how to use straightening&cutting machine roller type

Straightening&cutting machine roller type use samilar design as automatic steel wire stirrup bending machine. it help improve the steel wire capacity with high speed straightening&cutting machine,widely used in cut&bend factory, construction site, steel factory,wire mesh factory, even build materials shop.Roller type high speed straightening&cutting machine get more and more useful.

- Straightening Process

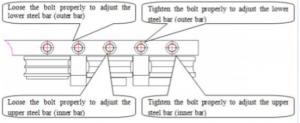

(A) Horizontal Straightening

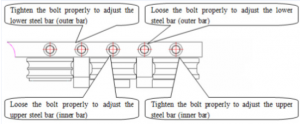

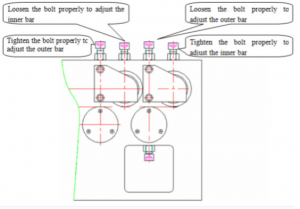

- Straightening principles of horizontal straightening mechanism After steel bar is ready for horizontal straightening, all rollers shall be adjusted to rest gently on steel bar, then the steel bar shall be fed manually for careful observation, and proper adjustment shall be made accordingly during manual operation, as shown below.

- Straightening methods of horizontal straightening mechanism

1) In horizontal straightening mechanism, the upper steel bar (inner bar) bends inwards,and the lower steel bar (outer bar) bends outwards.

2) In horizontal straightening mechanism, the upper steel bar (inner bar) bends outwards,and the lower steel bar (outer bar) bends inwards.

straightening machine

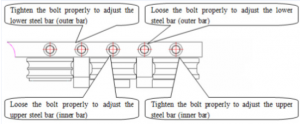

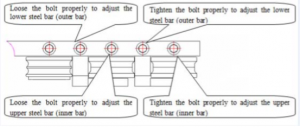

- Both steel bars inhorizontal straightening mechanism bends inwards

- Both steel bars inhorizontal straightening mechanism bends outwards

straightening machine

NOTE:

- Please refer to above straightening method for upper bar (inner bar) insingle-bar straightening mode; during adjustment, adjustment roller for lowersteel bar (outer bar) shall be adjusted in cooperation with adjustment roller of upper steel bar (inner bar) in order to align them with each other.

- During straightening, both adjustment rollers for upper bar shall be adjustedcooperatively, and so do both adjustment rollers for lower bar; if straightenedsteel bars fail to reach requirements (even if all bolts can’t be adjusted any more),all adjustment bolts shall be loosened for re-adjustment till products reach requirements.

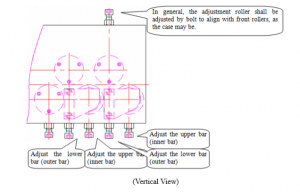

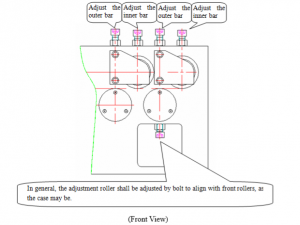

- Vertical Straightening

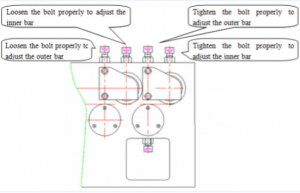

- Straightening principles of vertical straightening mechanism After the steel bar is ready for vertical straightening, all rollers shall be adjusted to restgentlyon the steel bar,then steel bar shall be fed manually for careful observation, and proper adjustment shall be made accordingly during manual operation, as shown below.

straightening&cutting machine

- Straightening methods of vertical straightening mechanism 1) In vertical straightening mechanism, inner bar bends upwards, andouter bar bends downwards.

straightening&cutting machine

- In vertical straightening mechanism, inner bar bends downwards, and the outer bar bends upwards

- Both bars inverticalstraighteningmechanismbend upwards together

4) Both bars in vertical straightening mechanism bend downwards together

straightening&cutting machine

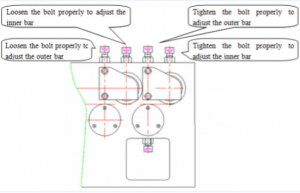

5) If steel bars twist during process (open of stirrup deviates significantly from its normal position), two sets of large front wheels of vertical straightening mechanism shall be compressed tightly(as shown below)

https://itechbendingmachine.com/portfolio_entries/roller-wire-straightening-and-cutting-machine

Roller type straightening&cutting machine as important line, it high capacity, get more more merket.

Itech as one professional steel wire/bar processing machinery China supplier,stirrup bending machine, rebar bending machine,cage making machine,wire mesh welding machine,rebar shear line,saw&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.

http://www.itechbendingmachine.com

spring festival

spring festival

Leave a Reply

Want to join the discussion?Feel free to contribute!