Itech Stirrup Bender Machine Supplier Factory Reopening Dates to Work After Chinese Spring Festival

Itech Stirrup Bender Machine Supplier Factory Reopening Dates to Work After Chinese Spring Festival

The Chinese Spring Festival, also known as the Lunar New Year, is a significant holiday period in China that affects many industries, including manufacturing. For businesses relying on construction machinery such as stirrup bender machines, knowing the factory reopening dates after this holiday is crucial to plan orders and maintain project timelines. As a leading itech stirrup bender machine supplier, understanding their factory reopening schedule and product offerings can help contractors and distributors worldwide stay ahead in their construction projects.

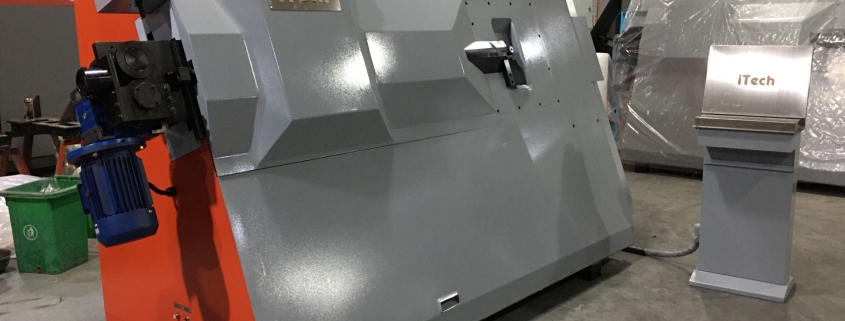

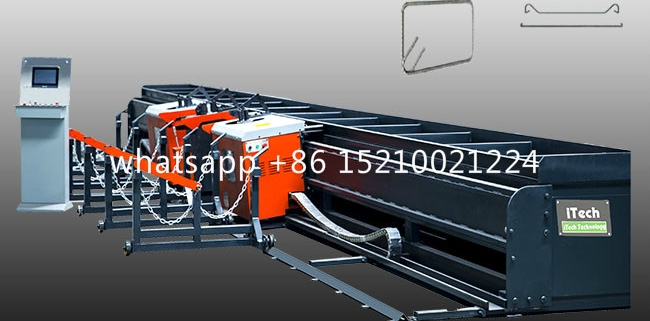

itech as leading steel rebar processing machine supplier, Las Vegas World of Concrete is also opportunity for itech rebar machine. Itech Best selling CNC high quality automatic stirrup bending machine / CNC stirrup bender machine widely use in reinforcement steel wire bar cut and bend factory. Itech as professional reinforcing steel machine supplier. Itech have a series of steel rebar bender machine,like CNC 16mm Stirrup Bending machine,CNC 20mm stirrup bar bending machine , 14mm stirrup wire bending machine and bar shape machine ,automatic rebar pile cage welding machine,cnc automatic pile cage making machine , automatic truss lattice girder welding machine and many kinds of rebar machine. To solve the gap on the stirrups ,Itech stirrup bending machine adopt advanced anti twist feeding system to avoid twist of steel, make stirrup more quick and standard.Shape and bend stirrups effortlessly with our cutting-edge bending machine.

What is the Itech Stirrup Bender Machine?

The itech stirrup bender machine is a specialized piece of construction machinery designed to bend steel wire bars into stirrups, essential for reinforcing concrete structures. These machines are widely used in construction industries globally due to their precision, efficiency, and durability.

Key Features:

High-quality components such as top quality servo systems and encoder systems for durability.

Ability to produce long stirrups and complex shapes.

Automation that reduces manual labor and improves bending accuracy.

Suitable for various diameters of steel bars, typically ranging from 6mm to 16mm or more.

Importance of Factory Reopening Dates After the Chinese Spring Festival

China’s Spring Festival is the longest and most important public holiday, during which most factories, including itech’s, temporarily close. This closure can last from one to three weeks, depending on the company and region. Knowing the reopening dates is vital for:

Supply Chain Planning: Ensures timely ordering of stirrup bending machines and spare parts.

Project Scheduling: Helps construction companies avoid delays by aligning machine deliveries with project timelines.

Customer Support: Enables customers to anticipate when technical support and after-sales services will resume.

According to itech, their factory typically reopens shortly after the Spring Festival, resuming full production and 24/7 customer service to meet global demand. For precise reopening dates, customers are encouraged to contact itech directly via their official communication channels, such as WhatsApp (+86 15210021224) or their website itechbendingmachine.com.

Why Choose Itech as Your Stirrup Bender Machine Supplier?

Itech stands out in the competitive market of steel wire bar processing machinery due to several advantages:

Professional Team: With engineers boasting over five years of experience, itech ensures expert solutions for all customer needs.

Quality Assurance: 100% inspection during production and before delivery guarantees high-quality machines.

Fast Response: Customer inquiries receive feedback within 12 hours, ensuring efficient communication.

Comprehensive Product Range: From stirrup benders and rebar cutting machines to wire mesh welding machines and cage making machines, itech offers a full suite of construction machinery.

Global Reach: Serving markets in North America, Europe, the Middle East, Southeast Asia, and more.

Tips for Ordering and Working with Itech Post-Spring Festival

Plan Ahead: Place orders before the Spring Festival to avoid delays caused by factory closure.

Confirm Reopening Dates: Reach out to itech’s sales team to get the latest updates on reopening schedules.

Request After-Sales Support: Ensure your team is aware of the 24/7 support available once the factory resumes operations.

Explore Product Updates: Itech regularly updates its machines to improve efficiency, such as the recent enhancements in automatic stirrup bender machines for European customers.

Conclusion

For construction professionals seeking reliable stirrup bender machines, partnering with a trusted supplier like itech is essential. Understanding the factory reopening dates after the Chinese Spring Festival allows businesses to plan effectively, avoid project delays, and maintain a steady supply of high-quality machinery. Stay connected with itech for timely updates, superior products, and dedicated support to enhance your construction operations.

Ready to boost your project efficiency with itech stirrup bender machines? Visit itechbendingmachine.com or contact their team today via WhatsApp at +86 15210021224 to learn more about reopening schedules and product availability.

stirrup bender

stirrup bender  stirrup bending machine

stirrup bending machine rebar double bender

rebar double bender

rebar bender

rebar bender

spiral making machine

spiral making machine

steel reinforcement stirrup bending machine

steel reinforcement stirrup bending machine

stirrups bender

stirrups bender