Rebar Double Bender Boosting Efficiency and Accuracy

Rebar Double Bender Boosting Efficiency and Accuracy

in the construction industry and cut bend factory, reinforcing steel bars, commonly known as rebar, play a vital role in providing strength and stability to concrete structures. To meet the growing demand for rebar processing, itech rebar machine have developed innovative machinery, such as rebar double benders, which revolutionize the bending and shaping process. This article will explore the features, benefits, and applications of rebar double benders.

We have a series of steel rebar bender machine,like CNC 16mm Stirrup Bending machine,CNC stirrup bar bending machine,stirrup wire bending machine and bar shape machine.advanced anti twist feeding system to avoid twist of steel, make stirrup more quick and standard. Rebar cutting system is used multi-faceted with a knife design. With international servo drive, high speed to feeding,big production capacity was highly improved.

Features of Rebar Double Bender:

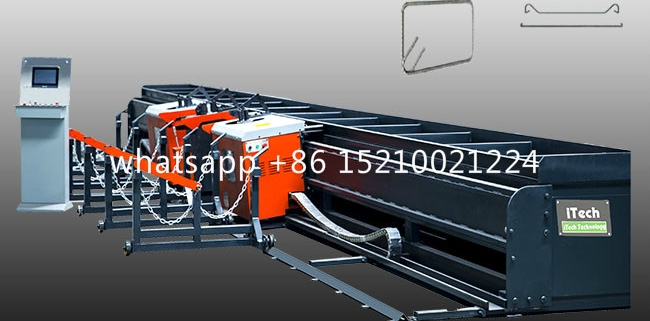

Stirrup Rebar double bending machine are sophisticated machines that are specifically designed to automate the bending reinforcement bars. These machines typically feature two bending heads, which simultaneously bend iron rebar to create shapes required for various construction applications. Some notable features include:

- Dual Bending Heads: The presence of two bending heads enables simultaneous bending, which significantly reduces processing time compared to single-head machines.

- Programmable Control System: Rebar stirrup double bending lineare equipped with advanced control systems that enable precise and accurate positioning of bending heads. Operators can input specific bending angles and lengths, ensuring consistent and uniform bends throughout the production process.

- High Bending Capacity: Rebar double stirrup bender are capable of bending different rebar sizes and grades, catering to various construction requirements. They can handle rebar diameters ranging from a few millimeters to several centimeters, providing flexibility and versatility in production.

Benefits of Rebar Double stirrup Bending machine:

The utilization of rebar double benders in cut bend factory and manufacturing processes offers several advantages, including:

- Enhanced Efficiency: With their dual bending heads, rebar double benders enable fast and simultaneous bending, improving overall production speed. This increased efficiency allows construction projects to meet strict deadlines and reduces labor costs.

- Improved Accuracy: steel Rebar double benders feature precise control systems that ensure consistent bending angles and lengths. This accuracy promotes structural integrity, reduces material waste, and eliminates rework, resulting in cost savings.

- Increased Worker Safety: By automating the bending process, rebar double benders minimize the risk of repetitive strain injuries and accidents associated with manual labor. Operators are no longer required to physically manipulate heavy rebar, reducing the physical strain on workers.

Applications of Rebar Double Benders:

Rebar double benders find applications in a wide range of construction projects, such as:

- High-Rise Buildings: Rebar double benders are ideal for high-rise structures that require a significant amount of reinforcement. They efficiently bend and shape rebar to create the intricate designs needed for columns, beams, and slabs.

- Bridge Construction: Bridges often involve complex rebar configurations. Double benders enable the bending of large quantities of rebar with precision, ensuring structural integrity and durability.

- Infrastructure Projects: Rebar double benders are widely used in infrastructure projects, including tunnels, dams, and highways. These machines can handle the high volume of rebar required for such large-scale projects, providing consistent quality and reducing construction timelines.

Conclusion:

Reinforcement steel Rebar double bending line have become indispensable tools in the construction industry, offering unparalleled efficiency, accuracy, and safety. Their ability to process rebar quickly and uniformly has revolutionized the reinforcement bending process, enhancing structural strength and quality. As technology continues to advance, rebar horizontal double benders will play an increasingly essential role in delivering successful and sustainable construction projects.

Itech is good steel wire/bar processing machinery China supplier,stirrup bending machine, rebar bending machine,cage making machine,,steel wire straightener, wire mesh welding machine,rebar shear line,sawing&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.https://itechbendingmachine.com/

rebar double bender

rebar double bender

rebar bender

rebar bender  cage welding machine

cage welding machine

Leave a Reply

Want to join the discussion?Feel free to contribute!