The fastest high speed straightening and cutting machine steel wire straightener for mesh welding machine

The fastest high speed wire straightening and cutting machine steel wire straightener for mesh welding machine

High speed reinforcing steel wire straightening and cutting machine,also wire straightener, reinforcement steel wire straightening machine.it is steel rebar processing equipment in cut&bend factory and wire mesh factory. Itech automatic steel wire straightening machine price is not such high as European machine schnell machine or evg machine.itech steel wire rebar straightener machine widely use in cut and bend factory, precast factory, building materials store.We have tnt ring making machine,rebar shear line, stirrup rebar bender, rebar cutting machine ,automatic pile cage making machine,steel wire mesh welding machine…..cut and bend machine.

High speed Wire straightening machine have many unit.like Technical Parameters :mainly divided into 5 parts, such as

1, unloading payoff ;

2, straightening machine;

3, collect bench;

4, electrical System;

- air compressor

- Unloadingpayoff

The payoff includes a base, a discharge tray, tension detection, etc. Bearings are installed between the base and the turntable, so that turntable can rotate flexibly when it is working, and the brake mechanism can adjust the flexibility of the turntable when there is no discharge, so that the parked steel plate will not automatically disperse;

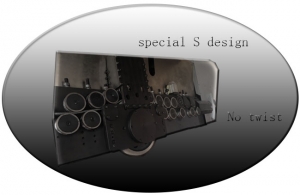

- Straightening machine

Straightening mechanism includes base, frame, feeding wheel and guiding mechanism etc. Straightening wheels include spinner type straightening method.Installed on the slider, adjusting the straightening spinner block to a suitable position can achieve the purpose of straightening the steel bars.cutting motor cutting to length.

- collection bench

The main machine is the wire collect bench part of this wire machine, including measure parts, output line parts, other parts are driven by penuamtic cylinders.c. Upper welded part: Weld the upper end of the upper chord bar and the two oblique bars after wavy bending together. The upper chord bar fine-tuning knob can fine-tune the relative height of the upper chord bar and the oblique bar.

The electrical system includes a high and low voltage power distribution cabinet, an operation console, a pneumatic circuit for discharging and unloading, etc.

- Safety mechanism: It is activated by a button switch to ensure product or personnel damage caused by improper operation by employees. The cooling water of the main engine is completely isolated from the high-voltage power supply, thereby ensuring the safety factor during operation. Danger warning signs are posted in high voltage or dangerous areas of the equipment.

Itech insist provide best service for all customers.As high quality rebar machine supplier China,we want to provide customers more quick and more reliable service.

ITECH stirrup making machine is stable. Automatic stirrup bender, With advanced feeding system,also called anti-twist system. It is feature as shape rebar feeding,servo motor control rebar bending, rebar cutting.It use servo motor as power, extra encoder make accouter, so make tolerance more small and high precision. It can process 6-12mm single wire, 6-10mm double wire, one hour can up 1600 pieces production capacity.

Itech as one professional steel wire/bar processing machinery China supplier,stirrup rebar bending machine, rebar bending machine,cage making machine,,steel wire straightener,truss girder welding machine,lattice girder making machine, steel wire mesh welding machine,rebar shear line,sawing&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.check website http://www.itechbendingmachine.com

wire straightening and cutting machine

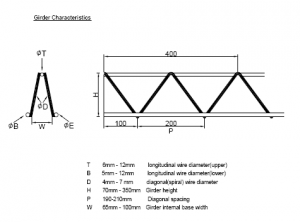

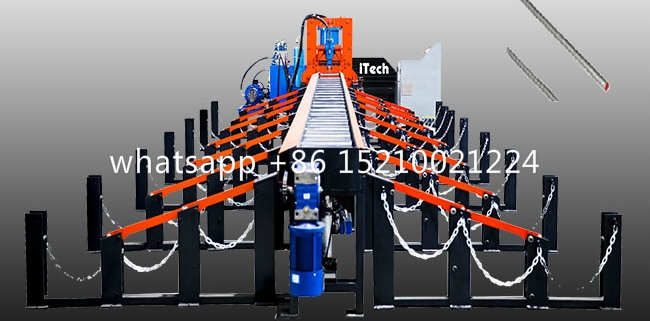

wire straightening and cutting machine truss gieder welding machine truss girder

truss gieder welding machine truss girder

wire mesh machine

wire mesh machine  automatic rebar shear line

automatic rebar shear line

canton fair

canton fair

bar bending machine

bar bending machine

rebar bender

rebar bender

steel bar shaping machine

steel bar shaping machine

saudi big 5

saudi big 5