Happy New Year from iTech: Rebar Cutting Machine and Rebar Bending Machine Supplier Greetings

Happy New Year from iTech: Rebar Cutting Machine and Rebar Bending Machine Supplier Greetings

As we step into a brand new year, iTech , as your trusted supplier of rebar cutting machines and rebar bending machines, extends warm and heartfelt Happy New Year greetings to all our valued customers, partners, and industry friends. This year marks another exciting chapter in our commitment to providing high-quality steel wire bar processing machinery that powers construction projects worldwide. Join us as we celebrate innovation, quality, and partnership in the reinforcement steel rebar machinery industry.

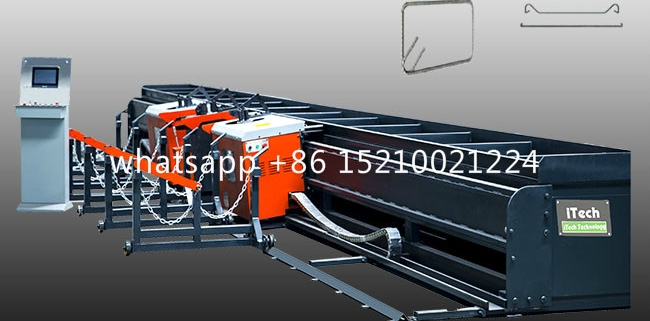

itech Best selling CNC high quality automatic stirrup bending machine / CNC stirrup bender machine widely use in reinforcement steel wire bar cut and bend factory. Itech as professional reinforcing steel machine supplier. Itech have a series of steel rebar bender machine,like CNC 16mm Stirrup Bending machine,CNC 20mm stirrup bar bending machine , 14mm stirrup wire bending machine and bar shape machine ,automatic rebar pile cage welding machine,cnc automatic pile cage making machine , automatic truss lattice girder welding machine and many kinds of rebar machine. To solve the gap on the stirrups ,Itech stirrup bending machine adopt advanced anti twist feeding system to avoid twist of steel, make stirrup more quick and standard.Shape and bend stirrups effortlessly with our cutting-edge bending machine.

Welcome the New Year with iTech’s Premium Rebar Machines

At iTech, we understand that the backbone of any construction project lies in the strength and precision of its reinforcement steel bars. As a professional supplier specializing in rebar bending machines, rebar cutting machines, and related equipment such as stirrup benders and wire mesh welding machines, we are proud to support your construction needs with advanced technology and reliable service.

Our comprehensive product lineup includes:

Automatic Rebar Bending Machines: Featuring precise CNC controls and durable components like servo systems and encoders, our bending machines offer accurate angles and high efficiency for various bar diameters.

Rebar Cutting Machines: Hydraulic and electric models designed for clean, fast cuts on round, deformed, square, or flat bars, ensuring exact lengths for construction specifications.

Automatic Stirrup Benders and Double rebar Benders: Specialized equipment for creating stirrups, hoops, and complex shapes with ease and consistency.

Wire Mesh Welding and Cage Making Machines: For producing reinforced steel cages and wire mesh used in slabs, walls, and infrastructure projects.

Why Choose iTech for Your Rebar Processing Needs?

As we greet the new year, it’s important to reflect on why iTech remains a top choice for rebar machinery worldwide. Here’s what sets us apart:

High-Quality Components and Durability,We integrate premium parts such as high quality servo systems and best quality encoder systems to ensure long-lasting performance and precision.

Experienced Engineering Team;Our engineers bring over five years of expertise, offering tailored solutions and 24/7 support to guarantee your machinery runs smoothly.

Comprehensive After-Sales Service, From pre-sales consultation to post-delivery maintenance, our dedicated team is available around the clock to assist you.

Fast Delivery and Quality Assurance,We commit to on-time delivery with 100% inspection during production and before shipment, ensuring your machines meet the highest standards.

Global Customer Satisfaction,Trusted by clients worldwide, iTech machines are used in residential, commercial, and infrastructure projects, enhancing construction efficiency and safety.

Innovations to Look Forward to in 2026

The new year brings exciting advancements in rebar processing technology. iTech continues to innovate with:

Automated CNC Stirrup Bending Machines for faster, more precise bending with programmable multi-angle functions.

High-Speed Rebar Cutting and Shearing Lines that increase productivity on-site.

Energy-Efficient Electric Rebar Benders designed for portability and ease of use on smaller projects.

These innovations not only improve construction workflows but also reduce labor costs and enhance structural integrity.

Tips for Maintaining Your Rebar Machines in the New Year

To maximize the lifespan and efficiency of your rebar cutting and bending machines, consider these maintenance best practices:

Clean machine surfaces regularly with soft cloths and neutral detergents.

Lubricate moving parts such as bearings and chains to prevent wear.

Inspect electrical systems and hydraulic components to avoid malfunctions.

Replace worn blades, belts, and other parts promptly.

Maintain proper cooling by checking fans and radiators.

Routine maintenance ensures consistent performance and reduces downtime, helping you meet project deadlines.

Celebrate the New Year with iTech

As we celebrate the arrival of 2026, iTech wishes all our clients and partners a prosperous and successful year ahead. Whether you are upgrading your equipment or starting new construction ventures, our rebar bending machine and rebar cutting machine are designed to meet your highest expectations.

Contact us today to learn more about our products and services, and let’s build a stronger future together.

stirrup bender

stirrup bender  stirrup bending machine

stirrup bending machine rebar double bender

rebar double bender

rebar bender

rebar bender

spiral making machine

spiral making machine

steel reinforcement stirrup bending machine

steel reinforcement stirrup bending machine

stirrups bender

stirrups bender  cut and bend machine

cut and bend machine

rebar stirrup bender

rebar stirrup bender