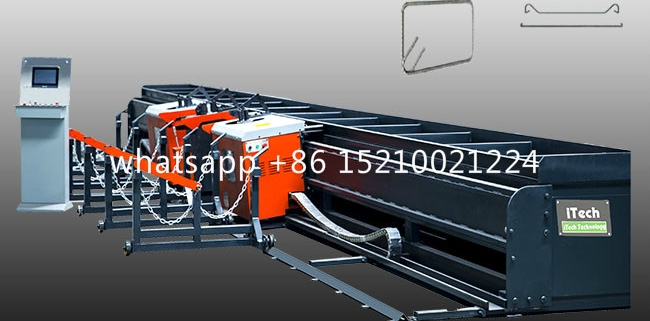

Reinforcement steel rebar double bender machine in steel fabricate cut and bend factory

Reinforcement steel rebar double bender machine in steel fabricate cut and bend factory

Reinforcement steel rebar double bender machine is used rebar bending mahine in steel fabricate cut and bend factory. Automatic double bender is mainly for steel straight bar.Rebar is an important component of construction projects, providing strength and stability to concrete structures. However, bending steel bars to the required specifications can be a time-consuming and labor-intensive task. This is where double bending machines in cutting and bending plants come into play., With itceh high speed straightening machines, you can increase productivity and efficiency while maintaining the highest quality standards.

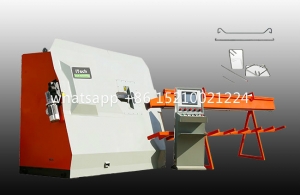

Itech Best selling CNC high quality automatic stirrup bending machine / CNC stirrup bender machine widely use in reinforcement steel wire bar cut and bend factory. Itech as professional reinforcing steel machine supplier. Itech have a series of steel rebar bender machine,like CNC 16mm Stirrup Bending machine,CNC 20mm stirrup bar bending machine , 14mm stirrup wire bending machine and bar shape machine ,automatic rebar pile cage welding machine,cnc automatic pile cage making machine and many kinds of rebar machine. To solve the gap on the stirrups ,Itech stirrup bending machine adopt advanced anti twist feeding system to avoid twist of steel, make stirrup more quick and standard.Shape and bend stirrups effortlessly with our cutting-edge bending machine.

automatic double bending machine is a specialized machine designed to bend steel bars into the desired angle and shape accurately and efficiently. By using automatic double bending machine in your cutting and bending shop, you can significantly reduce the time and effort required to bend steel bars, thereby increasing productivity and saving costs.

One of the main advantages of using cnc double bender in a cutting and bending shop is the precision and accuracy it provides. The machine is equipped with advanced technology that ensures every bend is made to precise specifications, eliminating the need for manual adjustments and reducing the risk of errors. This kind of accuracy is especially important in construction projects, as even small deviations from the required steel bar specifications can cause structural problems.

In addition to precision, double bending machines in cutting and bending plants offer versatility. The machine is capable of bending steel bars into a variety of shapes and angles, allowing the bars to be customized to meet the specific needs of each construction project. This flexibility helps minimize waste and reduce the need for additional steel reinforcement materials, resulting in cost savings for construction companies.

In addition, the use of rebar bending machines in cutting and bending plants also improves the overall safety of the steel bending process. By automating the bending process, the machine reduces the need to manually handle heavy steel material, reducing the risk of workplace injuries and improving worker safety.

The use of double rebar bender in cutting and bending plants can bring significant benefits to construction companies, including increased productivity, cost savings, precision, versatility and improved safety.

In conclusion, if you are in the construction industry and are looking for a more efficient and reliable way to bend steel bars, consider using bar bending machine in your cutting and bending shop. This specialized machine offers many benefits that can help streamline the steel bending process and increase the overall efficiency of your construction project. Invest in a double press brake today and experience the difference it can make in your cutting and bending shop.

Itech is professional steel wire/bar processing machinery China supplier,stirrup bending machine price , steel rebar bending machine,foundation pile cage making machine,,steel wire straightener,wire straightening and cutting machine, wire mesh welding machine,rebar shear line,rebar sawing&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.

rebar double bender

rebar double bender  wire straightening and cutting machine

wire straightening and cutting machine

rebar pile cage machine

rebar pile cage machine

happy new year 2024

happy new year 2024