automatic reinforcement steel bar cutting lines rebar shear line in steel cut and bend factory and Infrastructure construction

automatic reinforcement steel bar cutting lines rebar shear line in steel cut and bend factory and Infrastructure construction

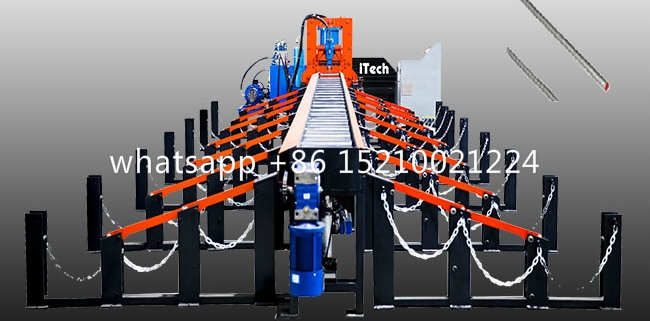

In the steel cut&bend factory and construction industry, efficiency and precision are key factors in ensuring structural quality and durability. One of the important components in construction is reinforcing steel bars, which provide strength and stability to concrete structures. To simplify the process of steel rebar cutting and forming , the use of automatic rebar cutting lines rebar shear line has become increasingly popular. This innovative technology offers a range of benefits that help improve the overall efficiency and quality of construction projects.

Itech Best selling CNC high quality automatic stirrup bending machine / CNC stirrup bender machine widely use in reinforcement steel wire bar cut and bend factory. Itech as professional reinforcing steel machine supplier. Itech have a series of steel rebar bender machine,like CNC 16mm Stirrup Bending machine,CNC 20mm stirrup bar bending machine , 14mm stirrup wire bending machine and bar shape machine ,automatic rebar pile cage welding machine,cnc automatic pile cage making machine and many kinds of rebar machine. To solve the gap on the stirrups ,Itech stirrup bending machine adopt advanced anti twist feeding system to avoid twist of steel, make stirrup more quick and standard.Shape and bend stirrups effortlessly with our cutting-edge bending machine.

One of the main advantages of automatic reinforcement steel bar cutting lines rebar shear line is their ability to increase productivity. By automating the rebar cutting and forming process, Shear Line significantly reduces the time and labor required for these tasks. This not only speeds up the construction process, but also allows more steel to be processed in less time. As a result, construction projects can be completed more efficiently, resulting in cost savings and shorter project durations.

In addition to increasing productivity, automatic rebar shearing lines increase the precision and accuracy of rebar cutting and forming. Advanced technology and computerized control of the shear lines ensure that each steel bar is cut to the precise specifications required for the construction project. This level of precision is critical to ensuring the structural integrity of the final product, as any inaccuracies in rebar cutting and shaping can compromise the strength and stability of the concrete structure.

Additionally, the use of automated rebar shearing lines helps provide a safer working environment for construction workers. By automating the cutting and forming process, the need for manual handling of heavy steel bars is significantly reduced, minimizing the risk of injuries and accidents on the construction site. This not only protects the well-being of construction workers, but also helps maintain a more efficient and organized work environment.

the use of automated steel bar shearing lines brings many benefits to the construction industry. From increased productivity and precision to improved safety and versatility, this innovative technology plays a vital role in improving the efficiency and quality of construction projects. As the demand for sustainable and durable structures continues to grow, the use of automated steel shear lines will undoubtedly become an integral part of modern Infrastructure construction practice.

Itech is professional steel wire/bar processing machinery China supplier,stirrup bending machine price , steel rebar bending machine,foundation pile cage making machine,,steel wire straightener,wire straightening and cutting machine, wire mesh welding machine,rebar shear line,rebar sawing&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.

automatic rebar shear line

automatic rebar shear line

automatic rebar shear line

automatic rebar shear line stirrups bender

stirrups bender

Leave a Reply

Want to join the discussion?Feel free to contribute!