World class construction trade show -Las Vegas trade shows 2026 is coming

World class construction trade show -Las Vegas world of concrete trade shows 2026 is coming

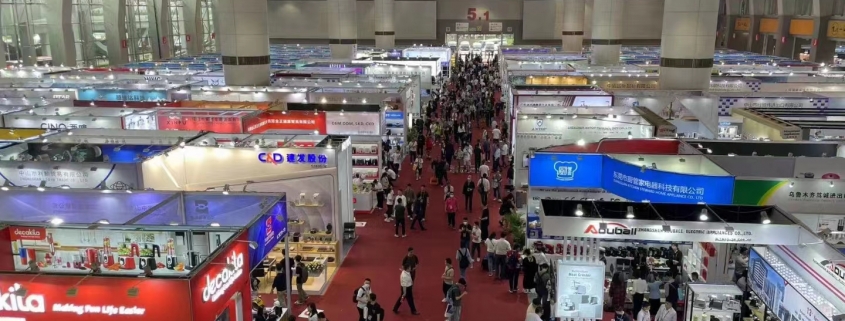

contractors, builders, and fabricators, steel cut and bend factory, it is well known the Las Vegas World of Concrete. It is renowned as the premier destination for major trade shows, and in 2026, it will once again host the highly anticipated 2026 Las Vegas Concrete Show, officially known as the World of Concrete (WOC). As the leading international trade event dedicated exclusively to the commercial concrete and masonry industries, WOC 2026 offers unparalleled opportunities for contractors, engineers, manufacturers, and construction professionals worldwide to connect, learn, and discover cutting-edge innovations.

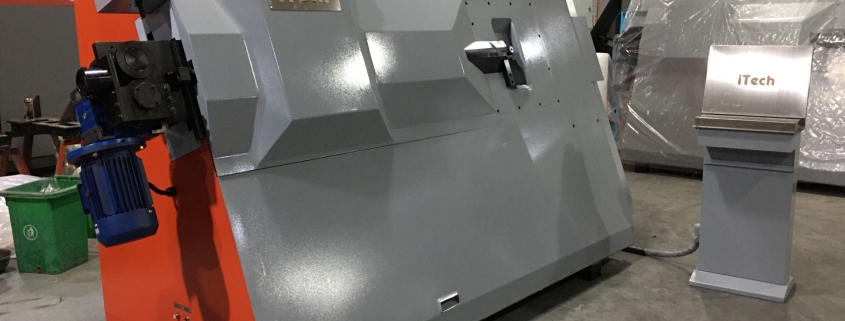

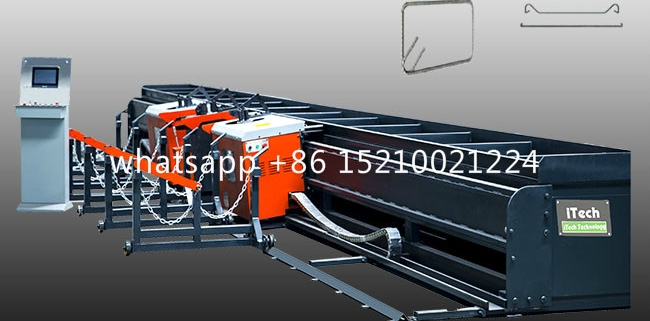

itech as leading steel rebar processing machine supplier, Las Vegas World of Concrete is also opportunity for itech rebar machine. Itech Best selling CNC high quality automatic stirrup bending machine / CNC stirrup bender machine widely use in reinforcement steel wire bar cut and bend factory. Itech as professional reinforcing steel machine supplier. Itech have a series of steel rebar bender machine,like CNC 16mm Stirrup Bending machine,CNC 20mm stirrup bar bending machine , 14mm stirrup wire bending machine and bar shape machine ,automatic rebar pile cage welding machine,cnc automatic pile cage making machine , automatic truss lattice girder welding machine and many kinds of rebar machine. To solve the gap on the stirrups ,Itech stirrup bending machine adopt advanced anti twist feeding system to avoid twist of steel, make stirrup more quick and standard.Shape and bend stirrups effortlessly with our cutting-edge bending machine.

What is the 2026 Las Vegas Concrete Show?

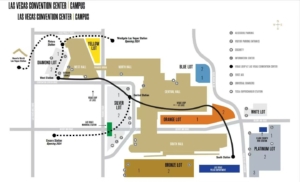

The World of Concrete 2026 is the industry’s only annual international trade show focusing on commercial concrete and masonry construction. Scheduled for January 20-22, 2026, at the Las Vegas Convention Center, this event attracts over 50,000 industry professionals and features more than 1,400 exhibiting companies across 700,000+ square feet of indoor and outdoor exhibit space.

The show combines extensive exhibits with educational programs, live equipment demonstrations, and skill competitions, making it a must-attend for anyone involved in concrete construction.

Why Attend World of Concrete 2026?

Attending the 2026 Las Vegas Concrete Show offers numerous benefits for professionals looking to stay ahead in the competitive construction industry:

Innovative Product Launches: Discover the latest tools, materials, and technologies driving the concrete and masonry sectors forward.

Networking Opportunities: Connect with top manufacturers, suppliers, contractors, and industry leaders from around the globe.

Hands-On Demonstrations: Experience live equipment demos and skill challenges that showcase practical applications.

Educational Sessions: Gain insights from industry experts on emerging trends, business strategies, and technological advancements.

Global Reach: Engage with a qualified audience of contractors, architects, engineers, and distributors seeking solutions.

- Key Features of World of Concrete 2026

Advanced Construction equipment: China itech, italy mep, italy schnell, Mbk all are rebar processing machine supplier.

Exhibit Space: Over 700,000 square feet featuring indoor and outdoor exhibits.

Exhibitors: More than 1,400 companies showcasing products from admixtures and coatings to heavy machinery and robotics.

Attendees: 50,000+ professionals including commercial contractors, decorative concrete specialists, and construction managers.

Education: Sessions running January 19-22, covering technology, applications, and business growth strategies.

Event Highlights: New Product Zone, live competitions, and networking receptions.

High-quality rebar machines from manufacturers itech offer CNC servo controls with ±0.5° bending accuracy and ±1 mm length precision. This ensures every stirrup meets strict construction standards, reducing material waste and rework.

Why Las Vegas is the Ideal Host for WOC 2026

Las Vegas dominates the U.S. convention landscape with nearly 6 million convention attendees annually and an economic impact of $87.7 billion. The city’s infrastructure is engineered for efficiency with venues like the Las Vegas Convention Center offering advanced logistics, 24-hour dock operations, and skilled local crews. These factors ensure smooth installations and predictable timelines for exhibitors.

For companies planning trade show booth rentals, partnering with local exhibit rental providers in Las Vegas can maximize visibility and operational ease during WOC 2026.

How to Make the Most of Your WOC 2026 Experience

- Reserve Your Booth Early: Secure prime exhibit space to showcase your products effectively.

- Leverage Educational Programs: Attend workshops and seminars to enhance your industry knowledge.

- Engage in Live Demonstrations: Participate or observe to understand practical applications of new technologies.

- Network Strategically: Build relationships with decision-makers and potential partners.

- Utilize Trade Show Booth Rentals: Work with experienced local vendors to create a standout booth without the hassle of ownership.

Conclusion: Don’t Miss the 2026 Las Vegas Concrete Show

The 2026 Las Vegas Concrete Show is more than just a trade event—it’s the ultimate platform for growth, innovation, and networking in the commercial concrete and masonry industries. Whether you’re a contractor, supplier, or manufacturer, WOC 2026 offers the tools and connections to elevate your business.

Prepare now to attend or exhibit at this landmark event, and leverage Las Vegas’s world-class infrastructure to make your participation a resounding success.

Ready to break new ground at rebar cut and bend business? Visit the itech rebar machine website, explore more opportunities, and contact us today!

rebar bender

rebar bender

steel reinforcement stirrup bending machine

steel reinforcement stirrup bending machine

stirrups bender

stirrups bender  cut and bend machine

cut and bend machine

rebar stirrup bender

rebar stirrup bender  stirrup bender

stirrup bender  cut and bend

cut and bend Concrete Show South East Asia - itech rebar cut and bend machine China manufacture & supplier

Concrete Show South East Asia - itech rebar cut and bend machine China manufacture & supplier rebar double bender

rebar double bender

concrete show south america

concrete show south america