Automatic reinforcement steel fabrication stirrup benders machine spare parts sent to Thailand

Automatic reinforcement steel fabrication stirrup benders machine spare parts sent to Thailand

Automatic reinforcement steel fabrication stirrup bending machine spare parts sent to Thailand.Automatic stirrup bender machines are designed to bend and cut steel bars, it is use in construction project, reinforced concrete,precast company,rebar cut and bend factory. These machines are capable of producing a variety of shapes and sizes of stirrups, making them versatile and adaptable to different construction requirements.

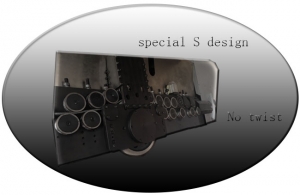

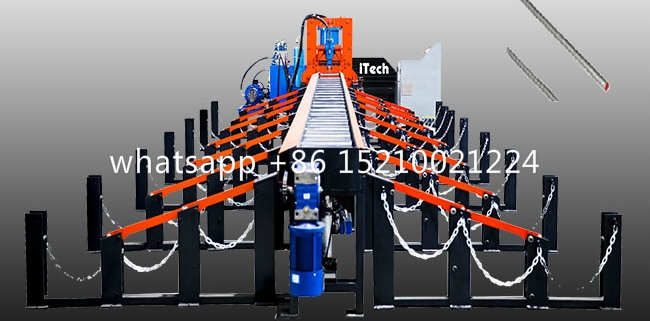

Itech Best selling CNC high quality automatic stirrup bending machine / CNC stirrup bender machine widely use in reinforcement steel wire bar cut and bend factory. Itech as professional reinforcing steel machine supplier. Itech have a series of steel rebar bender machine,like CNC 16mm Stirrup Bending machine,CNC 20mm stirrup bar bending machine , 14mm stirrup wire bending machine and bar shape machine ,automatic rebar pile cage welding machine,cnc automatic pile cage making machine and many kinds of rebar machine. To solve the gap on the stirrups ,Itech stirrup bending machine adopt advanced anti twist feeding system to avoid twist of steel, make stirrup more quick and standard.Shape and bend stirrups effortlessly with our cutting-edge bending machine.

One of the key advantages of using automatic stirrup benders machines is the significant increase in productivity and efficiency. These machines are capable of bending and cutting steel bars at a much faster rate than manual methods, reducing the time and labor required for these tasks. This not only speeds up the construction process but also allows for a higher volume of production, ultimately leading to cost savings for construction companies.

In addition to speed and efficiency, automatic stirrup bending machines also offer a high level of precision and accuracy in the production of stirrups. The computerized controls and advanced technology used in these machines ensure that each stirrup is produced to the exact specifications required, minimizing errors and waste. This level of precision is crucial in ensuring the structural integrity and safety of the reinforced concrete in construction projects.

Furthermore, automatic stirrup rebar bender machines contribute to a safer working environment for construction workers. By automating the bending and cutting process, these machines reduce the need for manual handling of steel bars, which can be physically demanding and pose a risk of injury. This not only improves the overall safety of the construction site but also enhances the well-being of the workers involved.

Another significant advantage of using automatic stirrup bending machines is the flexibility they offer in terms of customization. These machines can be programmed to produce a wide range of stirrup shapes and sizes, allowing for greater design flexibility in construction projects. Whether it’s standard stirrups, spiral shapes, or custom designs, automatic stirrup bender machines can accommodate various requirements, making them a valuable asset in the construction industry.

In conclusion, Automatic reinforcement steel fabrication stirrup benders machine spare parts sent to Thailand. the use of automatic rebar bender machines has become increasingly prevalent in the construction industry due to the numerous advantages they offer. From increased productivity and precision to improved safety and flexibility, these machines have proven to be a game-changer in the way steel reinforcement is handled in construction projects. As technology continues to advance, it is clear that automatic stirrup bender machines will remain an essential tool for enhancing the efficiency and quality of construction processes.

Itech is professional steel wire/bar processing machinery China supplier,stirrup bending machine price , steel rebar bending machine,foundation pile cage making machine,,steel wire straightener,wire straightening and cutting machine, wire mesh welding machine,rebar shear line,rebar sawing&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.

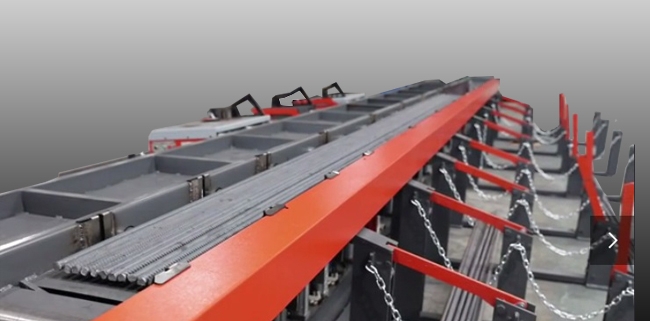

steel reinforcement stirrup bending machine

steel reinforcement stirrup bending machine stirrups bender

stirrups bender  rebar bend and cut factory

rebar bend and cut factory

bar bending machine

bar bending machine  cage welding machine

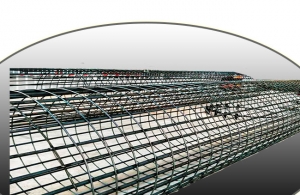

cage welding machine

rebar shear and bending line itech

rebar shear and bending line itech rebar double bending machine

rebar double bending machine rebar shear and bend line

rebar shear and bend line  automatic rebar shear line

automatic rebar shear line

rebar pile cage machine

rebar pile cage machine