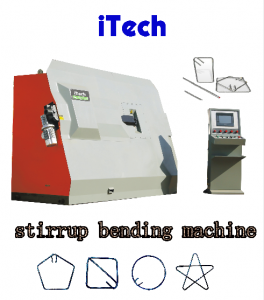

stirrup rebar bending machine high quality China supplier price

ITECH stirrup rebar bending machine installed successfully in middle east iraq oversea customer factory

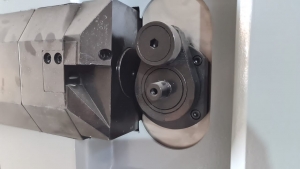

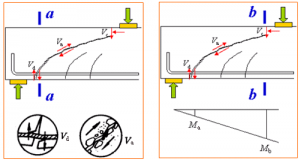

iTECH stirrup rebar bender machine (also called stirrup bender) can process steel wire in coil 6-12mm. Congratullations to our itech oversea middle east Iraq customer to install stirrup bending machine successfully. Double wire feeding 6-10mm, single wire process two wire feeding one time, so the capacity can be double. Like if single wire, 6-12mm, di-direction.automatic stirrup rebar bender machine use anti-twist design,

It make stirrup making more easy and most accurate.

Rebar stirrup bender wildly use in cut&bend factory, precast factory, construction company, high speed way, construction site,bridge, real estate, reinforcing steel processing factories area. stirrup rebar bender machine is capable of providing our products by the most accurate cutting , straightening, bending and effect.

Itech as one professional steel wire/bar processing machinery China supplier,,stirrup wire bending machine , rebar bending machine,cage making machine,wire mesh welding machine,rebar shear line,saw&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.

Our website:http://www.itechbendingmachine.com

Whastapp:+8615210021224

Welcome to learn about itech steel bar/ wire procecssing machinery.

automatic rebar stirrup bender

automatic rebar stirrup bender

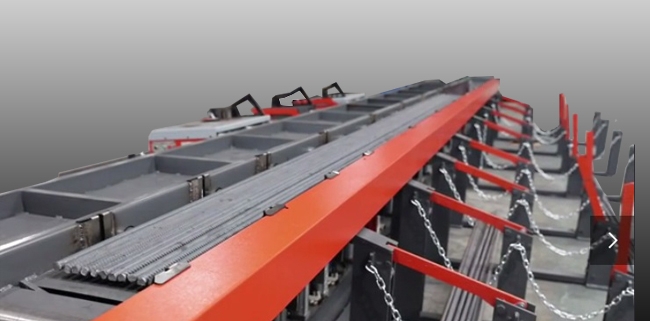

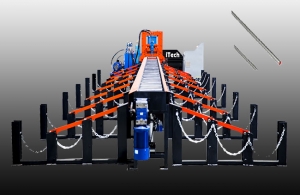

rebar shear and bending line itech

rebar shear and bending line itech

stirrup mkaing machine

stirrup mkaing machine

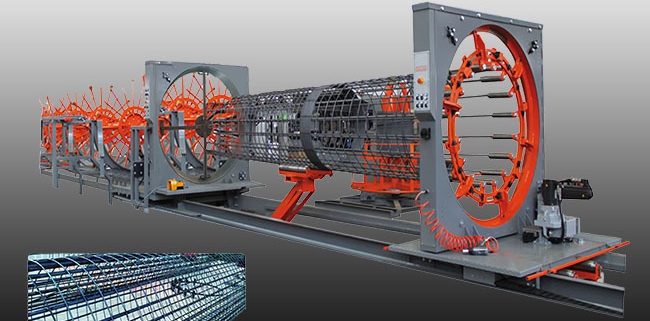

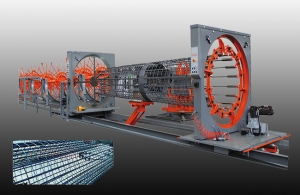

steel pile cage welding machine

steel pile cage welding machine

Afghanistan

Afghanistan

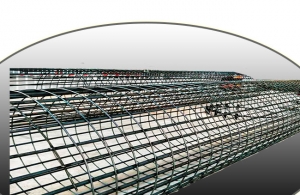

foundation cage

foundation cage

steel bending machine

steel bending machine rebar stirrup bender

rebar stirrup bender