Handle hydraulic bender straightening machine user manual

- Uses and advantages

As one of the on-site steel bending equipment commonly used in construction sites, small hydraulic steel bar bending machines are mainly used to bend rebar, round steel, screw rods, etc., and are widely used in highways, railways, bridges, hydro-power projects, and housing construction. in an industry. With the advantages of light weight, small size, easy to carry and easy to operate, it is an on-site steel bar bender widely used by many road and bridge companies and water conservancy and housing construction companies in recent years.

Handle hydraulic bender and straightening machine advantage;

1) The overall structure is simple, easy to operate and use. Good stability and high reliability ensure the quality of steel bending and improve work efficiency;

2) It is suitable for on-site operations such as parts that are difficult for ordinary bending machines to reach after steel bar binding or concrete pouring;

3) Driven by a high-pressure hydraulic system, the bending force is large, and 32MM steel bars can be bent;

4) The machine does not need to replace the working head, and can perform steel bar bending and straightening work. Bending, straightening fast;

5) The machine is easy to operate, labor-saving and easy to move. Portable steel bar bending machine straightening machine is especially suitable for mobile operations in steel bar processing workshops or construction sites.

6) In the field of bridge pile foundation, the head cage hook at the connection between the reinforcement cage and the cap is 90 degrees and 180 degrees;

- matters needing attention:

1) When bending steel, first close the oil circuit switch, pull the movable handle, make the plunger and pump start to work, and make the oil pressure push the big piston to advance the cutter shaft;

2) The oil pump uses No. 46 hydraulic oil.

3) The oil storage capacity must be within the range above the oil window.

4) When refueling or changing oil, it must be filtered with an oil filter net of 80 mesh or more, and the oil tank must be cleaned when changing. The oil change period is six months.

5) The working oil temperature is 10 degrees Celsius to 50 degrees Celsius.

6) Before starting the electric pump, it is necessary to open the vent nut, open the switch and put it in the unloading position.

7) If the temperature of the motor is found to be too high during use, stop using it. Allow to cool before use.

8) The pump has been adjusted before leaving the factory and should not be adjusted arbitrarily. When it needs to be readjusted, it must be carried out with the help of a pressure gauge.

9) The high-pressure oil pipe has passed the 105MPA test before leaving the factory. However, because the rubber hose is easy to age, users need to check it frequently, usually for six months, and for frequent use for three months. During the inspection, 87.5MPA pressure test, if there is damage, bulge, or leakage, it cannot be used.

10) Bearings are generally cleaned once every six months, and grease must be added during assembly.

- Parameter

Model: WT-32

Bending and straightening angle: 90 degrees/180 degrees (optional)

Cylinder thrust: 15T-20T

Electric oil pump power: 1.5KW

Bar range: 14-32

Straightening angle: ≤90 degrees or ≤180 degrees

Operating pressure: 30-70MPA

Product composition of portable steel bar bending machine:

- Ultra-high pressure electric oil pump.

- Portable hydraulic steel bar bending machine

- Two 5-meter-long 70Mpa high-pressure oil pipes are standard.

- operation method

- Remove the package and check whether the appearance of the machine is intact,

- Fill the electric oil pump with hydraulic oil. In winter, it is recommended to add No. 32 anti-wear hydraulic oil. In other seasons, it is recommended to add No. 46 anti-wear hydraulic oil. The amount of oil can be filled to the upper middle of the liquid level gauge on the side of the fuel tank. . Fuel tank capacity 16 liters

- Ask a professional electrician (remember!!!) to connect the power supply (380V), and pay attention to theclockwise rotation direction of the motor.

- Connect the high-pressure oil pipe, 2 joints of the bending machine, and 2 joints of the electric oil pump.

- Regarding the description of the manual reversing valve, the manual reversing valve hasthree gearsin total, which are (A O B position-) (middle O position-stop). !!). Special reminder, before starting the motor, the manual reversing valve should be pulled to the position (middle O stop position).

6 Start the motor, turn the reversing valve left and right, let the piston of the bending machine run idly back and forth for 3 times, and drain the air in the oil cylinder of the bending machine.

7 All ex-factory products are not damaged by human beings, and the warranty period is one year.

8 when change oil tube, make handle in O position(middle position).

5.portable steel bending machine maintenance and maintenance

- Hydraulic oil circuit

1) Check the oil level of the fuel tank every week. If the hydraulic system is repaired, it should also be checked. If the oil level is lower than the center of the oil mark line, hydraulic oil should be filled;

2) The hydraulic oil used in this machine is 46# hydraulic oil;

3) The oil of the new machine should be changed after 2000 hours of operation, and the hydraulic oil should be replaced after every 4000-6000 hours of operation, and the oil tank should be cleaned every time the oil is changed;

4) The oil temperature of the system should be between 35°C and 60°C, and should not exceed 70°C. If it is too high, it will cause deterioration of oil quality and accessories.

- Handle Hydraulic bender straightening machine components

1) Clean the hydraulic components (valve, motor, pump, oil pipe, etc.) every month to prevent dirt from entering the system and do not use detergent;

2) After the new machine has been used for one month, check whether there is any deformation at the bends of the oil pipes. If there is any abnormality, it should be replaced. After two months of use, the connections of all accessories should be tightened. pressure.

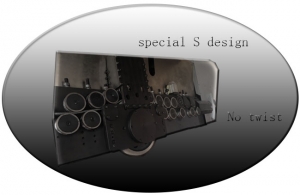

We have a series of steel rebar bender machine,like CNC 16mm Stirrup Bending machine,CNC stirrup bar bending machine,stirrup wire bending machine and bar shape machine.advanced anti twist feeding system to avoid twist of steel, make stirrup more quick and standard. Rebar cutting system is used multi-faceted with a knife design. With international servo drive, high speed to feeding,big production capacity was highly improved.

6 fault:

| fault |

Reason |

Solution |

| not working properly |

cannot bend or straighten |

Check power, switch |

| Bending, slow straightening |

Check whether the wiring in the junction box is fixed:

Whether the capacitor is damaged:

Whether the three-phase electricity lacks a phase: |

| Abnormal hydraulic pump pressure |

High Pressure Relief Valve Out of Adjustment |

Adjust the high pressure relief valve |

| Manual magnetic valve oil leakage |

Clean the inside of the valve block and the solenoid core |

| plunger wear |

replace plunger |

| Pump body seal bolt oil leakage |

Tighten bolts or replace gaskets |

| Abnormal hydraulic oil |

Part of the plunger does not work |

cleaning oil pump |

| Hydraulic oil solubility is too high |

Change hydraulic oil |

| High pressure distributed valve oil leakage |

Grinding the seat and replacing the spool |

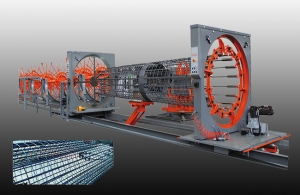

cage welding machine

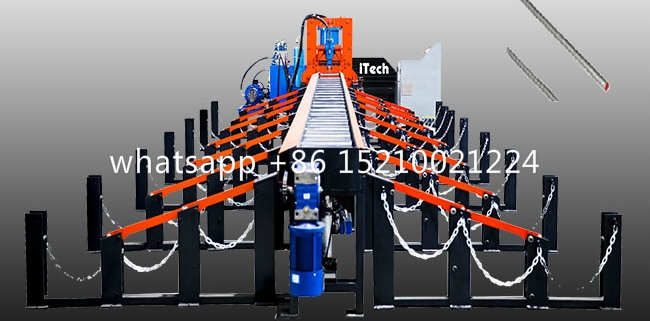

cage welding machine automatic rebar shear line

automatic rebar shear line

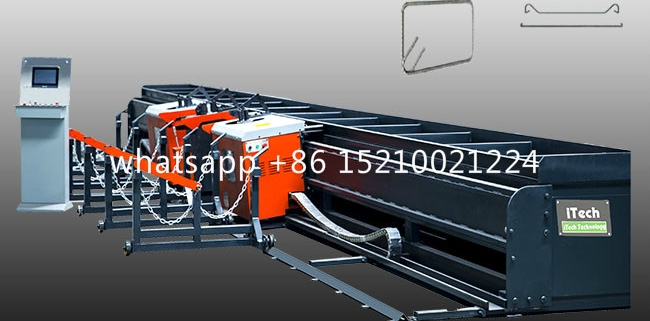

rebar bender

rebar bender

rebar double bender

rebar double bender

steel reinforcement stirrup bending machine

steel reinforcement stirrup bending machine

hydraulic bender

hydraulic bender