Reinforcement steel rebar shear line is ready for shipping to South America customer

Reinforcement steel rebar shear line is ready for shipping to South America customer

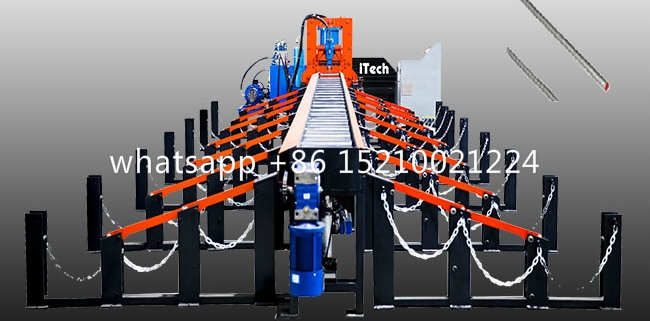

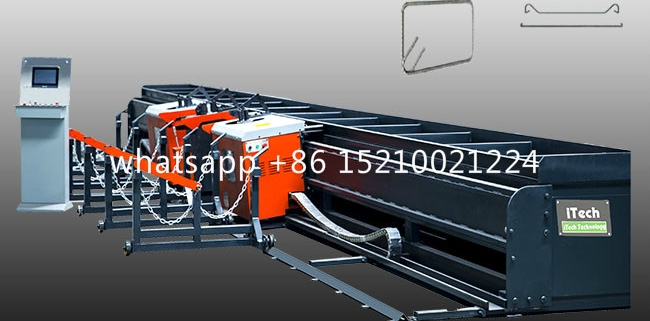

Automatic reinforcement steel rebar shear line is one cut and bend equipment, rebar shear line is for rebar cut to length, rebar cutting process machine in cut and bend factoy.In the construction industry, the use of reinforcement rebar is essential for providing strength and stability to concrete structures. As technology continues to advance, the introduction of automatic reinforcement rebar shear lines has revolutionized the way rebar is processed and cut. This innovative equipment offers a range of benefits, from increased efficiency to improved accuracy, making it a valuable asset for construction projects of all sizes.

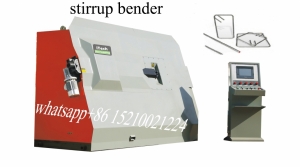

Itech Best selling CNC high quality automatic stirrup bending machine / CNC stirrup bender machine widely use in reinforcement steel wire bar cut and bend factory. Itech as professional reinforcing steel machine supplier. Itech have a series of steel rebar bender machine,like CNC 16mm Stirrup Bending machine,CNC 20mm stirrup bar bending machine , 14mm stirrup wire bending machine and bar shape machine ,automatic rebar pile cage welding machine,cnc automatic pile cage making machine and many kinds of rebar machine. To solve the gap on the stirrups ,Itech stirrup bending machine adopt advanced anti twist feeding system to avoid twist of steel, make stirrup more quick and standard.Shape and bend stirrups effortlessly with our cutting-edge bending machine.

cut&bend factory

One of the key advantages of an automatic reinforcement rebar shear line is its ability to streamline the cutting process. By automating the cutting and processing of rebar, this equipment significantly reduces the time and labor required to prepare reinforcement materials. This not only speeds up the overall construction timeline but also allows for greater productivity and output, ultimately leading to cost savings for construction companies.

In addition to efficiency, automatic reinforcement rebar shear lines also offer enhanced accuracy in the cutting and processing of rebar. The precision and consistency provided by this equipment ensure that each piece of rebar is cut to the exact specifications required for the project. This level of accuracy is crucial for maintaining the structural integrity of concrete structures, ultimately contributing to the safety and longevity of the finished construction.

Furthermore, the use of an automatic reinforcement rebar shear line can lead to a reduction in material waste. With precise cutting and processing capabilities, this equipment minimizes the amount of scrap rebar generated during construction, ultimately leading to cost savings and a more sustainable approach to building. By optimizing the use of materials, construction companies can minimize their environmental impact and contribute to more efficient and responsible construction practices.

Another significant advantage of automatic reinforcement steel rebar shear line is the improvement in worker safety. By automating the cutting and processing of rebar, this equipment reduces the need for manual handling and cutting, minimizing the risk of injuries and accidents on the construction site. This not only creates a safer working environment for construction workers but also helps to mitigate potential liabilities for construction companies.

In conclusion, the introduction of automatic reinforcing rebar shear lines has brought about a range of benefits for the construction industry. From increased efficiency and accuracy to reduced material waste and improved worker safety, this innovative equipment has become an invaluable asset for construction projects. As technology continues to advance, the use of automatic reinforcement rebar shear lines is expected to become increasingly prevalent, further enhancing the way rebar is processed and utilized in construction.

Itech is professional steel wire/bar processing machinery China supplier,stirrup bending machine price , steel rebar bending machine,foundation pile cage making machine,,steel wire straightener,wire straightening and cutting machine, wire mesh welding machine,rebar shear line,rebar sawing&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.

automatic rebar shear line

automatic rebar shear line

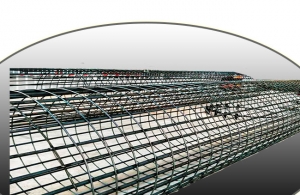

rebar pile cage machine

rebar pile cage machine

stirrups bender

stirrups bender

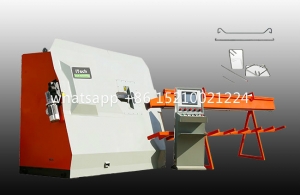

rebar double bender

rebar double bender

wire straightening and cutting machine

wire straightening and cutting machine