Rebar Stirrup Bender Machine maintenance and trouble shooting : How to Reset the Zero Position

Rebar Stirrup Bender Machine maintenance and trouble shooting : Zero Position Comprehensive Guide

In the rebar processing work and construction, precision is paramount. Rebar stirrup bender machines play a crucial role in shaping steel bars into specific angles and forms. However, one common issue that operators face is the machine resetting to zero unexpectedly. Understanding how to reset the rebar stirrup bender machine zero position is essential for maintaining efficiency and accuracy in your work. This guide will walk you through the steps to troubleshoot and fix this issue, ensuring your machine operates smoothly.

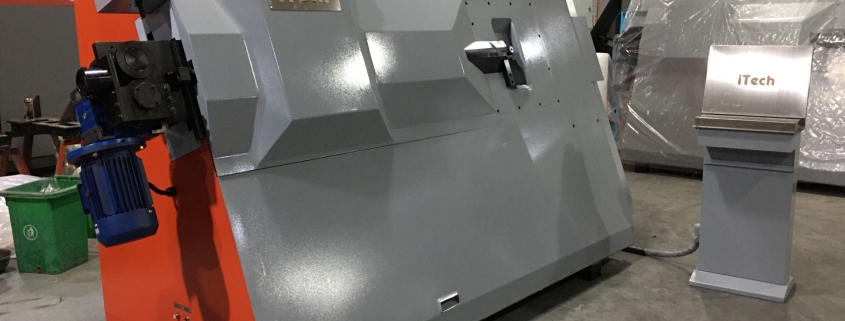

itech Best selling CNC high quality automatic stirrup bending machine / CNC stirrup bender machine widely use in reinforcement steel wire bar cut and bend factory. Itech as professional reinforcing steel machine supplier. Itech have a series of steel rebar bender machine,like CNC 16mm Stirrup Bending machine,CNC 20mm stirrup bar bending machine , 14mm stirrup wire bending machine and bar shape machine ,automatic rebar pile cage welding machine,cnc automatic pile cage making machine and many kinds of rebar machine. To solve the gap on the stirrups ,Itech stirrup bending machine adopt advanced anti twist feeding system to avoid twist of steel, make stirrup more quick and standard.Shape and bend stirrups effortlessly with our cutting-edge bending machine.

Understanding the cut and bend factory equipment Rebar Stirrup Bender Machine

Before diving into the reset process, it’s important to understand how a rebar stirrup bender machine functions. These machines are designed to bend steel bars into various shapes and sizes, typically using hydraulic or mechanical systems. The zero position is a reference point that the machine uses to ensure precise bending angles. When this position is lost, it can lead to inaccurate bends and disrupted workflows.

Common Causes of Zero Position Reset

Several factors can cause a rebar stirrup bender machine to reset to zero:

Software Glitches: Like any computerized equipment, software glitches can cause the machine to lose its zero position.

Sensor Malfunctions: Faulty sensors may fail to detect the correct position, leading to resets.

Mechanical Issues: Wear and tear on mechanical components can disrupt the machine’s ability to maintain its zero position.

Replace rebar stirrup bending machine spare parts Problems: when replace spare parts interfere with position settings.

User Errors: Incorrect operation or input errors by the operator can also lead to this issue.

Rebar Stirrup Bender Machine maintenance and trouble shooting : How to Reset the Zero Position

Preparation and Safety Measures

Turn Off the Machine: Ensure rebar bender machine is powered off and disconnected from the power source.

Wear Safety Gear: Equip yourself with safety gloves and glasses to protect against electrical hazards and mechanical components.

Consult the Manual: Refer to reinforcement cut and bend machine manual for model-specific instructions.

Troubleshooting Steps

Addressing Software Glitches

Restart the Machine: Power off and restart reinforcing steel fabrication machine to clear temporary glitches.

Update Software: Check for software updates from itech and install them.

Factory Reset: As a last resort, find the system setting, press zero search zero button.

Check Sensor Connections: Ensure all sensor connections are secure and undamaged.

Test Sensors: Use a multimeter to check sensor functionality and replace any faulty ones.

Resolving Mechanical and Electrical Issues

Inspect Mechanical Parts: Look for wear on gears, levers, and linkages. Lubricate and replace as necessary.

Check Wiring: Inspect wiring for damage and ensure connections are tight.

Test Control Panel: Use a multimeter to verify proper voltage and operation.

Avoiding User Errors

Operator Training: Ensure operators are properly trained on machine use.

Verify Inputs: Double-check all input parameters before starting the bending process.

Testing and Calibration

Perform a Test Bend: After troubleshooting, conduct a test bend to verify stability.

Calibrate the Machine: Recalibrate angle settings as per the manufacturer’s instructions.

Monitor Performance: Continuously observe the machine to ensure the issue is resolved.

Conclusion

Resetting the zero position on a automatic rebar stirrup bending machine is essential for maintaining precision and efficiency in metalworking tasks. By following the troubleshooting steps outlined in this guide, you can diagnose and fix common issues, ensuring your machine operates smoothly. Regular maintenance and proper operation are key to preventing future problems. For more detailed instructions, always refer to your machine’s manual and consult with the manufacturer if necessary.

Call to Action

If you found this guide helpful, share it with your colleagues and explore more resources on maintaining and troubleshooting metalworking machinery. Stay informed and keep your operations running smoothly!

Itech is professional steel wire/bar processing machinery China supplier,stirrup bending machine price , steel rebar bending machine,foundation pile cage making machine,,steel wire straightener,wire straightening and cutting machine, wire mesh welding machine,rebar shear line,rebar sawing&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.

wire straightening and cutting machine

wire straightening and cutting machine rebar bender

rebar bender

Leave a Reply

Want to join the discussion?Feel free to contribute!