Reinforcement Rebar pile cage welding machine Cut&bend Equipment

Reinforcement Rebar pile cage welding machine Cut&bend Equipment

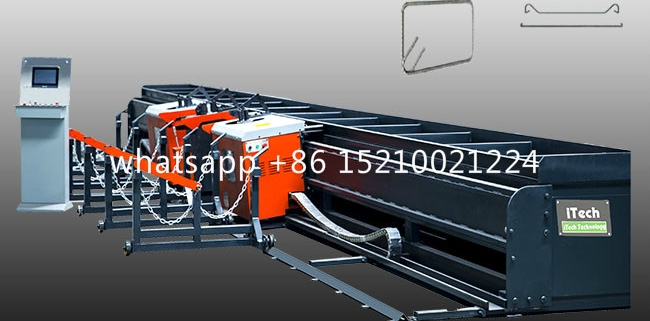

Reinforcement Rebar pile cage welding machine Cut&bend Equipment is an essential tool.It is wildly use for bridge,construction,foundation or reinforcement steel wire bar fabrication industry.A pile cage machine is an advanced welding system designed to automate the production of rebar cages used in construction, particularly for bored piles, diaphragm walls, and foundation reinforcement. This innovative equipment enhances efficiency, precision, and safety in manufacturing reinforcement cages, making it indispensable for modern construction projects.

Itech Best selling CNC high quality automatic stirrup bending machine / CNC stirrup bender machine widely use in reinforcement steel wire bar cut and bend factory. Itech as professional reinforcing steel machine supplier. Itech have a series of steel rebar bender machine,like CNC 16mm Stirrup Bending machine,CNC 20mm stirrup bar bending machine , 14mm stirrup wire bending machine and bar shape machine ,automatic rebar pile cage welding machine,cnc automatic pile cage making machine and many kinds of rebar machine. To solve the gap on the stirrups ,Itech stirrup bending machine adopt advanced anti twist feeding system to avoid twist of steel, make stirrup more quick and standard.Shape and bend stirrups effortlessly with our cutting-edge bending machine.

Key Features of a Pile Cage Machine

Automated Welding: Reduces labor costs and increases production speed.

Precision Engineering: Ensures accurate spacing and alignment of rebars.

Adjustable Diameter & Length: Can produce cages of various sizes for different project requirements.

High-Speed Production: Capable of fabricating long rebar cages in minutes.

Durability & Reliability: Built with robust materials for long-term performance.

Applications of Rebar Cage Machines

Pile cage welding machines are widely used in:

Bored Pile Construction – For foundation reinforcement in bridges, high-rise buildings, and infrastructure projects.

Tunnel & Underground Works – Reinforcing diaphragm walls and secant piles.

Marine & Offshore Structures – Providing strong reinforcement for deep foundations.

Wind Turbine Foundations – Ensuring stability for large-scale renewable energy projects.

Advantages of Using a Cage Welding Machine

Increased Productivity: Automates the welding process, reducing production time by up to 80%.

Cost-Effective: Minimizes labor costs and material waste.

Superior Weld Quality: Ensures consistent, high-strength welds for durable reinforcement.

Enhanced Safety: Reduces manual handling of heavy rebars, lowering workplace injuries.

Customization Designs: Adaptable to different rebar sizes and cage configurations.

Choosing the Best Pile Cage Machine for Your Project

When selecting a rebar cage machine, consider:

Welding Speed & Capacity – How many cages can it produce per hour?

Diameter & Length Range – Does it meet your project specifications?

Automation Level – Fully automatic vs. semi-automatic models.

Brand Reputation & After-Sales Support – Reliable manufacturers ensure long-term service

Conclusion

Investing in a high-quality pile cage machine (or cage welding machine) is a smart decision for construction companies looking to improve efficiency, reduce costs, and enhance structural reliability. Whether for bored piles, tunnels, or wind turbine foundations, an automated rebar cage machine delivers unmatched performance and precision.

Itech is professional steel wire/bar processing machinery China supplier,stirrup bending machine price , steel rebar bending machine,foundation pile cage making machine,,steel wire straightener,wire straightening and cutting machine, wire mesh welding machine,rebar shear line,rebar sawing&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.

For top-tier pile cage welding solutions, explore leading manufacturers and find China itech best pile cage machine to meet your construction needs today!

cage welding machine

cage welding machine

concrete show south america

concrete show south america rebar double bender

rebar double bender