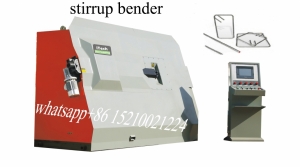

Reinforcement steel rebar anti twist stirrup bender is important tools for steel rebar processing machine in reinforcing steel cut and bend factory

Reinforcement steel rebar anti twist stirrup bender is important tools for steel rebar processing machine in reinforcing steel cut and bend factory

In the field of construction and infrastructure development, steel plays a vital role in providing necessary strength and support to various structures. Steel bars are widely used in the construction industry and often need to be process in steel cut and bend plant. This is where anti-twist stirrup bending machines come into play, especially for steel rebar cutting machine and rebar bending machine in plants.

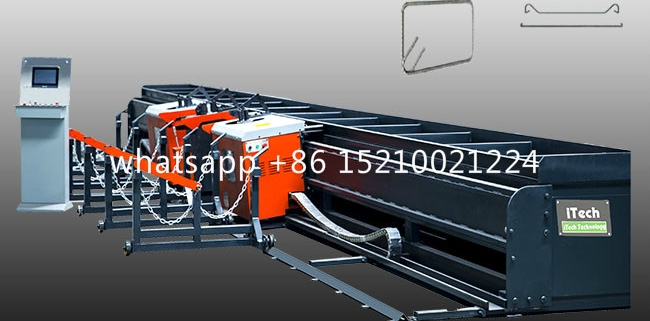

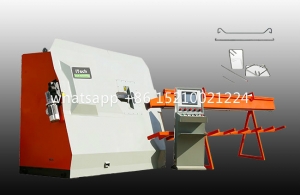

Itech Best selling CNC high quality automatic stirrup bending machine / CNC stirrup bender machine widely use in reinforcement steel wire bar cut and bend factory. Itech as professional reinforcing steel machine supplier. Itech have a series of steel rebar bender machine,like CNC 16mm Stirrup Bending machine,CNC 20mm stirrup bar bending machine , 14mm stirrup wire bending machine and bar shape machine ,automatic rebar pile cage welding machine,cnc automatic pile cage making machine and many kinds of rebar machine. To solve the gap on the stirrups ,Itech stirrup bending machine adopt advanced anti twist feeding system to avoid twist of steel, make stirrup more quick and standard.Shape and bend stirrups effortlessly with our cutting-edge bending machine.

anti-twist stirrup bender machine is a rebar machine specially designed to bend steel bars into various shapes, with a special focus on the production of stirrups making. Rebar steel Stirrups are an important part of reinforcement concrete structures, providing necessary support and stability to the concrete. These reinforcement stirrups need to be precisely bent and rebar forming to ensure the structural integrity of the final structure.

One of the main advantages of used anti-twist stirrup bending machine in steel cut and bend plants is its ability to produce reinforcement stirrups with minimal to no twist. This is critical because twisted stirrups can compromise the structural strength of the concrete, leading to potential safety hazards. By using anti-torsion stirrup bending machines, steel cutting and bending factories can ensure that the stirrups produced meet the required standards and specifications without any twisting, thus improving the overall quality of the construction materials.

Furthermore, the use of anti-twist stirrup bending machines in steel cutting and steel bending plants can significantly increase the efficiency and productivity of the bending process. Equipped with advanced technology and automation features, these machines are able to bend steel bars quickly and accurately, reducing the time and labor required for manual bending. This not only increases factory throughput but also ensures consistent and precise bending results, resulting in higher quality products.

Additionally, automatic stirrup bending machines are designed to handle various sizes and diameters of steel bars, making them versatile and adaptable to various project requirements. Whether producing standard stirrups or custom-shaped bars, these machines can meet different bending needs, giving steel cutting and bending shops the flexibility to meet different customer needs.

In terms of safety, using anti-twist stirrup bending machines in steel cutting and bending plants can minimize the risk of workplace accidents associated with the manual bending process. By automating bending operations, workers can reduce potential hazards such as repetitive strain injuries or accidents caused by handling heavy rebar. Not only does this create a safer working environment, it also contributes to the overall well-being of factory employees.

In summary, Reinforcement steel rebar anti twist stirrup bender, the integration of anti-twist stirrup bending machines in steel cutting and bending plants helps improve the efficiency, quality and safety of the steel bending process. These machines play a vital role in producing precisely shaped stirrups and other steel components, ensuring the construction industry gets high-quality materials to build durable and resilient structures. As the demand for steel bars continues to grow, the importance of torsion stirrup bending machines in steel cutting and bending plants cannot be underestimated, making them an indispensable asset in the construction supply chain.

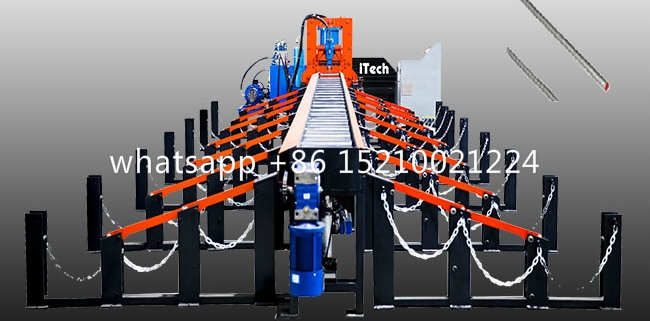

Itech is professional steel wire/bar processing machinery China supplier,stirrup bending machine price , steel rebar bending machine,foundation pile cage making machine,,steel wire straightener,wire straightening and cutting machine, wire mesh welding machine,rebar shear line,rebar sawing&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.

stirrups bender

stirrups bender  automatic rebar shear line

automatic rebar shear line

rebar double bender

rebar double bender

wire straightening and cutting machine

wire straightening and cutting machine

rebar pile cage machine

rebar pile cage machine

happy new year 2024

happy new year 2024