Itech reinforcement steel wire stirrup bender rebar double bender rebar processing machine: Thanks to Our Customers who serve as our teachers

Itech reinforcement steel wire stirrup bender rebar double bender rebar processing machine: Thanks to Our Customers who serve as our teachers

In the dynamic world of construction and infrastructure, the demand for innovative reinforcing steel wire rebar processing machines is ever-growing. Itech, a leading supplier of steel wire and bar processing machinery, has consistently been at the forefront of providing high-quality solutions to meet the industry’s evolving needs. This article delves into the significance of the Itech rebar machine, acknowledging our customers who have been instrumental as our teachers in shaping our products and services.

The Role of Itech Rebar Machines in Modern Construction

Itech rebar machines are essential tools in reinforcing steel cut and bend factories, playing a crucial role in the construction industry. These machines are designed to enhance efficiency and precision in the bending and cutting of steel bars, ensuring structural integrity and safety in construction projects. Our range includes the fastest high-speed straightening and cutting machines, stirrup benders, and cage making machines, all engineered to meet diverse project requirements.It is widely used rebar machines in rebar cut and bend plant, concrete precast factory,infrastructure construction company, pile drilling company, building materials factory or store.

itech Best selling CNC high quality automatic stirrup bending machine / CNC stirrup bender machine widely use in reinforcement steel wire bar cut and bend factory. Itech as professional reinforcing steel machine supplier. Itech have a series of steel rebar bender machine,like CNC 16mm Stirrup Bending machine,CNC 20mm stirrup bar bending machine , 14mm stirrup wire bending machine and bar shape machine ,automatic rebar pile cage welding machine,cnc automatic pile cage making machine and many kinds of rebar machine. To solve the gap on the stirrups ,Itech stirrup bending machine adopt advanced anti twist feeding system to avoid twist of steel, make stirrup more quick and standard.Shape and bend stirrups effortlessly with our cutting-edge bending machine.

Key Features of Itech Rebar Stirrup Bending Machines

High-Speed Operation: Our machines boast high-speed straightening and cutting capabilities, significantly reducing processing time.

Precision and Accuracy: Equipped with advanced servo motor control systems, Itech machines ensure minimal tolerance and high precision in bending and cutting operations.

Versatility: Capable of handling various sizes and diameters of steel bars, our machines are adaptable to different construction needs.

Safety Mechanisms: With integrated safety features, our machines minimize workplace accidents and ensure safe operations.

Learning from Our Customers: A Journey of Continuous Improvement

At Itech, we believe that our customers are our greatest teachers. Their feedback and insights have been invaluable in refining our products and services. By actively listening to their needs and challenges, we have been able to innovate and enhance our rebar machines to better serve the industry.

Customer-Driven Innovations

Advanced Anti-Twist System Stirrup bender: To address the issue of twisted stirrups, we developed an advanced anti-twist feeding system, ensuring quick and standard stirrup production.

Enhanced Automation: Our customers’ demand for increased efficiency led to the integration of cutting-edge automation features, boosting factory throughput and product quality.

Customization Options: Understanding the diverse requirements of different projects, we offer customization options for our machines, providing flexibility and adaptability to meet specific customer needs.

Itech reinforcement steel wire stirrup bender rebar double bender rebar processing machine: Thanks to Our Customers who serve as our teachers

As we continue to innovate and improve our rebar machines, we extend our heartfelt gratitude to our customers who have been pivotal in guiding our journey. Their role as our teachers has been instrumental in shaping our products and services, ensuring we deliver the best solutions to meet the industry’s needs. We invite you to explore our range of rebar machines at itechbendingmachine.com and experience the impact of customer-driven innovation firsthand. Join us in building a future of excellence in construction and infrastructure.

Itech is professional steel wire/bar processing machinery China supplier,stirrup bending machine price , steel rebar bending machine,foundation pile cage making machine,,steel wire straightener,wire straightening and cutting machine, wire mesh welding machine,rebar shear line,rebar sawing&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.

High Speed Automatic Stirrup Bender in reinforcement steel rebar cut and bend factory

High Speed Automatic Stirrup Bender in reinforcement steel rebar cut and bend factory

High Speed Automatic Stirrup Bender in reinforcement steel rebar cut and bend factory. It make wire straightening,bending and cutting all in one. It is designed to process wire, bending shapes with accurate length and angle size. It is widely used rebar machines in rebar cut and bend plant, concrete precast factory,infrastructure construction company, pile drilling company, building materials factory or store.

itech Best selling CNC high quality automatic stirrup bending machine / CNC stirrup bender machine widely use in reinforcement steel wire bar cut and bend factory. Itech as professional reinforcing steel machine supplier. Itech have a series of steel rebar bender machine,like CNC 16mm Stirrup Bending machine,CNC 20mm stirrup bar bending machine , 14mm stirrup wire bending machine and bar shape machine ,automatic rebar pile cage welding machine,cnc automatic pile cage making machine and many kinds of rebar machine. To solve the gap on the stirrups ,Itech stirrup bending machine adopt advanced anti twist feeding system to avoid twist of steel, make stirrup more quick and standard.Shape and bend stirrups effortlessly with our cutting-edge bending machine.

Key Features of itech High Speed Automatic Stirrup Bending machine

- Advanced CNC touch screen PLC Control Systems

High-speed automatic electrical servo stirrup benders are equipped with sophisticated CNC (Computer Numerical Control) systems. These systems ensure high precision and minimal error, allowing for complex bending tasks to be performed with ease. The CNC control system provides bi-directional bending capabilities, enabling the creation of various shaped pieces.

- fast speed rebar machine High Production Capacity

These machines boast impressive production capabilities. For instance, itech models 6-12mm automatic stirrup bending machine can process up to 900-1000 pieces per hour with single wire and 1800-2000 pieces with double wire. This high throughput is ideal for large-scale projects requiring a constant supply of bent steel bars.

- Durability and Reliabilityanti twist stirrup bender

Constructed with high-quality materials, including alloy mold steels and wear-resistant components, these machines are built to last. The use of advanced heat-treatment processes ensures the longevity of cutting tools, reducing maintenance costs and downtime.

- Precision and Accuracy rebar machines

Precision is a hallmark of high-speed automatic stirrup benders. With a length accuracy of ±1 mm and angle accuracy of ±1°, these machines deliver consistent and reliable results. This precision is crucial for maintaining structural integrity in construction projects.

Benefits of Using High-Speed Automatic Stirrup Benders

- Enhanced Efficiency

The automation of the bending process significantly reduces manual labor, allowing workers to focus on other critical tasks. This efficiency translates into cost savings and faster project completion times.

- Improved Safety

Manual bending of steel bars can be hazardous. Automatic stirrup benders minimize the risk of workplace injuries by reducing the need for manual handling of heavy materials.

- Cost-Effectiveness

While the initial investment in a high-speed automatic stirrup bender may be significant, the long-term savings on labor costs and increased productivity make it a worthwhile investment for construction companies.

- Versatility

These machines are versatile, handling various steel bar sizes and shapes. This adaptability makes them suitable for a wide range of construction applications, from residential buildings to large infrastructure projects.

Itech is professional steel wire/bar processing machinery China supplier,stirrup bending machine price , steel rebar bending machine,foundation pile cage making machine,,steel wire straightener,wire straightening and cutting machine, wire mesh welding machine,rebar shear line,rebar sawing&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.

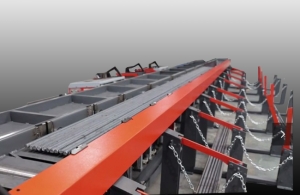

12m Automatic Rebar Double Bender Maximize Efficiency with the reinforcement bar double head bending machine line

12m Automatic Rebar Double Bender Maximize Efficiency with the reinforcement bar double head bending machine line

In the construction industry and rebar cut and bend factory, rebar bending line is wildly use. The 12m automatic rebar double bender stands out as automatic rebar processing machine tool, improve rebar bending process for steel bars and fast enhancing production capacity. Whether you’re involved in high-speed rail projects, bridge construction, precast factory or residential developments, rebar machine is designed to meet diverse needs with unparalleled accuracy.

itech Best selling CNC high quality automatic stirrup bending machine / CNC stirrup bender machine widely use in reinforcement steel wire bar cut and bend factory. Itech as professional reinforcing steel machine supplier. Itech have a series of steel rebar bender machine,like CNC 16mm Stirrup Bending machine,CNC 20mm stirrup bar bending machine , 14mm stirrup wire bending machine and bar shape machine ,automatic rebar pile cage welding machine,cnc automatic pile cage making machine and many kinds of rebar machine. To solve the gap on the stirrups ,Itech stirrup bending machine adopt advanced anti twist feeding system to avoid twist of steel, make stirrup more quick and standard.Shape and bend stirrups effortlessly with our cutting-edge bending machine.

Understanding the 12m Automatic Rebar Double Bender

The 12m automatic rebar double bender is an advanced piece of rebar machinery that automates the bending of steel bars, accommodating various shapes and angles. Usually it can bender diameter up to 40mm or 50mm, which makes it suitable for a wide array of construction applications. With features like automatic feeding and discharging systems, pneumatic ejection, and digital electric servo motors, this machine ensures smooth operations and high precision.

Key Features and Benefits

- Automatic Operations reinforcing steel cut and bend machine

Efficiency: The machine operates automatically, minimizing manual intervention and reducing labor costs.

Precision: Servo motors provide accurate bending angles, ensuring consistency across all projects.

- Versatile Bending Capabilities double head rebar machine

Complex Shapes: It can bend positive and negative shapes, including intricate designs like horseshoe tendons.

Adjustable Speeds: steel bar bending line machine offers adjustable bending speeds, allowing customization based on project requirements.

Industry Applications : 12m Automatic Rebar Double Bender Maximize Efficiency with the reinforcement bar double head bending machine line

itech 12m automatic rebar double bender is ideal for various construction projects, including:

High-speed Railways: Its precision and speed make it perfect for large-scale infrastructure projects.

Bridge Construction: The machine’s ability to handle complex shapes ensures structural integrity.

Residential Buildings: Streamlined operations reduce project timelines and improve cost efficiency.

Choosing the Right Machine

When selecting a 12m automatic rebar double bender, consider the following factors:

Tonnage: Determines the bending force and impacts the machine’s ability to handle different materials.

quality: itech double bender is high quality and durable machine.

Size: Ensure the machine fits within your workspace without requiring extensive rearrangements.

Leading Suppliers and Models

Several notable suppliers offer high-quality 12m automatic rebar double benders. For instance,itech provide machines ensure reliability and performance. The itech model T50, for example, boasts a wide range of features, including CNC control and a maximum bending angle of 180°, making it a top choice for precise operations.

Conclusion

The 12m automatic rebar double bender is an indispensable tool for modern construction projects, offering efficiency, precision, and versatility. By investing in this advanced machinery, construction firms can significantly improve their productivity and reduce labor costs. Explore options from itech reputable suppliers and choose a model that aligns with your specific project needs.

For more information on purchasing a 12m automatic rebar double head bender, visit trusted platforms like itech or contact suppliers directly to discuss your requirements. Embrace the future of construction with this innovative technology and elevate your projects to new heights.

Itech rebar processing machine at the 2025 China Wire and Tube Show: A Premier Event for Industry Professionals

Itech rebar processing machine at the 2025 China Wire and Tube Show: A Premier Event for Industry Professionals

The 2025 China Wire and Tube Show is set to be a landmark event in the global wire and cable industry. Scheduled to take place from August 27 to August 29, 2025, at the Shanghai New International Expo Center in Pudong New Area, Shanghai, this exhibition promises to be a hub of innovation, networking, and business opportunities. As one of the most significant events in Asia, the WireShow 2025 play a crucial role in shaping the future of the wire and cable sector.

itech Best selling CNC high quality automatic stirrup bending machine / CNC stirrup bender machine widely use in reinforcement steel wire bar cut and bend factory. Itech as professional reinforcing steel machine supplier. Itech have a series of steel rebar bender machine,like CNC 16mm Stirrup Bending machine,CNC 20mm stirrup bar bending machine , 14mm stirrup wire bending machine and bar shape machine ,automatic rebar pile cage welding machine,cnc automatic pile cage making machine and many kinds of rebar machine. To solve the gap on the stirrups ,Itech stirrup bending machine adopt advanced anti twist feeding system to avoid twist of steel, make stirrup more quick and standard.Shape and bend stirrups effortlessly with our cutting-edge bending machine.

Why Attend the 2025 China Wire and Tube Show?

The Wire Show 2025 is not just another trade fair; it is a comprehensive platform that covers the entire industry chain of the wire and cable sector. Over 700 exhibitors will showcase their latest products and technologies across 57,500 square meters of exhibition space. This event is an excellent opportunity for industry professionals to gain insights into the latest trends, discover market opportunities, and explore development paths.

Key Highlights of the Event

Exhibitor Showcase: The exhibition will feature an extensive range of products, including wire processing machinery, cable manufacturing equipment, raw and auxiliary materials, specialty cables, and testing systems. This diverse showcase will provide attendees with a comprehensive view of the industry’s innovations and advancements.

Technical Forums: More than 30 technical forums will be held concurrently, offering in-depth discussions on advancements and solutions across the sector. These forums are designed to enhance international exchange and present innovative products and technologies.

Networking Opportunities: The Wire Show 2025 will serve as a powerful bridge for cable companies to explore the market. Attendees will have the chance to network with industry colleagues, suppliers, and potential clients, fostering valuable business relationships.

Itech rebar processing machine at the 2025 China Wire and Tube Show: A Premier Event for Industry Professionals

The 2025 China Wire and Tube Show is an unmissable event for anyone involved in the wire and cable industry. With its comprehensive showcase of products, cutting-edge technologies, and insightful forums, the Wire Show 2025 promises to be a pivotal event for industry professionals looking to stay ahead of the curve. Don’t miss the opportunity to be part of this dynamic event—mark your calendars for August 27-29, 2025, and join us in Shanghai for an unforgettable experience.

Itech is professional steel wire/bar processing machinery China supplier,stirrup bending machine price , steel rebar bending machine,foundation pile cage making machine,,steel wire straightener,wire straightening and cutting machine, wire mesh welding machine,rebar shear line,rebar sawing&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.

Discover the Concrete Show São Paulo 2025: A Premier Event for rebar processing machine Construction Industry Professionals

Discover the Concrete Show São Paulo 2025: A Premier Event for rebar processing machine Construction Industry Professionals

The Concrete Show São Paulo 2025 fair is set to be an unmissable event for those in the construction industry, bringing together the latest innovations, technologies, and trends in concrete technology. As the 16th edition of this renowned event, it promises to offer an unparalleled platform for networking, business development, and professional growth. Held at the São Paulo Expo Exhibition & Convention Center from August 19 to 21, 2025, this international fair is dedicated exclusively to construction industry professionals. Rebar processing machine as important tools for concrete precast factory, cut and bend plant, construction company, foundation drill company. Itech as rebar machine leading supplier, aslo can provide complete solution for all the Concrete Show São Paulo 2025 vistors.

itech Best selling CNC high quality automatic stirrup bending machine / CNC stirrup bender machine widely use in reinforcement steel wire bar cut and bend factory. Itech as professional reinforcing steel machine supplier. Itech have a series of steel rebar bender machine,like CNC 16mm Stirrup Bending machine,CNC 20mm stirrup bar bending machine , 14mm stirrup wire bending machine and bar shape machine ,automatic rebar pile cage welding machine,cnc automatic pile cage making machine and many kinds of rebar machine. To solve the gap on the stirrups ,Itech stirrup bending machine adopt advanced anti twist feeding system to avoid twist of steel, make stirrup more quick and standard.Shape and bend stirrups effortlessly with our cutting-edge bending machine.

What to Expect at the Concrete Show São Paulo 2025

The Concrete Show São Paulo 2025 fair will host over 450 national and international brands, including 60 newcomers, showcasing their latest products and services across a sprawling 32,000 m² exhibition space. With more than 25,000 visitors from Latin America expected to attend, this event is a prime opportunity for industry professionals to engage with cutting-edge solutions and establish valuable connections.

Highlights of the Event

Innovative Exhibits: Discover the latest advancements in building materials, concrete mixing technology, and sustainable construction technologies.

Technical Seminars: Gain insights from industry leaders through more than 50 hours of exclusive content, including seminars and workshops focused on innovation and sustainability.

Networking Opportunities: Connect with professionals from over 30 countries, fostering partnerships and discussing critical issues for sustainable development in the construction sector.

Who Should Attend?

The Concrete Show São Paulo 2025 is tailored for a highly qualified audience, including entrepreneurs, professionals, executives, students, and researchers in the construction industry. Whether you are looking for solutions, technical content, or business relationships, this event offers a comprehensive experience for all attendees.

Why Visit the Concrete Show São Paulo 2025?

Stay Updated: Keep abreast of the latest trends and technologies in concrete and construction, reinforcement rebar processing machines.

Business Development: Establish business contacts and partnerships with leading national and international companies, like rebar cut and bend equipment supplier Itech.

Exclusive Attractions: Participate in unique attractions and activities that enhance your understanding of the industry.

The Venue: São Paulo Expo Exhibition & Convention Center

Located at Rodovia dos Imigrantes, Km 1.5, São Paulo, Brazil, the São Paulo Expo Exhibition & Convention Center is a modern facility offering state-of-the-art amenities. Easily accessible by various means of transportation, it provides a strategic location for both local and international visitors.

Event Organizers

The Concrete Show São Paulo 2025,With a strong presence in Latin America, Informa Markets is committed to supporting the regional construction industry and facilitating its growth through events like the Concrete Show.

Conclusion: Join the Concrete Show São Paulo 2025

Don’t miss the opportunity to be part of the Concrete Show São Paulo 2025 fair, where innovation meets opportunity. Whether you’re a seasoned professional or a newcomer to the construction industry, this event is your gateway to the future of concrete technology. Visit Concrete Show for more information and to register for this landmark event.

Discover the Concrete Show São Paulo 2025: A Premier Event for rebar processing machine Construction Industry Professionals

Prepare for three days of intensive learning and networking by marking your calendar for August 19-21, 2025. Share this article with colleagues and peers to ensure they don’t miss out on the Concrete Show São Paulo 2025, a pivotal event in the construction industry’s calendar.

Itech is professional steel wire/bar processing machinery China supplier,stirrup bending machine price , steel rebar bending machine,foundation pile cage making machine,,steel wire straightener,wire straightening and cutting machine, wire mesh welding machine,rebar shear line,rebar sawing&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.

Troubleshooting the Electrical Anti-Twist Automatic Stirrup Bender: Addressing the Feeding Servo EOOC Alarm

Troubleshooting the Electrical Anti-Twist Automatic Stirrup Bender: Addressing the Feeding Servo EOOC Alarm

The electrical anti-twist automatic stirrup bender is a crucial tool that meets demands by shaping steel bars into various forms used in construction site,reinforcement steel cut and bend factory, concrete precast factory. However, like any sophisticated machinery, it can encounter issues that require troubleshooting. One common problem operators face is the feeding servo EOOC alarm. This article delves into the causes of this alarm and provides practical solutions to ensure your stirrup bender operates smoothly.

itech Best selling CNC high quality automatic stirrup bending machine / CNC stirrup bender machine widely use in reinforcement steel wire bar cut and bend factory. Itech as professional reinforcing steel machine supplier. Itech have a series of steel rebar bender machine,like CNC 16mm Stirrup Bending machine,CNC 20mm stirrup bar bending machine , 14mm stirrup wire bending machine and bar shape machine ,automatic rebar pile cage welding machine,cnc automatic pile cage making machine and many kinds of rebar machine. To solve the gap on the stirrups ,Itech stirrup bending machine adopt advanced anti twist feeding system to avoid twist of steel, make stirrup more quick and standard.Shape and bend stirrups effortlessly with our cutting-edge bending machine.

Understanding the Feeding Servo EOOC Alarm

The feeding servo EOOC alarm is a specific error message that indicates an issue with the rebar stirrup bender servo motor responsible for feeding the material into the stirrup wire bender. This alarm can halt operations, leading to downtime and potential delays in production. Understanding the root causes of this alarm is the first step toward resolving it.

Common Causes of the EOOC Alarm

Overload Conditions: The servo motor may be under excessive load, causing it to trigger the EOOC alarm. This can happen if the material being fed is too thick or if there is a blockage in the feed path.

Electrical Issues: Faulty wiring or connections can lead to inconsistent power supply, causing the servo motor to malfunction and trigger the alarm.

Mechanical Blockages: Debris or misaligned components within the feeding mechanism can obstruct the smooth operation of the servo motor.

Software Glitches: Outdated or corrupted software controlling the servo motor can also result in the EOOC alarm.

Troubleshooting Steps

To address the feeding servo EOOC alarm, follow these steps:

- Inspect the Material and Feed Path

Check Material Specifications: Ensure that the material being fed into the stirrup bender is within the machine’s specified limits. Remove any material that appears too thick or irregular.

Clear Blockages: Inspect the feed path for any obstructions. Remove debris and ensure all components are aligned correctly.

- Examine Electrical Connections

Check Wiring: Inspect the wiring and connections to the servo motor. Look for loose or damaged wires and rectify any issues found.

Test Power Supply: Ensure that the power supply to the servo motor is stable and within the required voltage range.

- Update Software

Check for Updates: Ensure that the software controlling the servo motor is up-to-date. Manufacturers often release updates to fix known bugs and improve performance.

Reinstall Software: If the software appears corrupted, consider reinstalling it to restore normal operation.

- Monitor Load Conditions

Reduce Load: If the servo motor is overloaded, reduce the load by adjusting the material feed rate or using lighter materials.

Use Proper Lubrication: Ensure that all moving parts are properly lubricated to reduce friction and ease the load on the servo motor.

Troubleshooting the Electrical Anti-Twist Automatic Stirrup Bender: Addressing the

feeding Servo EOOC Alarm Conclusion

By understanding and addressing the common causes of the feeding servo EOOC alarm, operators can minimize downtime and ensure their electrical anti-twist automatic stirrup bender operates efficiently. Regular maintenance and timely software updates are crucial in preventing such alarms. For more detailed guidance, consider consulting the machine’s service manual or reaching out to itech for support.Incorporating these troubleshooting steps will not only resolve current issues but also enhance the longevity and reliability of your stirrup bender.

Remember, proactive maintenance and timely interventions are key to maintaining optimal machine performance. Share this article with colleagues who might benefit from these insights, and explore related topics to deepen your understanding of machinery troubleshooting.

Itech is professional steel wire/bar processing machinery China supplier,stirrup bending machine price , steel rebar bending machine,foundation pile cage making machine,,steel wire straightener,wire straightening and cutting machine, wire mesh welding machine,rebar shear line,rebar sawing&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.

For further information and to explore a wide range of automatic pile cage machines, visit leading suppliers itech. Embrace the future of construction technology today!

rebar double bender

rebar double bender

Concrete Show South East Asia - itech rebar cut and bend machine China manufacture & supplier

Concrete Show South East Asia - itech rebar cut and bend machine China manufacture & supplier concrete show south america

concrete show south america rebar bender

rebar bender