Celebrating China’s National Holiday and Mid-Autumn Festival with Itech Rebar Processing Machines

Itech Rebar Processing Machines supplier celebrate China’s National Holiday and Mid-Autumn Festival

Itech Rebar Processing Machines supplier celebrate China’s National Holiday and Mid-Autumn Festival. As China gears up to celebrate its National Holiday and the Mid-Autumn Festival, it’s a time of joy, reflection, and unity. Amidst the festivities, industries across the nation also take a moment to appreciate the technological advancements that drive their success. One such innovation is the Itech Rebar Processing Machine, a marvel in construction technology that has revolutionized the sector.

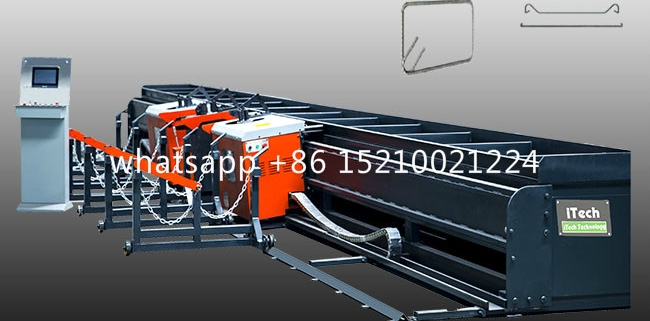

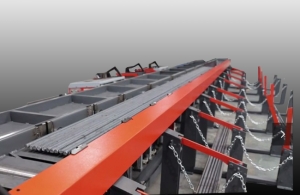

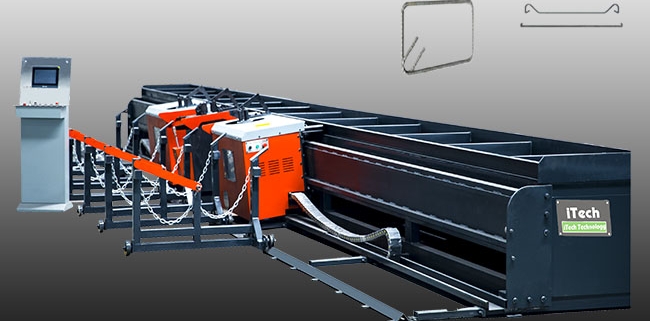

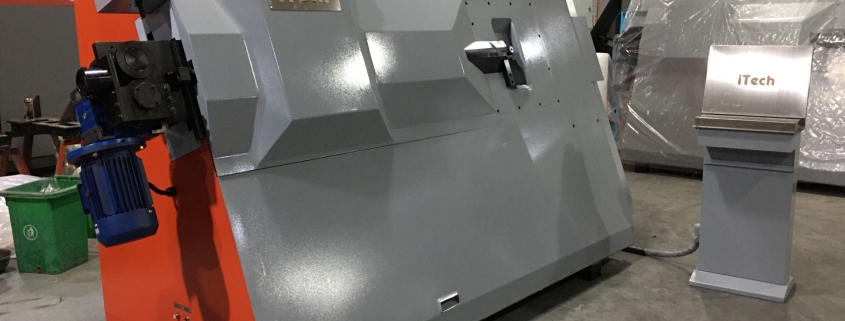

itech Best selling CNC high quality automatic stirrup bending machine / CNC stirrup bender machine widely use in reinforcement steel wire bar cut and bend factory. Itech as professional reinforcing steel machine supplier. Itech have a series of steel rebar bender machine,like CNC 16mm Stirrup Bending machine,CNC 20mm stirrup bar bending machine , 14mm stirrup wire bending machine and bar shape machine ,automatic rebar pile cage welding machine,cnc automatic pile cage making machine , automatic truss lattice girder welding machine and many kinds of rebar machine. To solve the gap on the stirrups ,Itech stirrup bending machine adopt advanced anti twist feeding system to avoid twist of steel, make stirrup more quick and standard.Shape and bend stirrups effortlessly with our cutting-edge bending machine.

The Significance of Itech Rebar Processing Machines

Itech Rebar Processing Machines have become a cornerstone in the construction industry, known for their precision and efficiency. These machines are designed to handle the intricate task of rebar threading, a critical process in construction projects. With the increasing demand for high-quality infrastructure, the importance of reliable rebar processing cannot be overstated.

Key Features of Itech Rebar Processing Machines

Precision Engineering: Itech machines are renowned for their high precision, ensuring that each rebar is processed to exact specifications.

Durability: Built to withstand rigorous use, these machines offer longevity and consistent performance.

Automation: With options for semi-automatic and fully automatic machines, Itech provides flexibility to meet various project needs.

Celebrating Technological Advancements

As we celebrate the National Holiday and Mid-Autumn Festival, it’s essential to acknowledge the technological advancements that contribute to our nation’s progress. The Itech Rebar Processing Machine is a testament to China’s commitment to innovation and excellence in the construction industry.

Benefits of Using Itech Rebar Processing Machines

Increased Efficiency: Automation reduces manual labor, speeding up the construction process.

Cost-Effective: Minimizing errors and waste, these machines help in reducing overall project costs.

High-Quality Output: Consistent and precise threading ensures the structural integrity of construction projects.

Insights from Industry Leaders

According to a report from Today’s Machining World, the demand for high-end precision rebar threading machines is on the rise. This trend underscores the importance of investing in reliable and advanced machinery like the Itech Rebar Processing Machine.

Embracing the Future

The integration of cutting-edge technology in rebar processing is not just about meeting current demands but also about preparing for the future. With continuous advancements, machines like those from Itech are paving the way for smarter, more efficient construction practices.

Why Choose Itech?

Reputation for Excellence: Itech is a trusted name in the industry, known for delivering high-quality machines.

Customer Support: Comprehensive support and warranty services ensure customer satisfaction and peace of mind.

Innovation: Constant updates and improvements keep Itech machines at the forefront of technology.

Conclusion

As we celebrate the dual festivities of China’s National Holiday and the Mid-Autumn Festival, let us also celebrate the technological advancements that drive our industries forward. The Itech Rebar Processing Machine stands as a symbol of innovation, efficiency, and quality in the construction sector.

For those in the industry, now is the perfect time to invest in technology that promises to enhance productivity and quality. Explore the possibilities with Itech and ensure your projects are built on a foundation of excellence.

Call to Action: Discover more about Itech Rebar Processing Machines and how they can transform your construction projects. Visit itech website for more information and take the first step towards innovation today.

stirrup bender rebar double bender shear line mesh machine pile cage machine wire mesh machine

cut and bend

cut and bend truss gieder welding machine truss girder

truss gieder welding machine truss girder rebar sawing and threading line

rebar sawing and threading line Concrete Show South East Asia - itech rebar cut and bend machine China manufacture & supplier

Concrete Show South East Asia - itech rebar cut and bend machine China manufacture & supplier rebar double bender

rebar double bender

concrete show south america

concrete show south america rebar bender

rebar bender  double bending machine

double bending machine pile cage machine

pile cage machine

rebar bend and cut factory

rebar bend and cut factory