivered today. For the dad committed to building stronger, safer structures, give him the machine that helps build a better work-life balance.

Itech is professional steel wire/bar processing machinery China supplier,stirrup bending machine price , steel rebar bending machine,foundation pile cage making machine,,steel wire straightener,wire straightening and cutting machine, wire mesh welding machine,rebar shear line,rebar sawing&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.

rebar double bender

rebar double bender

steel reinforcement stirrup bending machine

steel reinforcement stirrup bending machine

concrete show south america

concrete show south america

stirrups bender

stirrups bender