Maintaining and Troubleshooting Automatic Stirrup Bending Machines

Maintaining and Troubleshooting Automatic Stirrup Bending Machines: Cutting Servo Alarm with Dual Line Operations

Automatic stirrup bending machines are vital in the construction building materials industry, precast concrete,reinforcement steel prefabricate cut and bend factory. Rebar bending machine is for shaping steel bars into stirrups. However, like any sophisticated machinery, they require regular maintenance and troubleshooting to operate optimally. In this article, we delve into the maintenance practices and troubleshooting techniques for automatic stirrup bending machines, particularly focusing on addressing the cutting servo alarm when working with two lines.

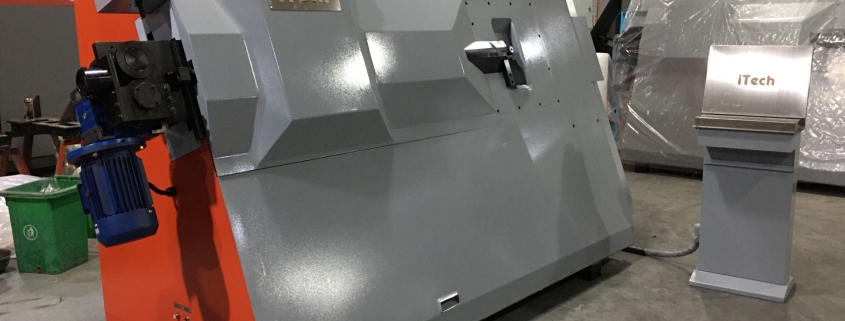

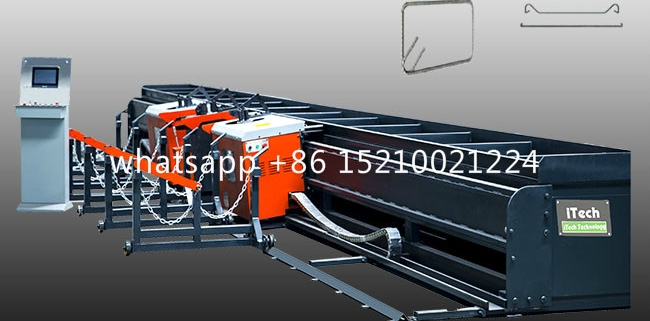

itech Best selling CNC high quality automatic stirrup bending machine / CNC stirrup bender machine widely use in reinforcement steel wire bar cut and bend factory. Itech as professional reinforcing steel machine supplier. Itech have a series of steel rebar bender machine,like CNC 16mm Stirrup Bending machine,CNC 20mm stirrup bar bending machine , 14mm stirrup wire bending machine and bar shape machine ,automatic rebar pile cage welding machine,cnc automatic pile cage making machine and many kinds of rebar machine. To solve the gap on the stirrups ,Itech stirrup bending machine adopt advanced anti twist feeding system to avoid twist of steel, make stirrup more quick and standard.Shape and bend stirrups effortlessly with our cutting-edge bending machine.

Understanding the Automatic Stirrup Bender Machine

Automatic stirrup bending machines are designed to transform long steel rods into various shapes, primarily used in reinforcing concrete structures. These machines are equipped with advanced features like cutting servos, which enhance their precision and speed. However, when operating with two lines, users may encounter a cutting servo alarm, indicating a malfunction that needs immediate attention.

Regular Maintenance Practices

To ensure the longevity and optimal performance of your automatic reinforcement steel wire stirrup bending machine, adhere to the following maintenance practices:

Routine Cleaning: After each use, clean the machine to remove debris, dust, and residue. This prevents buildup that could impair performance.

Lubrication: Regularly lubricate all moving parts as per the itech bending machine’s guidelines to reduce friction and wear.

Component Inspection: Frequently inspect the bending machine components, including wire bending machine tools, blades, and guides, for signs of wear and tear. Replace or repair damaged parts promptly.

Alignment Checks: Ensure the machine components are properly aligned to maintain bending accuracy. Misalignment can lead to faulty bends and compromise output quality.

Monitor Settings: Regularly monitor and adjust tension and pressure settings according to material and bending requirements. Incorrect settings can damage both the material and the machine.

Electrical Components: Ensure all electrical connections are secure and in good condition to avoid electrical issues.

Maintaining and Troubleshooting Automatic Stirrup Bending Machines: Cutting Servo Alarm with Dual Line Operations

When operating with two lines, encountering a cutting servo alarm can disrupt operations. Here are steps to troubleshoot and resolve this issue:

Check Servo Parameters: Ensure that the servo parameters are set correctly. Incorrect settings can cause communication errors and trigger alarms.

Inspect Communication Lines: Verify that the communication lines connecting the PLC to the servo are intact and functioning. Damaged or loose connections can lead to alarms.

Examine Terminal Resistors: If the last servo in the sequence has a terminal resistor, ensure it is correctly dialed. Incorrect resistor settings can cause malfunctions.

Review Axis Limits: Check if the axis limits are set appropriately. Exceeding these limits can trigger alarms. Adjust the limits or reset the reference points as needed.avoid the bender arm touch blade.adjust 0 position if happened this.

Emergency Stop Switch: Ensure that the emergency stop switch is released. A pressed switch can prevent the machine from operating correctly.

Inspect Feedback Signals: Check if there are feedback signals from the servo. Lack of feedback can indicate a wiring issue that needs addressing.

Check the cutting shaft and shaft cover, it should be connect well but no very tight,otherwise the cutting shaft will be block by the shaft cover. Especially when install cutting shaft and shaft cover, do not use hammer to hit directly. Hit to wood before shaft cover.

Conclusion

Maintaining and troubleshooting an automatic stirrup bending machine, especially when dealing with cutting servo alarms in dual line operations, requires meticulous attention to detail and adherence to best practices. By following regular maintenance routines and employing effective troubleshooting techniques, you can ensure your machine operates efficiently and reliably. For further assistance, consult the machine’s manual or reach out to professional technicians. Your proactive approach will not only extend the machine’s lifespan but also enhance productivity and safety in your operations.

For more insights and expert advice on maintaining bending machines, explore our resources or contact us for personalized support.

Itech is professional steel wire/bar processing machinery China supplier,stirrup bending machine price , steel rebar bending machine,foundation pile cage making machine,,steel wire straightener,wire straightening and cutting machine, wire mesh welding machine,rebar shear line,rebar sawing&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.

Maintaining and Troubleshooting Automatic Stirrup Bending Machines: Cutting Servo Alarm with Dual Line Operations

Automatic stirrup bending machines are vital in the construction building materials industry, precast concrete,reinforcement steel prefabricate cut and bend factory. Rebar bending machine is for shaping steel bars into stirrups. However, like any sophisticated machinery, they require regular maintenance and troubleshooting to operate optimally. In this article, we delve into the maintenance practices and troubleshooting techniques for automatic stirrup bending machines, particularly focusing on addressing the cutting servo alarm when working with two lines.

itech Best selling CNC high quality automatic stirrup bending machine / CNC stirrup bender machine widely use in reinforcement steel wire bar cut and bend factory. Itech as professional reinforcing steel machine supplier. Itech have a series of steel rebar bender machine,like CNC 16mm Stirrup Bending machine,CNC 20mm stirrup bar bending machine , 14mm stirrup wire bending machine and bar shape machine ,automatic rebar pile cage welding machine,cnc automatic pile cage making machine and many kinds of rebar machine. To solve the gap on the stirrups ,Itech stirrup bending machine adopt advanced anti twist feeding system to avoid twist of steel, make stirrup more quick and standard.Shape and bend stirrups effortlessly with our cutting-edge bending machine.

www.itechbendingmachine.com

whatsapp+8615210021224

Automatic Rebar Stirrup Bender CNC Steel Bar Stirrup Bending Machine Automatic Steel Bending Hoop Machine آلة ثني الفولاذ التلقائية Automatische buigmachine voor stalen staven Mesin ring bending baja otomatis 自動スチールベンディングフープマシン 자동 스틸 바 벤딩 머신 Автомат ган гулзайлтын машин Автоматическая машина для гибки стальных пялец Dobladora automática de aro de acero Máy uốn thép tự động #construction #Machinetools #engineering #technology #constructionmachinery #Heavymachinery #rebarbender #stirrupbender #stirrupbendingmachine #cncrebarstirrupbener #steelbarbender #steelbarstirrpbender #hoopbender #hoopbendingmachine #rebarmachine #rebarbending #rebarhoopbender #steelbarhoopbendingmachine

#stirrupbender,#stirrupbendingmachine,#rebarbender,#rebarcutter,#barbendingmachine,#ironformingmachine,

#pilecagemachine,#wiremeshweldingmachine,#meshmachine,#doublebender,#rebarshearline,

#straighteningmachine,#straighteningandcuttingmachine,

#wirestraigtener,#rebarthreading #rebar #steel #staal #telaviv #moscow #texas #constructionlife #iron #mills #stirrups #best #buildings #industrialdesign #wire nb #machinery #steelwire #dubai #israel #bendingmachine #spain #germany #france #Netherlands #holland #belgium #ireland #england #unitedkingdom

Itech is professional steel wire/bar processing machinery China supplier,stirrup bending machine price , steel rebar bending machine,foundation pile cage making machine,,steel wire straightener,wire straightening and cutting machine, wire mesh welding machine,rebar shear line,rebar sawing&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.

rebar bender

rebar bender

wire straightening and cutting machine

wire straightening and cutting machine rebar double bender

rebar double bender

steel reinforcement stirrup bending machine

steel reinforcement stirrup bending machine rebar bender

rebar bender  stirrups bender

stirrups bender

wire mesh

wire mesh

pile cage machine

pile cage machine