What’s Different: Steel Bar Stirrup Bender and Rebar Double Bender

What’s Different: Steel Bar Stirrup Bender and Rebar Double Bender

In the world of infrastructure construction, reinforcement fabricate cut&bend and precast concrete projects, understanding What’s Different: Steel Bar Stirrup Bender and Rebar Double Bender, that facilitate efficient work is crucial. bar stirrup bender and the rebar double bender, each serving a unique purpose in shaping steel bars. But what’s different between these two machines? This article delves into their distinctions, functionalities, and applications, providing insights that can help you choose the right tool for your project.

Itech Best selling CNC high quality automatic stirrup bending machine / CNC stirrup bender machine widely use in reinforcement steel wire bar cut and bend factory. Itech as professional reinforcing steel machine supplier. Itech have a series of steel rebar bender machine,like CNC 16mm Stirrup Bending machine,CNC 20mm stirrup bar bending machine , 14mm stirrup wire bending machine and bar shape machine ,automatic rebar pile cage welding machine,cnc automatic pile cage making machine and many kinds of rebar machine. To solve the gap on the stirrups ,Itech stirrup bending machine adopt advanced anti twist feeding system to avoid twist of steel, make stirrup more quick and standard.Shape and bend stirrups effortlessly with our cutting-edge bending machine.

Understanding Bar Stirrup Benders,What is a Bar Stirrup Bender?

A bar stirrup bender is a specialized machine used to bend steel reinforcing steel bar into various shapes, automatic stirrup bender is primarily for creating stirrups. Stirrups are closed loops of reinforcement bars that hold the main reinforcement bars together in concrete elements. These machines are essential for preventing buckling and resisting lateral loads in columns and beams.

Types of Bar Stirrup Benders

Manual Stirrup Bender: Operated manually without electricity, ideal for small-scale projects. It is labor-intensive but offers high productivity on-site.

Bar shaping Bender Machine: Powered by electricity, it can bend multiple bars simultaneously but requires pre-cut bars.

Hydraulic iron bar forming machine: Uses hydraulic systems for power, offering faster bending with adjustable angles.

Automatic CNC Stirrup rebar Bender: Controlled by computer numerical systems for precise bending, suitable for bulk production.

Exploring Rebar Double Benders,What is a Rebar Double Bender?

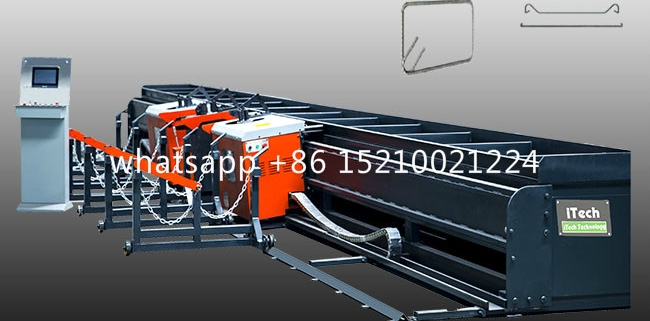

The rebar double bender is designed for processing larger steel bars, typically used in infrastructure projects like bridges and large columns. It can bend steel bars of various diameters, making it versatile for different construction needs.

Types of Rebar Double Benders

Worm Screw Reinforcing Rebar Bender: Utilizes a worm gear system for precise bending.

Gear-Type Reinforcing Rebar Bender: Features automatic angle control and braking devices for efficient bending.

Automatic Rebar double bending Machine: two rebar bender head, can work together, improve bar bending speed and capacity.

Key Differences Between Stirrup Benders and Rebar Double Benders

Purpose: Stirrup benders are primarily for creating stirrups, while double benders handle larger bars for broader applications.

Capacity: Stirrup benders generally process smaller diameters, whereas double benders accommodate larger diameters.

Automation: CNC stirrup benders offer higher automation compared to manual and semi-automatic double benders. Automatic Rebar double bender also have automatic modes.

Stirrup benders Price and rebar double bender: automatic double bender are typically more affordable than stirrup benders due to their specific use and smaller capacity.

Conclusion

Choosing between a bar stirrup bender and a rebar double bender depends on your project’s requirements. For stirrup production in reinforced concrete, a stirrup bender is indispensable and usually up to 32mm steel bar. Meanwhile, for larger infrastructure projects, a double bender offers the capacity needed for robust construction and usually up to 40mm or 50mm. Understanding these differences ensures efficient and cost-effective operations in your construction endeavors.

Call to Action: Explore our range of stirrup and rebar benders to find the perfect fit for your project needs. Visit our website for more information and expert advice on choosing the right machine.

Itech is professional steel wire/bar processing machinery China supplier,stirrup bending machine price , steel rebar bending machine,foundation pile cage making machine,,steel wire straightener,wire straightening and cutting machine, wire mesh welding machine,rebar shear line,rebar sawing&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.

rebar double bender

rebar double bender

rebar bender

rebar bender  wire straightening and cutting machine

wire straightening and cutting machine

Leave a Reply

Want to join the discussion?Feel free to contribute!