what’s 50 stirrup bending machine and how to use automatic stirrup bender ? automatic stirrup bending machine is for rebar bending and cutting, widly use in constrcution company,cut&bend factory, building materials store, precast factory,industry company.

1 Technical Parameter of automatic stirrup bender

This series of steel bending machine can bend the round steel, carbon steel and rebar of II or III type, which are used in constructional engineering and mechanical processing enterprises.

| Ribbed diameter(mm) |

Ø8-50 [mm] |

| Work low speed |

3 r/min |

| Work high speed |

7 r/min |

| Round speed |

1420 r/min |

| Labeled electric power |

5.5 [KW] |

| Voltage |

380 [V] – 50 [Hz] |

| Machine weight |

700 [Kg] |

| Machine dimension |

1200×900×800 [L*W*H](mm) |

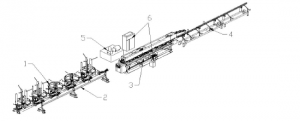

4 External Form of Machine And Working Principle

GW-60 series of round steel bending machines look like the following.

GW series of round steel bending machines look like the above, the labeled parts are explained as the following.

- Feeding Roller 2-Seat 3- Working Disk 4-Button 5- Electrical Control Panel

Feature of automatic stirrup bender

GW series of round steel bending machines are composed of drive gear, rack and workbench. When the machine work, the elect-motor make the gear spin by triangular belt and belt pulley, then the working disk rotate and make the workpiece curve. The series of machines possess some characteristics such as terse structure, reliable performance and novelty appearance, the worker can operate them commodiously. Beyond those, the series of machine have the following.

- Cylindrical bearing installed on the principal axis of GW , it makes the machine no wear and not lubricate.

- Operate the machine by press-button or foot pedal, alternative ways bring handiness.

- Speed regulation by gear brings high efficiency.

- Accessories for bending are thermal refined and have long service life.

5 Installation

5.1 Installation

5.1.1 Lay the machine indoor, take its road-wheels apart, and install it smoothly, make its table-board horizontal.

5.1.2 Put up feeding frame up to the machine’s feeding rotary drum, it’s height isn’t 8mm lower or higher than the feeding rotary drum, and avoid feeding frame to ward off the operating buttons.

6.1.3 Electrical Principle

- The machine need three-phase electric, the value of every phase electric is 380 V.Connect 440v-380v transformer before start.

- Control the machine by button, and provide electric protection measures.

- First plug in, then launch the machine to find if electrical wiring work normally or not.

5.1.4 Before plug in, the earth leakage circuit breaker and default phase protector must be installed. Incorrect operation can cause personal injury or machine breakdown, the above is out of our company’s responsibility.

5.1.5 Make use of the machine for 3 months, remove the speed changing box’s hemi-shell cover, and supply lubricating oil in homologous position to assure the machine function well.

5.1.6 After plugging in, press inching button down to make the machine spin idle, check up if it works normally.

6 Operation

Make use of molding axle-sleeve, axle or sheath for limiting rebar and frame for dominating stuff, all kinds of shape in demand can be made by the GW series bending machines.Put the bending machine in use for a period of time, the operator should rotate the working disk 180 degrees, this can average wear and prolong the service life of the machine. Examples in common use are the followings.

6.2.1 Connect cable and footstep switch

6.2.2 To bend various diameter round steel, the operator should make correct selection about molding axle-sleeve, axle or sheath for limiting rebar and frame for dominating stuff refer to the size dimension of round steel and its ultimate strength.

The position of GW-60 tool for bending round steel (25mm to 60mm and 25mm to 70mm in diameter) is as the following picture shown.

1,2,4-Column Sleeve 3-Newel 5-Plank for steel column 6-Rebar

Notice1; When malfunction occur during the process of machining, please stop the machine and make troubleshooting.

Notice2: Make correct selection about molding axle-sleeve or axle, then install them in the working disk along with suitable shaft-sleeve. In addition to the above, put the frame for dominating stuff into the plank for steel column, then make the machine idle to examine if it work normally. If no defaults, then make it bend the rebar.

6.2.3 Manual mode (the power light is on)

6.2.4 Automatic mode (the power light is off )

1)check working direction

If working direction is not convenient for operator, you can change the working direction.if it is ok, go to next step directy. After power on, the correction value number is Positive number,it mean panel will turn left direction,

the the correction value number is negative number,it mean panel will turn right direction.if want to change the turn direction, press ok

button until the direction changed.

- Modify the phase when set direction is not correct

After set the working direction, press forward or reverse 2 seconds to check if set direction and real direction is not same, then it will modify working direction automatically.the correction value will show 444 and alarm,after 5 seconds ,it will modify and reset itself, when finish, the modify phase succeed.

- Machine parameter checking itself

When working direction and phase are ok, do not put rebar,press set more 2 seconds less 7 seconds, then machine start machine parameter checking itself status. Machine will checking by 90 degree, when finished parameter checking first time, it is no need to do for next time. After long time, operator can use Machine parameter checking itself to adjust machine.

Notice:when press ok more 8 seconds, machine will start warm up status, it will work automatically 99 times.

4) set process and angle

According to stirrups shape,choose the process , if one step can making the stirrups, process is 1, stirrups angle + or – to set the angles. If stirrups need serval step to make it out, set the process and its angle, when set well, press ok.

If want to delet process, press set, choes the process, then press correction.

5 ) Start work

After angle set, press forward or reverse to make panel turn until the correct position, press foot switch one time . the working panel will turn from the process 1 angle,it will back to original position when finished.

6)How to modify angle

When process one stirrup, and its angle not correct, press correction, and press angle + or – to modify the angle.the modify value will show in correction value.

- Set serval stirrups number

Press set, press angle + or – to set stirrups number.

7 Maintenance

The reduction gearbox of GW automatic stirrup bender series machines contains gears and castellated shafts and want lithium-based grease 5~10kg.When it has worked for 3 months, the operator should exchange the lubrication oil in it and do it every three months from then.

Before exchange the lubrication, remove one side of guard board on the machine, then remove the case cover on the reduction gearbox, fill specified lubrication oil to make all mobile parts work normally. Above all, the operator should make irregular inspect about the lubrication when the machine work continuously.

8.2 When the machine is out of service for long-term time, please cut off the general power, put it in storage, cover it and give moisture-proof protection. all parts exposed should be coated with rust-preventative oil.

8.3 After Stop the machine, the users should make the power switch out of service and clean attachments on or in the equipment .If the machine is out of service for long time, please daub rust-preventative oil on these parts for work and cover them.

8 Diagnosis

| Malfunction |

Causes |

Eliminating Methods |

| Alram code 1 |

Stirrup show 1 and flash,the error of the back original angle more than 25 degrees |

Do not put rebar,press foot switch,it will back the position itself and no alarm. |

| Alram code 2222 |

Panel forward turn time more than set time,default is 180,mean 18s can be adjust. |

|

| Alram code 3333 |

Panel reverse turn time more than set time,default is 180,mean 18s can be adjust. |

|

| Alram code 4444 |

Mean pahse direction |

It can modify itself and reset. |

| Alram code 6666 |

Encoder damage |

Replace encoder |

| Alram code 9999 |

Encoder no connect or no turn, |

Press forward or reverse to check if panel can turn or not. If can’t forward turn,check the plug and contactor. |

| 1.Tank oil leakage |

1. oil plug Loose |

1. sturdy |

| 2.damage to the lower bearing cushion or oil seal |

2. replace the oil seal or paper pad |

| 2. Abnormal noise, |

1.lack of oil |

1. add slip oil |

| 3.Larger diameter steel bars are not bent. |

1.belt loosening. |

1.Re-tightening or replacing the V-belt |

| 4.The motor does not work |

1. the power cord is not powered. |

1. check the line |

| 2. contactor contact burnout |

2. replace the contactor or repair |

Notice: machine reset

Press correction until show 888 ,after reset ok, then press correction button one time.

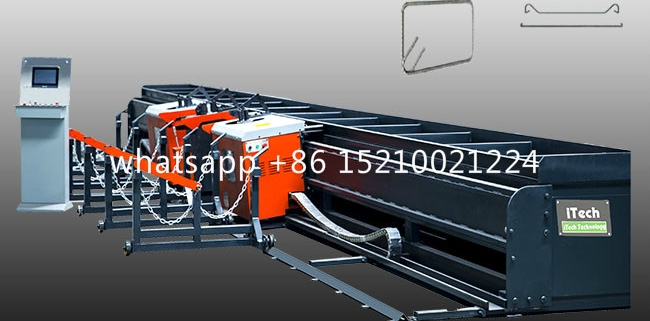

Itech as one professional steel wire/bar processing machinery China supplier,automatic stirrup bender,Stirrup Bending machine,CNC stirrup bar bending machine,stirrup wire bending machine and bar shape machine,cage making machine,,steel wire straightener, wire mesh welding machine,rebar shear line,sawing&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.

steel reinforcement stirrup bending machine

steel reinforcement stirrup bending machine hydraulic bender

hydraulic bender

rebar bender

rebar bender

wire straightening and cutting machine

wire straightening and cutting machine

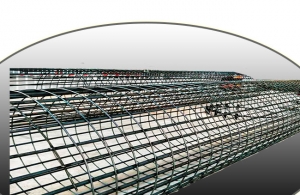

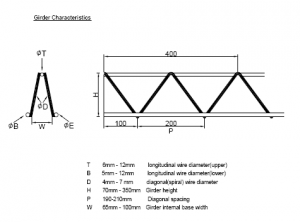

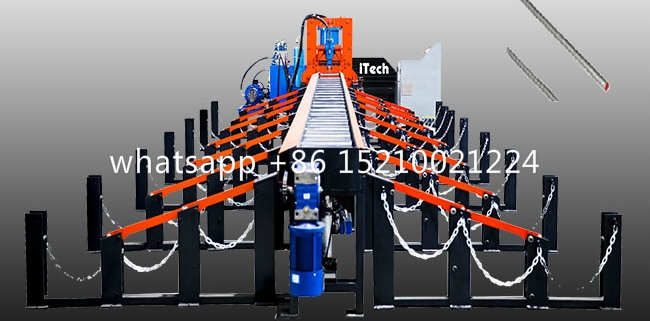

truss gieder welding machine truss girder

truss gieder welding machine truss girder

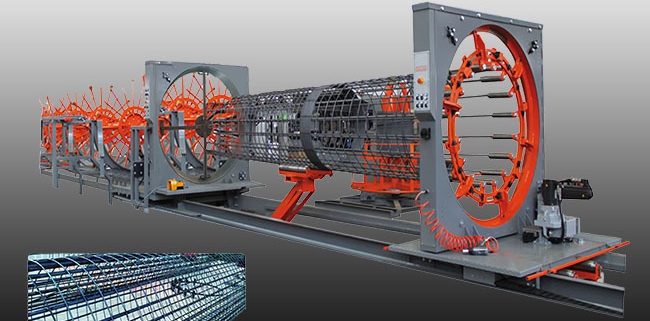

wire mesh machine

wire mesh machine  automatic rebar shear line

automatic rebar shear line

semi automatic stirrup bender

semi automatic stirrup bender

stirrup bender supplier manufacture

stirrup bender supplier manufacture

cold rolling machine

cold rolling machine

rebar double bender

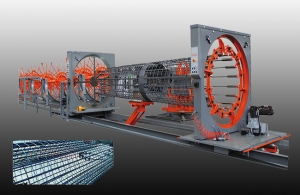

rebar double bender  steel pile cage welding machine

steel pile cage welding machine