steel bar bending machine and cage machine in the first bridge of world

steel bar bending machine and cage machine in the first bridge of world

Itech stirrup bar bending machine, / pile cage making machine play an important role in bridge and foundation. The longest bridge in the world recorded in the Guinness Book of World Records before 2011 ,it was the Pontchartrain Bridge in the United States, with a total length of 38.4 kilometers.This bridge is located in Louisiana and connects New Orleans and Mandwell.

However, in 2011, the Guinness World Record was refreshed by a newly built bridge in our country China.Its length is more than four times as long as the Pontchartrain Lake Bridge, the world’s largest bridge!

This newly appointed longest bridge in the world is Dankun Bridge.

The Dankun Bridge is located in the Jiangsu on the east coast of China. It starts from Danyang, passes through Changzhou, Wuxi, and Suzhou, and ends in Kunshan.

Because the passing area is the rich southern Jiangsu area with a relatively developed economy, the bridge spans more than 180 roads of various types, making the construction difficult to imagine.

The first bridge of world has a total length of 164.851 kilometers. This length is very shocking. Even if it is driving by, it will take two or three hours!

Itech as one professional steel wire/bar processing machinery China supplier,stirrup bending machine, rebar bending machine,cage making machine,steel wire straightener, wire mesh welding machine,rebar shear line,sawing&threading line and related cnc plasma cutting machine, fiber laser cutting machine can meet different customers’ requirement.https://itechbendingmachine.com/

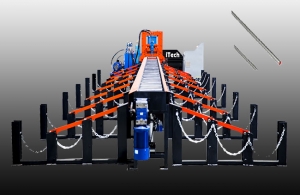

double bending machine

double bending machine automatic rebar stirrup bender

automatic rebar stirrup bender

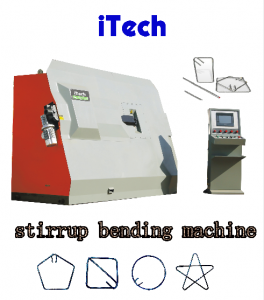

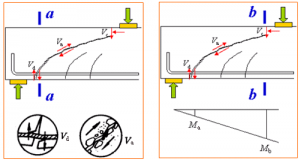

stirrup bending machine

stirrup bending machine

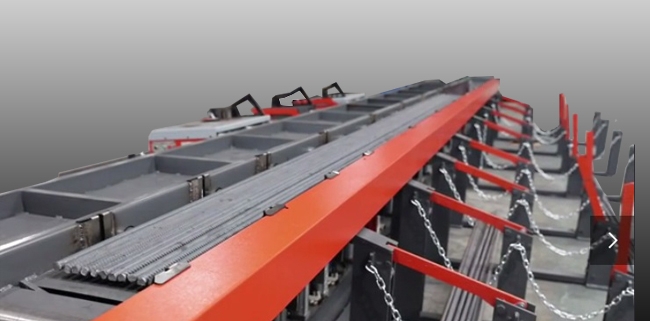

rebar shear and bending line itech

rebar shear and bending line itech

stirrup mkaing machine

stirrup mkaing machine

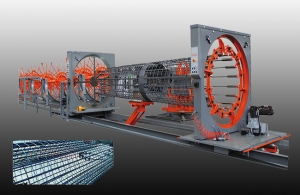

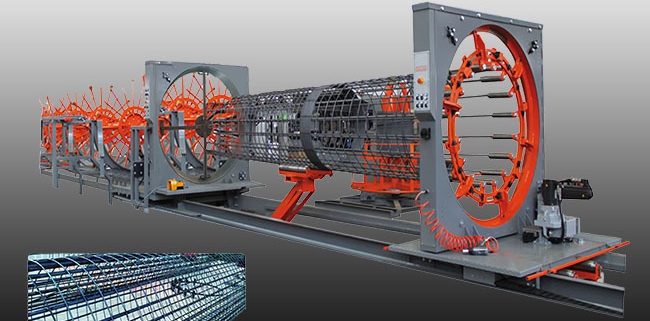

steel pile cage welding machine

steel pile cage welding machine

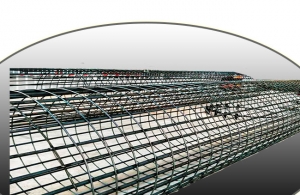

foundation cage

foundation cage