rebar double bending machine instructions( bar shaping machine use )

This is the CNC automatic rebar double bending machine / automatic bar shaping machine instructions .High-efficiency products CNC automatic rebar double bending machine / automatic bar shaping machine is specially designed for steel wire / bar processing factory,cut and bend factory, concrete plant, construction company, high-rise buildings, highways, high-speed railways, large bridge engineering from iTech,CNC automatic rebar double bending machine / automatic bar shaping machine can process deformed rebar diameter up to φ32mm. CNC automatic rebar double bending machine / automatic bar shaping machine have one pneumatic clamp device and two bending head can move and bending freely on a specific track, the most importance of CNC automatic rebar double bending machine / automatic bar shaping machine is that two bending head can bending rebar at same time.We strive to pursue humanity in research and development to meet the needs of people at all levels. At the same time, high processing accuracy and efficiency , which can meet the requirements of the project schedule. Compared with ordinary manual bending machine , each shift can replace the processing capacity of 10 manual operators. Bring tangible benefits.

CNC automatic rebar double bending machine / automatic bar shaping machine instructions mainly including the bending head device, frame and main machine body, automatic sizing device and service part.check video from itech youtube channel https://www.youtube.com/watch?v=8TuRb_nAk0o

1.The bending head device of CNC automatic rebar double bending machine / automatic bar shaping machine

The bending head has a compact structure, a wide range of processing steel bars, and has independent and intelligent design. The movement of the bending head is driven by servo motor, and the bending length of the steel bar is digitally controlled. The head movement response is fast and the positioning accuracy is high. The bending motor adopts frequency conversion technology, the steel bar is processed accurately and energy saving. Multiple bars can be bent to improve production at the same time.

2.The frame and main body of CNC automatic rebar double bending machine / automatic bar shaping machine

Automatic transport system can transport rebar directly,no need people to take one by one ,The curved platform rail adopts high-strength movable rail, which is sturdy and durable and not easily deformed. High-strength automatic storage rack can realize continuous production.

3.The sizing device of CNC automatic rebar double bending machine / automatic bar shaping machine

The automatic sizing device is used to determine the position of the end of the steel bar. It is controlled by servo motor and automatically positioned, without manual measurement and fixing, with high positioning accuracy and high reliability. It has an automatic locking mechanism to ensure the positioning accuracy of the steel end. The swing baffle of the equipment will automatically avoid the steel bars to ensure the bending accuracy of the steel bars.

The advantage of CNC automatic rebar double bending machine / automatic bar shaping machine

- The equipment has two independent bending centers, which can simultaneously or independently bend various shapes of stirrups, greatly improving efficiency and working speed, and reducing labor and cost.

- The bending host adopts Japanese original technology and mechanical principles, with reasonable structure design, large bending force, and convenient and accurate angle adjustment.

- The automatic motion system adopts servo motor drive, rack and pinion drive, with small error and fast response speed.

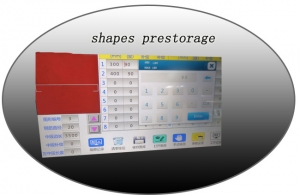

- The electronic control system adopts CNC automaticcontrol, which can realize the functions of automatic fault identification, graphic editing, and process.

- It is a necessary tool for the standardization of steel bar processing plantsand cut and bend factory.

- Rolling feeding platform, equipped with feeding motor. Can carry a large amount of raw materials, convenient and labor-saving for loading and unloading;

- After the screen graphics are edited and downloaded, the blanking length of the raw materials is automatically displayed, which is convenient for the operator to operate;

CNC automatic rebar double bending machine / automatic bar shaping machine instructions service part

Perfect management system and system:

- Pre-sale service. Set up a special sales service organization, the company will arrange relevant professionals to be responsible for training and installation.

- In-sale service. In order to prevent users from improper use and cause unnecessary losses, the company will send relevant technical personnel to the construction site to provide technical guidance to users during the use of the equipment. Ensure that the equipment is used correctly, so that users can use it with peace of mind.

- After-sales service. Our company responds to maintenance services and arrives at the site for maintenance , in order to better perform equipment after-sales service work, and timely solvedcustomer feedback problems.

For more information,please check our website page www.itechbendingmachine.com/

stirrup bending machine itech

stirrup bending machine itech