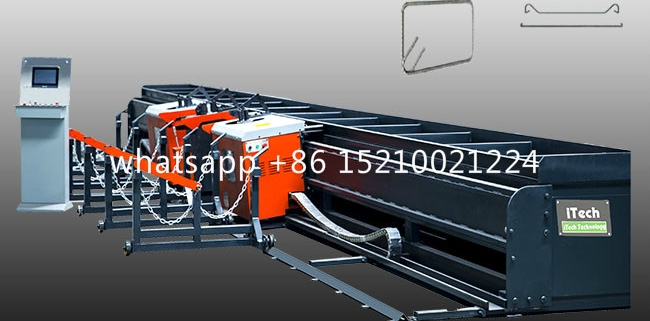

Precast Concrete Equipment Lattice Girder Welding Machines in reinforcement steel rebar cut and bend factory

Precast Concrete Equipment Lattice Girder Welding Machines in reinforcement steel rebar cut and bend factory

In the world of construction,precast become trend more and more than before. One innovation that stands out in the precast concrete industry is the lattice girder welding machine. It is widely used rebar machines in rebar cut and bend plant, concrete precast factory,infrastructure construction company, pile drilling company, building materials factory or store.This equipment is essential for producing lattice girders, which play a crucial role in enhancing the structural integrity of prefabricated slabs. In this article, we’ll delve into the significance of precast concrete equipment, specifically lattice girder welding machines, and explore their benefits and functionalities.

itech Best selling CNC high quality automatic stirrup bending machine / CNC stirrup bender machine widely use in reinforcement steel wire bar cut and bend factory. Itech as professional reinforcing steel machine supplier. Itech have a series of steel rebar bender machine,like CNC 16mm Stirrup Bending machine,CNC 20mm stirrup bar bending machine , 14mm stirrup wire bending machine and bar shape machine ,automatic rebar pile cage welding machine,cnc automatic pile cage making machine , automatic truss lattice girder welding machine and many kinds of rebar machine. To solve the gap on the stirrups ,Itech stirrup bending machine adopt advanced anti twist feeding system to avoid twist of steel, make stirrup more quick and standard.Shape and bend stirrups effortlessly with our cutting-edge bending machine.

Automatic Truss girder welding machine Key Features and Benefits

Automated Production: The truss girder welding machines offer fully automatic height and diameter adjustments during production. This automation allows for precise manufacturing without the need for time-consuming retrofitting.

Flexibility and Customization: These machines can adjust the distance between spot welds on diagonal wires, ensuring accurate cutting and customization according to specific project requirements.

High Output and Cost-Effectiveness: itech machine fully automatic lattice girder welding machines provide reliable and cost-effective production solutions. Their powered de-coiling stations and wire tension sensors ensure precise wire feeding, enhancing output efficiency.

User-Friendly Operation: Equipped with user-friendly software, these machines require minimal programming skills. This feature is particularly beneficial for operators, allowing them to supervise the production process with ease.

Precast Concrete Equipment Lattice Girder Welding Machines in reinforcement steel rebar cut and bend factory

Remote Access and Maintenance: itech machines offer remote access via an internet connection for troubleshooting and routine maintenance, ensuring uninterrupted production and reducing downtime.

Types of Lattice Girder Welding Machines

Several types diverse models of lattice girder welding machines, catering to various production needs:

Integrated steel truss machine: automated solutions, complete design machines configured for producing lattice girders, eliminating changeover ties through automatic height change.

Modular steel truss machine: Offers a wide range of lattice girder processing solutions, machine have different unit: including machines for cutting, welding, and storing lattice girders.

Thoes series includes sustainable solutions for automatic mesh welding and reinforcing steel processing, suitable for high-output production.

Truss lattice girder welding machine Applications in Precast Concrete Industry

Lattice girders serve two primary purposes in the precast concrete industry:

Structural Reinforcement: They secure the bond between prefabricated slabs and cast-in-situ concrete, ensuring the load-bearing capacity of the installed slabs.

Spacers for Mesh: Used as spacers between mesh, ceiling, and wall elements, lattice girders maintain precise spacing and contribute to the structural integrity of concrete components.

Conclusion

Lattice girder welding machines are indispensable in the precast concrete industry, offering automated, flexible, and cost-effective manufacturing solutions. Their ability to produce high-quality lattice girders efficiently makes them a valuable asset for construction projects worldwide. As technology advances, these machines continue to evolve, providing even greater precision and reliability. For those involved in precast concrete production, investing in state-of-the-art lattice girder welding machines is a step towards enhancing productivity and ensuring the success of construction projects.

Call to Action: Explore the latest advancements in lattice girder welding machines and discover how they can revolutionize your precast concrete production. Visit itech for more information on cutting-edge equipment that can elevate your construction projects.

Itech is professional steel wire/bar processing machinery China supplier,stirrup bending machine price , steel rebar bending machine,foundation pile cage making machine,,steel wire straightener,wire straightening and cutting machine, wire mesh welding machine,rebar shear line,rebar sawing&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.

truss gieder welding machine truss girder

truss gieder welding machine truss girder rebar sawing and threading line

rebar sawing and threading line Concrete Show South East Asia - itech rebar cut and bend machine China manufacture & supplier

Concrete Show South East Asia - itech rebar cut and bend machine China manufacture & supplier rebar double bender

rebar double bender