Reinforcement steel rebar double bending machines rebar forging machine rebar shaping machine

Reinforcement steel rebar double bending machines rebar forging machine rebar shaping machine

Rebar double bending machines are essential tools in the construction industry for bending and forming steel bars accurately and efficiently. Thoes rebar machines also are important rebar process equipment in steel rebar cut and bend factory. These machines are designed to handle the difficult task of bending steel bars, a key component of reinforced concrete structures. In this blog, we will explore the features, benefits, and considerations of a rebar double bending machines.

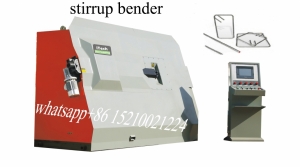

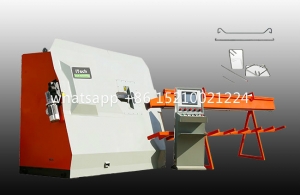

Itech Best selling CNC high quality automatic stirrup bending machine / CNC stirrup bender machine widely use in reinforcement steel wire bar cut and bend factory. Itech as professional reinforcing steel machine supplier. Itech have a series of steel rebar bender machine,like CNC 16mm Stirrup Bending machine,CNC 20mm stirrup bar bending machine , 14mm stirrup wire bending machine and bar shape machine ,automatic rebar pile cage welding machine,cnc automatic pile cage making machine and many kinds of rebar machine. To solve the gap on the stirrups ,Itech stirrup bending machine adopt advanced anti twist feeding system to avoid twist of steel, make stirrup more quick and standard.Shape and bend stirrups effortlessly with our cutting-edge bending machine.

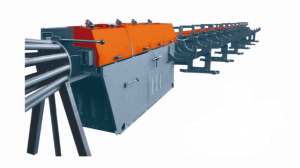

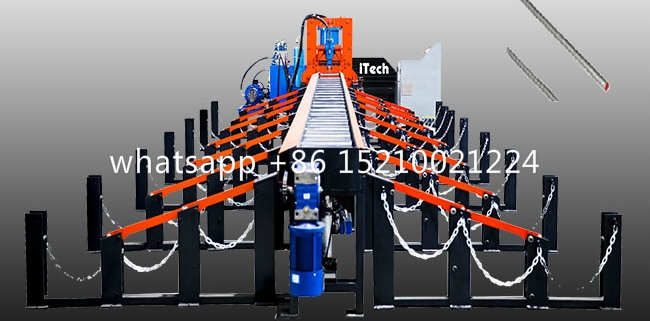

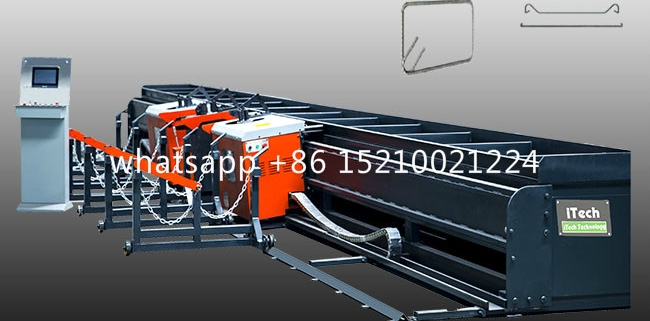

Reinforcement Steel bar horiontal double bending machines is specially designed to bend steel bars into various shapes and angles, such as straight bends, curved bends and stirrup bends. These machines are equipped with powerful motors and precision bending mechanisms that can handle steel bars of different diameters and lengths. The dual bending machine feature increases the productivity and versatility of bending operations, making it ideal for construction projects of all sizes.

Using a reinforcing rebar steel bender machine provides construction professionals with multiple benefits. First, these machines significantly reduce the physical labor and risk of injury associated with bending rebar by hand. The precision and consistency of the bends produced by these machines ensure that the steel bars meet the specifications required for structural integrity. Additionally, the efficiency of a double press brake saves time and costs, making it a valuable investment for construction companies.

Reinforcement steel rebar double bending machines rebar forging machine rebar shaping machine.When considering purchasing a precast rebar double bending machine, there are several factors to consider. The capacity and functionality of the machine should be consistent with the specific requirements of the construction project in which it is used. It is important to consider the maximum bending diameter the machine can produce, the bending speed and the type of bend. In addition, the durability and reliability of the machine as well as the availability of technical support and spare parts should be carefully evaluated.

In conclusion, the concrete rebar robot bender machine is an indispensable tool for construction professionals, providing efficient, precise and versatile rebar bending. By understanding the features, benefits, and considerations of these machines, construction companies can make informed decisions when investing in this important equipment. With the right steel double bending machine, construction projects can be completed with greater efficiency and quality, ultimately contributing to the success of the entire project.

Itech is professional steel wire/bar processing machinery China supplier,stirrup bending machine price , steel rebar robot bender machine,foundation pile cage making machine,,steel wire straightener,wire straightening and cutting machine, wire mesh welding machine,rebar shear line,rebar sawing&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.

rebar double bending machine

rebar double bending machine steel reinforcement stirrup bending machine

steel reinforcement stirrup bending machine rebar shear and bend line

rebar shear and bend line

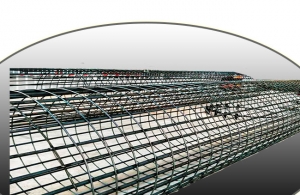

rebar pile cage machine

rebar pile cage machine

stirrups bender

stirrups bender

automatic rebar shear line

automatic rebar shear line

rebar double bender

rebar double bender

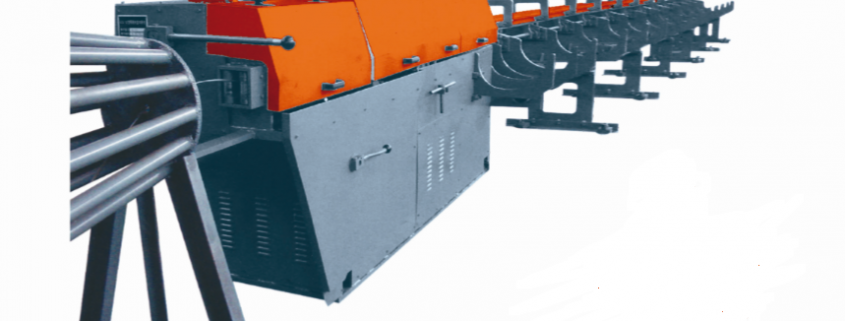

wire straightening and cutting machine

wire straightening and cutting machine

high speed straightening machine

high speed straightening machine