8-16mm Automatic Stirrup Bending Machine for Coil in Cut and Bend Plant: Revolutionizing rebar bending machine for construction

8-16mm Automatic Stirrup Bending Machine for Coil in Cut and Bend Plant: Revolutionizing rebar bending machine for construction

with construction machinery development, reinforcement steel bending stirrups from steel coil, a task that has been transformed by advanced rebar processing machinery. The 8-16mm automatic stirrup bending machine for coil in cut and bend plant is a game-changer, offering unparalleled productivity, accuracy, and versatility. This article explores the features, advantages, and applications of this essential equipment, drawing insights from leading industry technologies.

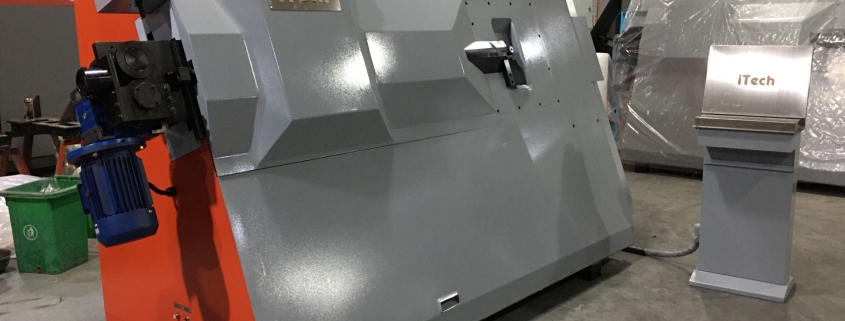

itech Best selling CNC high quality automatic stirrup bending machine / CNC stirrup bender machine widely use in reinforcement steel wire bar cut and bend factory. Itech as professional reinforcing steel machine supplier. Itech have a series of steel rebar bender machine,like CNC 16mm Stirrup Bending machine,CNC 20mm stirrup bar bending machine , 14mm stirrup wire bending machine and bar shape machine ,automatic rebar pile cage welding machine,cnc automatic pile cage making machine , automatic truss lattice girder welding machine and many kinds of rebar machine. To solve the gap on the stirrups ,Itech stirrup bending machine adopt advanced anti twist feeding system to avoid twist of steel, make stirrup more quick and standard.Shape and bend stirrups effortlessly with our cutting-edge bending machine.

What is an 8-16mm Automatic Stirrup Bending Machine?

An automatic stirrup bending machine is a CNC-controlled device designed to straighten, measure, bend, and cut steel bars—specifically rebar—into precise stirrup shapes. The 8-16mm specification refers to the diameter range of steel bars the machine can handle, making it suitable for a wide variety of construction projects, from residential buildings to large infrastructure works.

These machines are integrated into cut and bend plants, where steel bars are processed efficiently from coil to finished stirrups, ready for concrete reinforcement.

Automatic Rebar bender Key Features and Specifications

Modern stirrup bending machines, such as itech 16 rebar bender equipment, incorporate advanced technology to optimize performance:

Wire Diameter Capacity: Handles single strand bars from 8mm up to 16mm, covering common rebar sizes.

Automatic Feeding and Straightening: Equipped with anti twist system straighteners and electronic settings to ensure smooth, twist-free wire feeding.

Dual Bending Heads: Machines like the itech 16 feature two bending units (upper and lower) for complex shapes and increased speed.

High-Speed Operation: Pulling speeds up to 100 m/min enable rapid production.

Cutting Mechanism: Adjustable wire guides with reversible blades ensure clean cuts without damaging the bar.

Servo Motor Drives: Electric servo motors provide precise control over bending angles and lengths with accuracy up to ±1° and ±1mm respectively.

Programmable Control Systems: CNC interfaces allow storage of multiple stirrup shapes and batch orders, facilitating flexible production.

Advantages of Using an Automatic Stirrups Bending Machine

Increased Productivity: Automated feeding, bending, and cutting enable continuous operation with minimal labor, significantly boosting output compared to manual methods.

Consistent Precision: Servo motors and CNC programming guarantee uniform shapes and angles, critical for structural integrity.

Versatility: Capable of processing various steel grades—cold-rolled, hot-rolled, ribbed, or smooth bars—across different diameters.

Space and Energy Efficient: Compact designs reduce workshop footprint, while low power consumption (around 5 kW/h) cuts operational costs.

User-Friendly Operation: Touchscreen controls and fault detection systems simplify use and maintenance.

Customization: Machines support custom shapes and dual-wire processing for complex stirrup designs.

Applications in Cut and Bend Plants

The 8-16mm automatic stirrup bending machine for coil is indispensable in cut and bend plants, where steel bars are processed for reinforced concrete structures. Typical applications include:

Residential and commercial building foundations

Bridge and tunnel reinforcements

Highway and railway infrastructure

Precast concrete manufacturing

By automating stirrup production, these machines reduce lead times and labor costs, ensuring projects stay on schedule and meet strict quality standards.

Maintenance Tips for Longevity

To maximize machine uptime and performance:

Regularly inspect and sharpen cutting blades.

Lubricate moving parts to prevent wear.

Keep electrical components and control panels clean and dry.

Check for air leaks in pneumatic systems.

Tighten bolts and fasteners periodically.

Following manufacturer guidelines ensures consistent operation and extends machine life.

Conclusion: Elevate Your Rebar Processing with Advanced Stirrup Benders

The 8-16mm automatic stirrup bending machine for coil in cut and bend plant is a vital investment for any modern construction or steel processing facility. Combining high-speed automation, precision control, and versatile programming, these machines streamline stirrup production, reduce labor costs, and improve structural quality.

Ready to upgrade your cut and bend plant? Explore leading models like itech or CNC stirrup benders from itech to find the perfect fit for your production needs.

Leave a Reply

Want to join the discussion?Feel free to contribute!