CNC automatic cage making machines are a valuable steel machine for drilling company

CNC automatic cage making machines are a valuable steel machine for drilling company

CNC automatic pile cage making machine is important construction equipment in cut and bend factory. In the drilling and manufacturing world, having the right tools and equipment is key to success. A CNC cage making machine is an important piece of machinery that can greatly benefit drilling companies. This advanced technology is designed to streamline the manufacturing process of drilling cages, ultimately helping companies operate more efficiently and effectively.

Itech Best selling CNC high quality automatic stirrup bending machine / CNC stirrup bender machine widely use in reinforcement steel wire bar cut and bend factory. Itech as professional reinforcing steel machine supplier. Itech have a series of steel rebar bender machine,like CNC 16mm Stirrup Bending machine,CNC 20mm stirrup bar bending machine , 14mm stirrup wire bending machine and bar shape machine ,automatic rebar pile cage welding machine,cnc automatic pile cage making machine and many kinds of rebar machine. To solve the gap on the stirrups ,Itech stirrup bending machine adopt advanced anti twist feeding system to avoid twist of steel, make stirrup more quick and standard.Shape and bend stirrups effortlessly with our cutting-edge bending machine.

A CNC cage making machine is a computer-controlled device specifically designed to make cages used in drilling operations. The machine operates through a series of programmed instructions to precisely cut, drill and form metal materials. The result is a high-quality, uniform and precise cage that meets the specific needs of drilling companies.CNC automatic cage making machines are a valuable steel machine for drilling company

One of the main benefits of using a CNC automatic cage making machine is the ability to increase productivity and reduce production time. The machine is able to produce cages at a faster rate than traditional methods, allowing drilling companies to easily meet high demands and deadlines. Additionally, the machine’s accuracy and precision ensure that each cage is of consistent size and quality, eliminating the need for rework and adjustments.

Another key advantage of using a CNC cage pile welding machine is the ability to customize and adjust the design of the cage to meet the drilling company’s unique requirements. Whether it’s a specific size, shape or pattern, the machine can be programmed to produce cages tailored to a company’s exact specifications. This level of customization and flexibility allows drilling companies to meet the diverse needs of customers and projects.

In addition to increasing productivity and customization, CNC cage welding machines help improve the overall safety and reliability of drilling operations. The machine’s precise cutting and drilling capabilities produce cages that are strong, durable and capable of withstanding the rigors of drilling operations. This ultimately helps provide a safer working environment for employees and ensures equipment performs optimally in challenging conditions.

Overall, integrating a CNC pile cage machine into a drilling company’s operations can have a significant impact on its success and efficiency. By simplifying the production process, increasing productivity, and improving the quality of cages, companies can gain a competitive advantage in the industry and better meet customer needs.

CNC cage making machines are a valuable asset to any drilling company looking to enhance their capabilities and products. By investing in this advanced technology, companies can benefit from increased productivity, customization and security, ultimately improving performance and success in the market. As the demand for high-quality and reliable drilling equipment continues to grow, having a CNC cage making machine can help companies stay ahead of the competition and thrive in the industry.

Itech is professional steel wire/bar processing machinery China supplier,stirrup bending machine price , steel rebar bending machine,foundation pile cage making machine,,steel wire straightener,wire straightening and cutting machine, wire mesh welding machine,rebar shear line,rebar sawing&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.

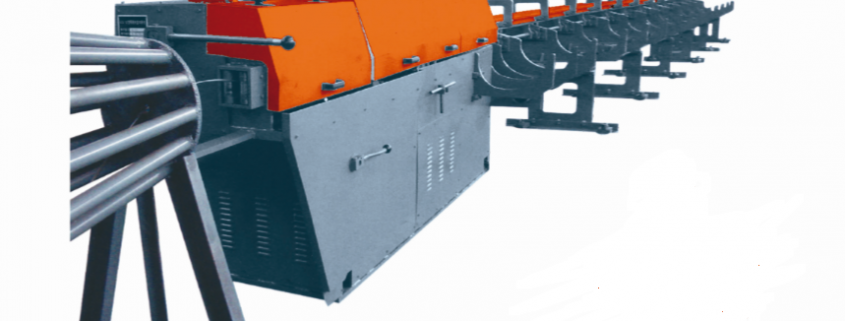

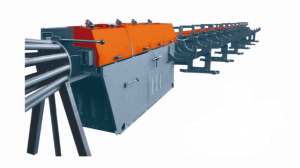

rebar pile cage machine

rebar pile cage machine happy new year 2024

happy new year 2024

high speed straightening machine

high speed straightening machine

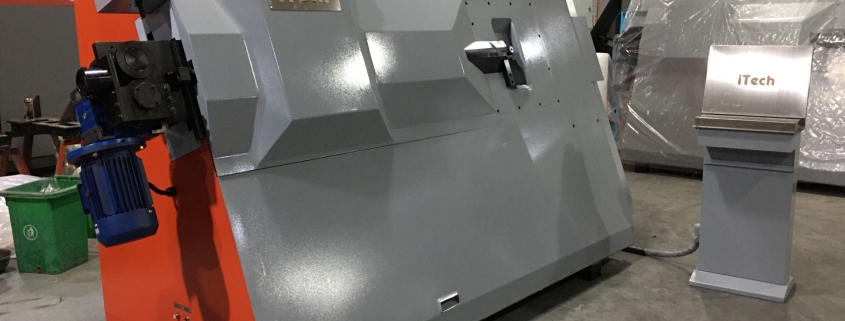

cage welding machine

cage welding machine

steel reinforcement stirrup bending machine

steel reinforcement stirrup bending machine

stirrups bender

stirrups bender