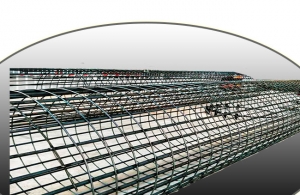

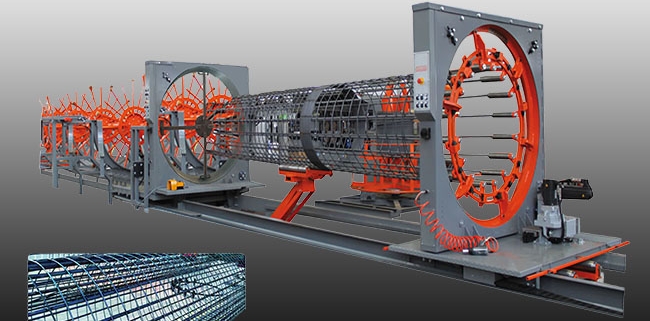

Steel Rebar Pile cage welding machine can be used on piling, column for bridges ,foundation for building

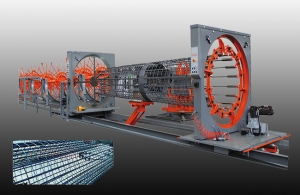

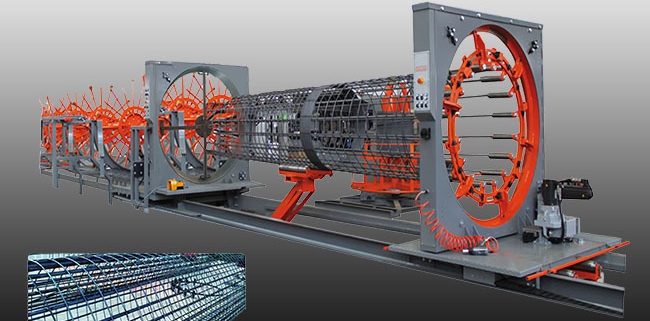

steel Rebar Pile cage welding machine,also called cage making machine, column making machine,it is one of important machine,used cage making machine in cut&bend factory,construction company,foundation company,steel company, and some building materials factory,like wire mesh factory, stirrup making factory. The finish products can be used on piling, column for bridges ,foundation for building etc.

You could also experience the benefit when comparing to traditional pile cage making method.Traditionally pile cage making machine uses the manual rolling or the manual welding. The method is not so efficient.Machine production capacity is 3 ~ 4 times more than traditional manual production capacity. Besides,the main shortcoming is that the quality of the cage is poor and the equipment size is not standard which deeply affects the construction period and quality of project. While steel cage welding machine creates a good economic and social benefits for the construction units and become further development direction of reinforced cage.

You can see it’s uniform, tidy and with high accuracy. For rebar processing manufacturer,cut&bend factory. you can have one automatic cage making machine and make such beautiful works for your clients. And for construction company, you could also have an cage machine and it could help you save labor cost. Any interest please contact me soon!

Steel Pile cage making machine. Usually we weld the cages. But sometimes it can not be welded like in Philippines. And no worries, the welding method can be changed to tie the cages.

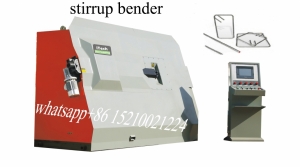

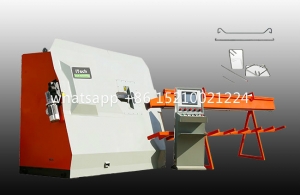

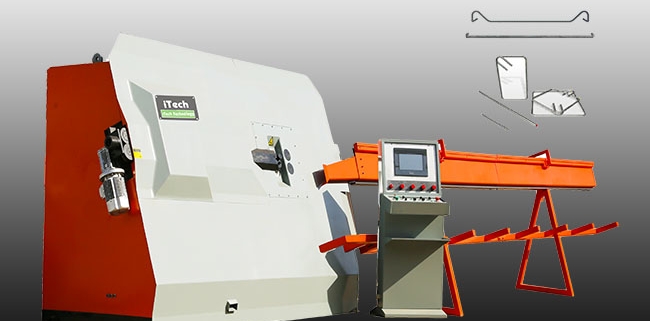

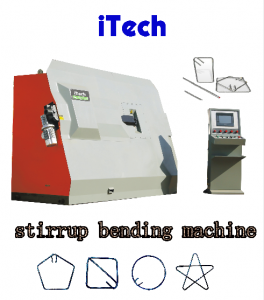

Itech is best steel wire/bar processing machinery China supplier,stirrup bending machine, rebar bending machine,Rebar Pile cage welding machine,cage making machine,,steel wire straightener, wire mesh welding machine,rebar shear line,sawing&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.

steel pile cage welding machine

steel pile cage welding machine

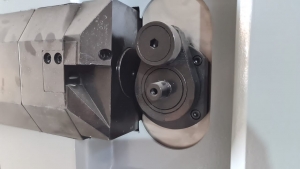

16mm stirrup bender

16mm stirrup bender

pile cage making machine

pile cage making machine

itech

itech

rebar pile cage machine

rebar pile cage machine

stirrup bending machine price in Sri lanka,automatic stirrup rebar bending machine for sale

stirrup bending machine price in Sri lanka,automatic stirrup rebar bending machine for sale