Rebar bending machine for sale

Rebar bending machine is one of important rebar processing equipment, it is wildly use in construction site, precast company, concrete company and cut&bend factory.

Actually, many construction site use small straightening&cutting machine, small manual rebar bender,small manual rebar cutter, manual threading machine. One reason is that the space is not big enough, another is the automatic machine production capacity is higher than requirement, need space to storage. Cut and bend factory use more rebar machine. Rebar bending machine is must. But do you know the different between line type rebar bending machine and S type rebar bending machine?

https://www.facebook.com/rebarmachine

As well known, rebar bending machine use rollers to make wire straight, bend different shapes, and cut finally. If you use stirrup bender before, it will have two wire twist when machine work with line type stirrup bender. Otherwise you will s type ,there is no twist. Why? It is because the s type stirrup bender have anti-twist function. Let we see what’s difference between line type steel wire stirrup bender and s type stirrup bender?

Line type stirrup bender

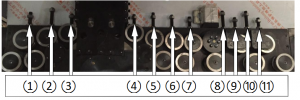

8, 9, 10, 11, 12, 13, 14-fixed straightening wheel 1, 2, 3, 4, 5-movable straightening wheel, 6, 7-direction control wheel

The straightening of the automatic stirrup bending machine is carried out by two sets of multi-wheel straightening and straightening systems with mobile memory testing in the position, dismantling and replacing building steel bars with different diameters, and the straightening wheels will automatically adjust downwards or upwards to carry out building reinforcement Straighten quickly, reduce construction steel

The whole process of bar straightening time is fully automatic. The multi-wheel group pulls the building steel bar synchronously. The working pressure of the wheel and the building steel bar is reduced, and the driving force is small, thereby reducing energy consumption and building steel loss. However, the disadvantage is that the contact point of the steel bar is small, the steel bar is damaged when pressed too tightly, the wheel is slipped and cannot be processed when the press is too light, and the problem of torsion of the steel bar cannot be avoided.

1, 2, 3, 4, 5,6,7 fixed straightening wheel-movable straightening wheel, 8, 9,10,11-direction control wheel

There is 12cm length between 3-4 wheel, so the steel is press by the big wheel, big weave,the steel attach the big roller, no any twist. So the straightening better and also the finial stirrups all more standard.It is the most advantage of S type rebar bending machine than line type rebar bending machine.

Itech as one professional steel wire/bar processing machinery China supplier,stirrup bending machine, rebar bending machine,cage making machine,wire mesh welding machine,rebar shear line,saw&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.

https://itechbendingmachine.com/products/wire-bending-machine/

itech qatar

itech qatar cage making machine itech

cage making machine itech