Mastering Automatic Stirrup Bender Machines Maintenance and Troubleshooting : rebar feeding servo alarm

Mastering Automatic Stirrup Bender Machines Maintenance and Troubleshooting : rebar feeding servo alarm

In the developping world of construction, automatic rebar machine is one trend. The automatic rebar stirrup bender machine, a vital piece of equipment in reinforcement steel cut and bend factory,precast factory and construction company, offers a high efficiency rebar bending and cuting process,improve production capacity. However, like all machinery, it requires regular maintenance and troubleshooting to function optimally. This article delves into the essential aspects of maintaining and troubleshooting automatic rebar stirrup bender machines, ensuring they continue to perform flawlessly.

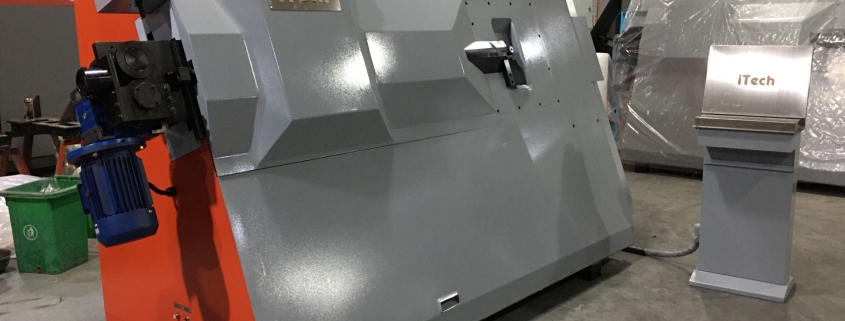

itech Best selling CNC high quality automatic stirrup bending machine / CNC stirrup bender machine widely use in reinforcement steel wire bar cut and bend factory. Itech as professional reinforcing steel machine supplier. Itech have a series of steel rebar bender machine,like CNC 16mm Stirrup Bending machine,CNC 20mm stirrup bar bending machine , 14mm stirrup wire bending machine and bar shape machine ,automatic rebar pile cage welding machine,cnc automatic pile cage making machine and many kinds of rebar machine. To solve the gap on the stirrups ,Itech stirrup bending machine adopt advanced anti twist feeding system to avoid twist of steel, make stirrup more quick and standard.Shape and bend stirrups effortlessly with our cutting-edge bending machine.

Understanding the Automatic reinforcing steel wire Stirrup Bending Machine

Automatic stirrup bending machines made of by rebar wire feeding servo, rebar bending servo and cutting system. The all system use anti twist system, so avoid wire twist when wire feeding. After rebar feeding, then rebar bender machine finish bending process according to the shapes on touch screen. Rebar bending machine cutting by fix balde and movable blades. Servo system is the most important parts for rebar bending machine. Automatic stirrup bender servo Maintenance and Troubleshooting is important job for maintenance people. Regular Maintenance Practices

Common Troubleshooting Techniques

Despite regular maintenance, issues may still arise. Here are some common problems and their solutions:

Machine Won’t Start:

Possible Causes: Power failure, loose power line, or faulty power button.

Solutions: Check the power supply, tighten any loose connections, and replace the power button if necessary.

Inaccurate Bending Angles:

Possible Causes: Incorrect parameter settings or misaligned clamping device.

Solutions: Reassess and adjust the parameters, ensuring the clamping device is correctly aligned.

Unstable Operation:

Possible Causes: Lack of maintenance, excessive friction, or loose protective covers.

Solutions: Conduct regular maintenance, lubricate moving parts, and secure all protective covers.

Motor Reversion:

Possible Causes: Jammed bending arm or loose angle adjuster clips.

Solutions: Adjust the bending arm and secure the adjuster clips.

Mastering Automatic Stirrup Bender Machines Maintenance and Troubleshooting : rebar feeding servo alarm error 731

Bending servo 731 alarm happend when the bending servo wire remove and wire break. So when have alarm 731, first step is check the wire connection. After connect well wire cables, need operate on the servo panel.

- Press set

- Press mode

- Press up arrow until find D

- Press set

- Press right arrow

- Press up arrow and change 0 to 2

- Press set

- Press up arrow,make 0 to 1

- Press set 5 seconds

The automatic rebar stirrup bender machine is an indispensable tool in construction, offering unmatched efficiency and precision. By adhering to regular maintenance schedules and employing effective troubleshooting techniques, you can ensure its longevity and optimal performance. For further insights, consider exploring expert resources and engaging with industry webinars to stay updated on best practices. Remember, a well-maintained machine is not only a cost-effective investment but also a cornerstone of successful construction projects.

Call to Action: For more detailed maintenance tips and troubleshooting guides, subscribe to industry webinars or consult with itech rebar machinery experts. Share this article with your colleagues to promote best practices in rebar stirrup bender machine maintenance.

Itech is professional steel wire/bar processing machinery China supplier,stirrup bending machine price , steel rebar bending machine,foundation pile cage making machine,,steel wire straightener,wire straightening and cutting machine, wire mesh welding machine,rebar shear line,rebar sawing&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.

rebar bend and cut factory

rebar bend and cut factory  pile cage machine

pile cage machine

Leave a Reply

Want to join the discussion?Feel free to contribute!