How to maintain full automatic stirrup rebar bending machine in cut and bend factories

How to maintain full automatic stirrup rebar bending machine in cut and bend factories

Master Your Machine: Essential Maintenance for Fully Automatic Stirrup Benders.

In the high-stakes world of steel cut and bend factories, your fully automatic stirrup bender is the powerhouse driving rebar cage production. Unplanned downtime isn’t just inconvenient; it’s a direct hit to your bottom line. Proactive maintenance is the non-negotiable key to keeping this precision machine bending flawlessly, day in and day out. Ignore it, and you risk costly repairs, scrapped material, and missed deadlines. Master it, and you ensure peak performance, extended lifespan, and maximum return on investment.

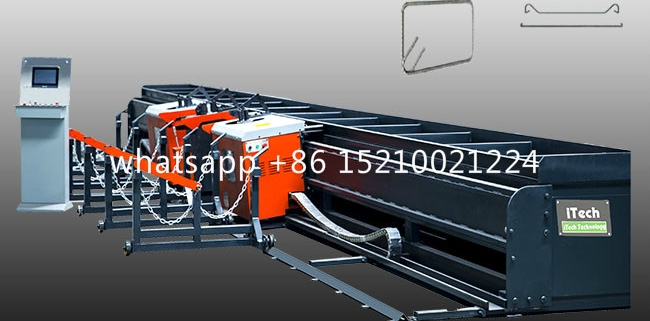

Itech Best selling CNC high quality automatic stirrup bending machine / CNC stirrup bender machine widely use in reinforcement steel wire bar cut and bend factory. Itech as professional reinforcing steel machine supplier. Itech have a series of steel rebar bender machine,like CNC 16mm Stirrup Bending machine,CNC 20mm stirrup bar bending machine , 14mm stirrup wire bending machine and bar shape machine ,automatic rebar pile cage welding machine,cnc automatic pile cage making machine and many kinds of rebar machine. To solve the gap on the stirrups ,Itech stirrup bending machine adopt advanced anti twist feeding system to avoid twist of steel, make stirrup more quick and standard.Shape and bend stirrups effortlessly with our cutting-edge bending machine.

Why Proactive Maintenance is Your Profit Protector:

Minimized Downtime: Preventative checks catch small issues before they become catastrophic failures, keeping your production line humming.

Consistent Quality: Well-maintained benders deliver precise bends, meeting stringent tolerances every time, reducing rework and waste.

Extended Equipment Life: Regular care significantly delays wear and tear, protecting your substantial capital investment.

Reduced Operating Costs: Avoiding major repairs and minimizing scrapped rebar directly boosts your profitability.

Enhanced Safety: A well-maintained machine is a safer machine, reducing risks associated with malfunctions.

Your Essential Stirrup Bender Maintenance Checklist:

Don’t wait for the screech of metal or the halt of production. Implement these critical maintenance routines:

Daily Discipline (Operator Focused):

Visual Inspection: Before startup, check for obvious damage, leaks (oil, hydraulic fluid), loose bolts, and foreign objects near bending heads, feed mechanisms, and sensors.

Lubrication Points: Apply lubricant (as per manufacturer specs – often grease or light oil) to designated chains, guides, sliding surfaces, and pivot points. Never over-lubricate.

Cleanliness is Key: Remove accumulated steel dust, dirt, and grime from bending heads, mandrels, feed rollers, and sensor eyes using brushes, rags, or approved compressed air (take care near electronics). Debris causes jams and wear.

Sensor Check: Verify optical/positioning sensors are clean and unobstructed for accurate bending and feeding.

Listen & Feel: Pay attention to unusual noises (grinding, knocking) or vibrations during operation – report immediately.

Weekly Watchfulness (Technician Led):

Detailed Lubrication: Replenish central lubrication systems if fitted. Check grease levels in gearboxes and bearings.

Bolt & Fastener Check: Systematically tighten critical bolts on bending heads, frames, feed systems, and clamps according to torque specifications. Vibration loosens them!

Hydraulic/Pneumatic Systems: Check fluid levels (hydraulic oil, compressor oil). Inspect hoses and fittings for leaks, cracks, or wear. Ensure air filters/dryers are functioning.

Wear Part Inspection: Examine bending pins, mandrels, shear blades (if integrated), and feed rollers for excessive wear, chipping, or deformation. Document findings.

Alignment Verification: Quickly check critical alignments (e.g., feed path to bending head).

Monthly Mastery (Comprehensive Technician Check):

Thorough Wear Assessment: Remove and closely inspect key wear components identified weekly. Measure against tolerances and replace proactively.

Hydraulic Fluid Check: Monitor fluid condition (color, clarity, smell) and top up/filter/replace as per schedule. Contaminated fluid damages pumps and valves.

Electrical Connections: Inspect terminal blocks, connectors, and wiring harnesses for tightness, corrosion, or damage (power off/locked out!).

Drive System Check: Inspect belts, chains, sprockets, and gears for tension, wear, and alignment. Adjust or replace as needed.

Software & Backups: Ensure control software is up-to-date. Back up critical machine parameters and programs.

Annual Expertise (Manufacturer/Deep Dive):

Professional Calibration: Schedule a comprehensive calibration of bending angles, feed lengths, and sensor accuracy by qualified technicians, often the OEM.

Major Component Inspection: Deep inspection of motors, gearboxes, hydraulic pumps, valves, and structural integrity.

Fluid Replacement: Full replacement of hydraulic fluid and filters.

Bearing Replacement: Proactive replacement of major bearings nearing end-of-life.

Critical Components Demanding Extra Attention:

Bending Heads & Mandrels: Subject to immense force. Inspect pins, dies, and mandrels constantly for cracks, wear, or deformation. Replace before failure causes poor bends or jams.

Feed Rollers & Guides: Ensure smooth, consistent rebar feeding. Check for flat spots, grooves, and alignment. Worn rollers cause feeding errors.

Sensors (Positioning, Presence): Vital for automation. Keep lenses clean and check alignment regularly. Faulty sensors lead to misfeeds or incorrect bends.

Hydraulic System: The machine’s muscle. Monitor fluid level, temperature, and cleanliness religiously. Address leaks immediately.

Invest in Knowledge: Train Your Team!

Empower operators and maintenance technicians with specific training on your machine model. Understanding proper operation, daily care routines, and early fault recognition is paramount. Keep detailed maintenance logs – they reveal patterns and predict failures.

Conclusion: Maintenance = Productivity

How to maintain full automatic stirrup rebar bending machine in cut and bend factories.Treating your fully automatic stirrup bender as a partner, not just a tool, pays massive dividends. By implementing a rigorous, scheduled maintenance program tailored to daily, weekly, monthly, and annual needs, you transform from fighting fires to achieving smooth, predictable, and highly profitable production. Protect your investment, ensure consistent quality, and keep your steel bending factory operating at its competitive peak. Start mastering your maintenance today!

Itech is professional steel wire/bar processing machinery China supplier,stirrup bending machine price , steel rebar bending machine,foundation pile cage making machine,,steel wire straightener,wire straightening and cutting machine, wire mesh welding machine,rebar shear line,rebar sawing&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.

rebar bender

rebar bender  stirrups bender

stirrups bender

wire mesh

wire mesh

steel reinforcement stirrup bending machine

steel reinforcement stirrup bending machine pile cage machine

pile cage machine

rebar double bender

rebar double bender

rebar shear line

rebar shear line