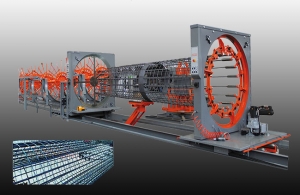

2022 high quality rebar pile cage making machine price China supplier

2022 high quality rebar pile cage making machine price China supplier

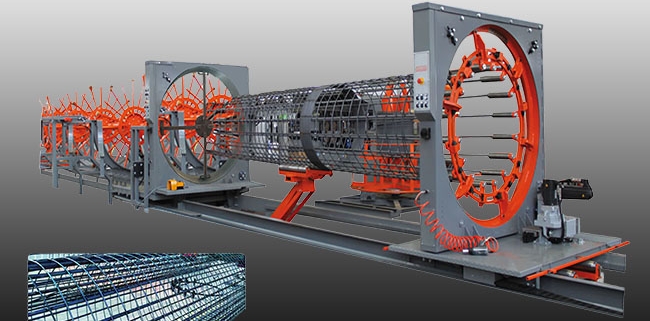

2022 high quality cage making machine price China supplier. As one professional steel wire bar processing machine supplier ,Itech provide high quality anti-twist rebar stirrup bending machine ,rebar pile cage making machine in production line.it have more aadvantage than common manual rebar pile cage welding machine.

Rebar pile cage making machine operate manual

1) Feeding: Put the main rebar on the support manually or with a crane, then start the automatic feeding device, put the main steel reinforcement into the distribution rack, and use the crane to place the coiled steel wire on the discharge rack;

2) Fix the main rebar through the main rebar: Pass the main rebar through the template hole on the fixed rotating plate, and then pass through the template hole on the mobile rotating plate, and fix the main rib as required by the clamp on the mobile template;

cut&bend factory

3) Fixed stirrups: Pass the stirrups through the straightening device, and then weld them on the main reinforcement;

4) Start welding and forming: the reinforcing bar pile cage is welded and formed, the main bar rotates with the rotating disc, and at the same time, the moving rotary disc is clamped and dragged to move forward; at this time, the winding bar is also automatically wound on the main bar; The speed ratio between rotation and forward movement is realized;

5) Walking welding and support lifting: the rotating disc drives the main rib to rotate and walk forward, the winding rib is wound with the main rib, and the winding rib is manually spot welded on the main rib while walking. After reaching a certain distance, the first support is lifted up to support the steel cage to prevent the steel cage from sagging due to its own weight, and then keep walking forward, and the support behind is gradually lifted;

6) Welding is completed: when the moving rotating disk drives the semi-finished steel cage to move away from the fixed disk, the welding is terminated, the winding bars are cut off, and the steel cage continues to move forward under the driving of the moving rotating disk and is separated from the fixed rotating disk. After the end leaves the working platform of the fixed turntable, it stops, and then loosens the bolts that fix the main bars on the moving turntable, the moving turntable continues to move forward, and the reinforcement cage is released from the moving turntable;

7) Unloading the pile cage from cage making machine: After the steel cage is separated from the moving rotating disk, the supports are lowered together smoothly, and then the steel cage is lifted out (or rolled out from the support);

Mobile disc return: After the steel cage is hoisted away, the mobile disc is reset and enters the next cycle of production

Itech as one professional steel wire/bar processing machinery China supplier,Stirrup Bending machine,CNC stirrup bar bending machine,stirrup wire bending machine and bar shape machine,rebar pile cage making machine,,samll pile cage welding machine, steel wire straightener, wire mesh welding machine,rebar shear line,sawing&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.

pile cage making machine

pile cage making machine

itech

itech

Leave a Reply

Want to join the discussion?Feel free to contribute!