Revolutionizing Construction: The Role of Automatic Pile Cage Machine in Foundation drilling Equipment

Revolutionizing Construction: The Role of Automatic Pile Cage Machine in Foundation drilling Equipment

automatic pile cage machine—a game-changer in foundation drilling equipment. Used Automatic pile cage machine mostly in foundation drilling company,reinforcement cut and bend factory, building materials factory. This innovative technology is transforming how pile cages are manufactured, offering significant advantages in terms of speed, accuracy, and cost-effectiveness. Whether you’re a construction professional or an industry enthusiast, understanding the capabilities and benefits of these machines can provide a competitive edge.

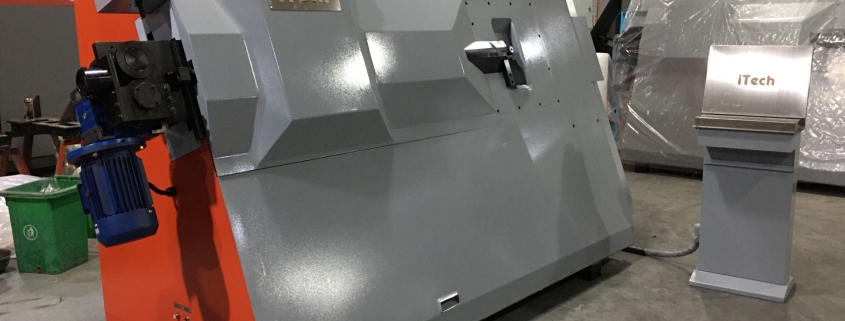

itech Best selling CNC high quality automatic stirrup bending machine / CNC stirrup bender machine widely use in reinforcement steel wire bar cut and bend factory. Itech as professional reinforcing steel machine supplier. Itech have a series of steel rebar bender machine,like CNC 16mm Stirrup Bending machine,CNC 20mm stirrup bar bending machine , 14mm stirrup wire bending machine and bar shape machine ,automatic rebar pile cage welding machine,cnc automatic pile cage making machine and many kinds of rebar machine. To solve the gap on the stirrups ,Itech stirrup bending machine adopt advanced anti twist feeding system to avoid twist of steel, make stirrup more quick and standard.Shape and bend stirrups effortlessly with our cutting-edge bending machine.

What is an Automatic Pile Cage Machine?

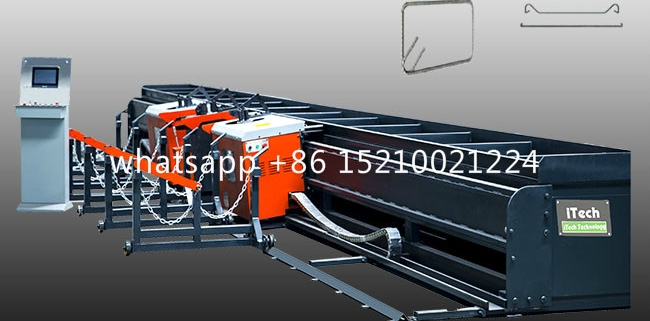

automatic pile cage machine is a sophisticated piece of equipment used to fabricate reinforcement cages for concrete piles. These machines automate the welding and assembly process, producing high-quality cages with minimal labor. The integration of CNC technology allows for precise control over the design and dimensions of the cages, catering to various construction needs.

Key Features and Benefits

Enhanced Productivity: Automatic pile cage machines significantly reduce the time and labor required to produce reinforcement cages. With features like programmable settings and automated welding, these machines can operate continuously, increasing output and efficiency.

Precision and Consistency: The use of CNC technology ensures that each cage is manufactured to exact specifications. This precision minimizes errors and waste, leading to more consistent quality in construction projects.

Cost-Effectiveness: By reducing the need for manual labor and increasing production speed, automatic pile cage machines lower overall project costs. The initial investment in these machines is quickly offset by savings in labor and material costs.

Versatility: These machines can produce a wide range of cage sizes and shapes, accommodating different construction requirements. Whether for cylindrical, square, or custom-shaped cages, automatic pile cage machines offer unmatched flexibility.

Automatic Pile Cage Machine in Foundation drilling Equipment Industry Insights and Trends

According to top suppliers on platforms like itech, the demand for automatic pile cage machines is on the rise. itech emphasize the machines’ ability to handle different wire diameters and cage lengths, catering to diverse project needs.

Leading Suppliers and Products

Itech rebar cage machine Series: series offers a range of models with varying capacities, from the compact300 to the robust 2500. These machines are celebrated for their high productivity and user-friendly controls.

Itech cage Pile Fab: This machine features smart assistance technology, enabling efficient fabrication with minimal labor. Its advanced software and motorized welding robot ensure high-quality welds and easy operation.

How to Choose the Right Machine

When selecting an automatic pile cage machine, consider factors such as:

Project Requirements: Determine the cage sizes and shapes needed for your projects.

Budget: Evaluate the cost versus the expected return on investment.

Supplier Reputation: Choose reputable suppliers with positive reviews and reliable after-sales support.

Conclusion

Automatic pile cage machines are revolutionizing the construction industry by enhancing efficiency, precision, and cost-effectiveness. As more companies recognize the benefits of these machines, their adoption is set to increase, driving innovation and quality in construction projects. For those looking to stay ahead in the competitive construction landscape, investing in an automatic pile cage machine could be a strategic move. Explore the latest models and suppliers to find the perfect fit for your needs and elevate your construction capabilities.

Itech is professional steel wire/bar processing machinery China supplier,stirrup bending machine price , steel rebar bending machine,foundation pile cage making machine,,steel wire straightener,wire straightening and cutting machine, wire mesh welding machine,rebar shear line,rebar sawing&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.

For further information and to explore a wide range of automatic pile cage machines, visit leading suppliers itech. Embrace the future of construction technology today!

pile cage machine

pile cage machine

rebar bend and cut factory

rebar bend and cut factory  rebar bender

rebar bender  wire straightening and cutting machine

wire straightening and cutting machine rebar double bender

rebar double bender

steel reinforcement stirrup bending machine

steel reinforcement stirrup bending machine rebar bender

rebar bender  stirrups bender

stirrups bender

wire mesh

wire mesh