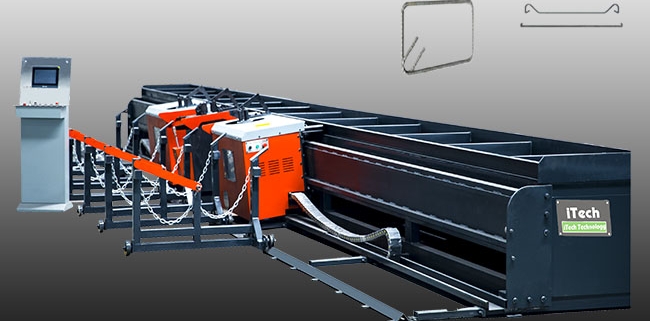

reinforcing steel rebar double bender machine in cut and bend factory

reinforcing steel rebar double bender machine in cut and bend factory

rebar double bender machine in cut and bend factory is important for process straight bar. Compared with automatic stirrup bender, rebar double bender is for bar , stirrup bending machine is for steel coil. One crucial component that enhances these aspects in cut and bend factories is the rebar double bender machine. This article explores the significance of these machines, their functionality, and their impact on the industry.

Understanding Rebar Double Bending Machines

Rebar double bender machines are essential tools in steel fabrication cut and bend factories, designed to bend reinforcement bars (rebars) with precision and speed. These machines are equipped with dual bending heads, allowing them to bend rebars in multiple directions simultaneously. This capability significantly reduces processing time and increases productivity, making them indispensable in large-scale construction projects.

itech Best selling CNC high quality automatic stirrup bending machine / CNC stirrup bender machine widely use in reinforcement steel wire bar cut and bend factory. Itech as professional reinforcing steel machine supplier. Itech have a series of steel rebar bender machine,like CNC 16mm Stirrup Bending machine,CNC 20mm stirrup bar bending machine , 14mm stirrup wire bending machine and bar shape machine ,automatic rebar pile cage welding machine,cnc automatic pile cage making machine and many kinds of rebar machine. To solve the gap on the stirrups ,Itech stirrup bending machine adopt advanced anti twist feeding system to avoid twist of steel, make stirrup more quick and standard.Shape and bend stirrups effortlessly with our cutting-edge bending machine.

Rebar bender Key Features and Benefits

Rebar double bender machines boast several features that make them stand out:

Dual Bending Heads: These machines can bend rebars in two directions at once, enhancing efficiency and reducing labor costs.

Automated Processes: The automation of bending processes ensures accuracy and consistency, minimizing errors and waste.

Versatility: Capable of handling various rebar diameters, these machines cater to diverse construction needs.

Cost-Effectiveness: By reducing manual labor and increasing speed, these machines contribute to significant cost savings.

reinforcing steel rebar double bender machine in cut and bend factory

Cutting and bending factories utilize rebar double bender machines to streamline operations. These factories are equipped with advanced machinery that automates the cutting and bending of steel bars, optimizing the steel fabrication process. The integration of rebar double bender machines in these factories ensures that rebars are processed efficiently, meeting the specific requirements of construction projects.

According to itech, a leading company in rebar fabrication equipment, their range of cutting and bending machines includes automatic double bending machines designed for reinforcement processing. These machines are engineered to handle various tasks, from producing stirrups to shaping wires for the construction industry.

Technological Advancements

The evolution of rebar double bender machines is marked by technological advancements. For instance, Itech offers machines equipped with electric servo motors and hydraulic systems, providing powerful and precise bending capabilities. These machines feature network remote assistance, allowing for seamless integration and monitoring of operations.

Moreover, the rebar shear line double bender, as described by Itech, combines cutting and bending processes in one integrated system. This innovation not only boosts efficiency but also ensures that rebars are cut and bent with high precision, catering to the growing demands of modern construction projects.

Conclusion

Rebar double bender machines play a pivotal role in cut and bend factories, transforming the way rebars are processed and fabricated. Their ability to enhance efficiency, reduce costs, and ensure precision makes them invaluable assets in the construction industry. As technology continues to advance, these machines will undoubtedly evolve, offering even greater benefits to factories and construction projects worldwide.

For those interested in exploring the capabilities of rebar double bender machines, consider visiting industry-leading manufacturers like Itech to discover the latest innovations and solutions tailored to your construction needs.

Itech is professional steel wire/bar processing machinery China supplier,stirrup bending machine price , steel rebar bending machine,foundation pile cage making machine,,steel wire straightener,wire straightening and cutting machine, wire mesh welding machine,rebar shear line,rebar sawing&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.

For further information and to explore a wide range of automatic pile cage machines, visit leading suppliers itech. Embrace the future of construction technology today!

reinforcing steel rebar double bender machine in cut and bend factory

rebar double bender machine in cut and bend factory is important for process straight bar. Compared with automatic stirrup bender, rebar double bender is for bar , stirrup bending machine is for steel coil. One crucial component that enhances these aspects in cut and bend factories is the rebar double bender machine. This article explores the significance of these machines, their functionality, and their impact on the industry.

Understanding Rebar Double Bending Machines

Rebar double bender machines are essential tools in steel fabrication cut and bend factories, designed to bend reinforcement bars (rebars) with precision and speed. These machines are equipped with dual bending heads, allowing them to bend rebars in multiple directions simultaneously. This capability significantly reduces processing time and increases productivity, making them indispensable in large-scale construction projects.

itech Best selling CNC high quality automatic stirrup bending machine / CNC stirrup bender machine widely use in reinforcement steel wire bar cut and bend factory. Itech as professional reinforcing steel machine supplier. Itech have a series of steel rebar bender machine,like CNC 16mm Stirrup Bending machine,CNC 20mm stirrup bar bending machine , 14mm stirrup wire bending machine and bar shape machine ,automatic rebar pile cage welding machine,cnc automatic pile cage making machine and many kinds of rebar machine. To solve the gap on the stirrups ,Itech stirrup bending machine adopt advanced anti twist feeding system to avoid twist of steel, make stirrup more quick and standard.Shape and bend stirrups effortlessly with our cutting-edge bending machine.

www.itechbendingmachine.com

whatsapp+8615210021224

Automatic Rebar Stirrup Bender CNC Steel Bar Stirrup Bending Machine Automatic Steel Bending Hoop Machine آلة ثني الفولاذ التلقائية Automatische buigmachine voor stalen staven Mesin ring bending baja otomatis 自動スチールベンディングフープマシン 자동 스틸 바 벤딩 머신 Автомат ган гулзайлтын машин Автоматическая машина для гибки стальных пялец Dobladora automática de aro de acero Máy uốn thép tự động #construction #Machinetools #engineering #technology #constructionmachinery #Heavymachinery #rebarbender #stirrupbender #stirrupbendingmachine #cncrebarstirrupbener #steelbarbender #steelbarstirrpbender #hoopbender #hoopbendingmachine #rebarmachine #rebarbending #rebarhoopbender #steelbarhoopbendingmachine

#stirrupbender,#stirrupbendingmachine,#rebarbender,#rebarcutter,#barbendingmachine,#ironformingmachine,

#pilecagemachine,#wiremeshweldingmachine,#meshmachine,#doublebender,#rebarshearline,

#straighteningmachine,#straighteningandcuttingmachine,

#wirestraigtener,#rebarthreading #rebar #steel #staal #telaviv #moscow #texas #constructionlife #iron #mills #stirrups #best #buildings #industrialdesign #wire nb #machinery #steelwire #dubai #israel #bendingmachine #spain #germany #france #Netherlands #holland #belgium #ireland #england #unitedkingdom

Itech is professional steel wire/bar processing machinery China supplier,stirrup bending machine price , steel rebar bending machine,foundation pile cage making machine,,steel wire straightener,wire straightening and cutting machine, wire mesh welding machine,rebar shear line,rebar sawing&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.

Revolutionizing Construction: The Role of Automatic Pile Cage Machine in Foundation drilling Equipment

Revolutionizing Construction: The Role of Automatic Pile Cage Machine in Foundation drilling Equipment

automatic pile cage machine—a game-changer in foundation drilling equipment. Used Automatic pile cage machine mostly in foundation drilling company,reinforcement cut and bend factory, building materials factory. This innovative technology is transforming how pile cages are manufactured, offering significant advantages in terms of speed, accuracy, and cost-effectiveness. Whether you’re a construction professional or an industry enthusiast, understanding the capabilities and benefits of these machines can provide a competitive edge.

itech Best selling CNC high quality automatic stirrup bending machine / CNC stirrup bender machine widely use in reinforcement steel wire bar cut and bend factory. Itech as professional reinforcing steel machine supplier. Itech have a series of steel rebar bender machine,like CNC 16mm Stirrup Bending machine,CNC 20mm stirrup bar bending machine , 14mm stirrup wire bending machine and bar shape machine ,automatic rebar pile cage welding machine,cnc automatic pile cage making machine and many kinds of rebar machine. To solve the gap on the stirrups ,Itech stirrup bending machine adopt advanced anti twist feeding system to avoid twist of steel, make stirrup more quick and standard.Shape and bend stirrups effortlessly with our cutting-edge bending machine.

What is an Automatic Pile Cage Machine?

automatic pile cage machine is a sophisticated piece of equipment used to fabricate reinforcement cages for concrete piles. These machines automate the welding and assembly process, producing high-quality cages with minimal labor. The integration of CNC technology allows for precise control over the design and dimensions of the cages, catering to various construction needs.

Key Features and Benefits

Enhanced Productivity: Automatic pile cage machines significantly reduce the time and labor required to produce reinforcement cages. With features like programmable settings and automated welding, these machines can operate continuously, increasing output and efficiency.

Precision and Consistency: The use of CNC technology ensures that each cage is manufactured to exact specifications. This precision minimizes errors and waste, leading to more consistent quality in construction projects.

Cost-Effectiveness: By reducing the need for manual labor and increasing production speed, automatic pile cage machines lower overall project costs. The initial investment in these machines is quickly offset by savings in labor and material costs.

Versatility: These machines can produce a wide range of cage sizes and shapes, accommodating different construction requirements. Whether for cylindrical, square, or custom-shaped cages, automatic pile cage machines offer unmatched flexibility.

Automatic Pile Cage Machine in Foundation drilling Equipment Industry Insights and Trends

According to top suppliers on platforms like itech, the demand for automatic pile cage machines is on the rise. itech emphasize the machines’ ability to handle different wire diameters and cage lengths, catering to diverse project needs.

Leading Suppliers and Products

Itech rebar cage machine Series: series offers a range of models with varying capacities, from the compact300 to the robust 2500. These machines are celebrated for their high productivity and user-friendly controls.

Itech cage Pile Fab: This machine features smart assistance technology, enabling efficient fabrication with minimal labor. Its advanced software and motorized welding robot ensure high-quality welds and easy operation.

How to Choose the Right Machine

When selecting an automatic pile cage machine, consider factors such as:

Project Requirements: Determine the cage sizes and shapes needed for your projects.

Budget: Evaluate the cost versus the expected return on investment.

Supplier Reputation: Choose reputable suppliers with positive reviews and reliable after-sales support.

Conclusion

Automatic pile cage machines are revolutionizing the construction industry by enhancing efficiency, precision, and cost-effectiveness. As more companies recognize the benefits of these machines, their adoption is set to increase, driving innovation and quality in construction projects. For those looking to stay ahead in the competitive construction landscape, investing in an automatic pile cage machine could be a strategic move. Explore the latest models and suppliers to find the perfect fit for your needs and elevate your construction capabilities.

Itech is professional steel wire/bar processing machinery China supplier,stirrup bending machine price , steel rebar bending machine,foundation pile cage making machine,,steel wire straightener,wire straightening and cutting machine, wire mesh welding machine,rebar shear line,rebar sawing&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.

For further information and to explore a wide range of automatic pile cage machines, visit leading suppliers itech. Embrace the future of construction technology today!

Mastering Automatic Stirrup Bender Machines Maintenance and Troubleshooting : rebar feeding servo alarm

Mastering Automatic Stirrup Bender Machines Maintenance and Troubleshooting : rebar feeding servo alarm

In the developping world of construction, automatic rebar machine is one trend. The automatic rebar stirrup bender machine, a vital piece of equipment in reinforcement steel cut and bend factory,precast factory and construction company, offers a high efficiency rebar bending and cuting process,improve production capacity. However, like all machinery, it requires regular maintenance and troubleshooting to function optimally. This article delves into the essential aspects of maintaining and troubleshooting automatic rebar stirrup bender machines, ensuring they continue to perform flawlessly.

itech Best selling CNC high quality automatic stirrup bending machine / CNC stirrup bender machine widely use in reinforcement steel wire bar cut and bend factory. Itech as professional reinforcing steel machine supplier. Itech have a series of steel rebar bender machine,like CNC 16mm Stirrup Bending machine,CNC 20mm stirrup bar bending machine , 14mm stirrup wire bending machine and bar shape machine ,automatic rebar pile cage welding machine,cnc automatic pile cage making machine and many kinds of rebar machine. To solve the gap on the stirrups ,Itech stirrup bending machine adopt advanced anti twist feeding system to avoid twist of steel, make stirrup more quick and standard.Shape and bend stirrups effortlessly with our cutting-edge bending machine.

Understanding the Automatic reinforcing steel wire Stirrup Bending Machine

Automatic stirrup bending machines made of by rebar wire feeding servo, rebar bending servo and cutting system. The all system use anti twist system, so avoid wire twist when wire feeding. After rebar feeding, then rebar bender machine finish bending process according to the shapes on touch screen. Rebar bending machine cutting by fix balde and movable blades. Servo system is the most important parts for rebar bending machine. Automatic stirrup bender servo Maintenance and Troubleshooting is important job for maintenance people. Regular Maintenance Practices

Common Troubleshooting Techniques

Despite regular maintenance, issues may still arise. Here are some common problems and their solutions:

Machine Won’t Start:

Possible Causes: Power failure, loose power line, or faulty power button.

Solutions: Check the power supply, tighten any loose connections, and replace the power button if necessary.

Inaccurate Bending Angles:

Possible Causes: Incorrect parameter settings or misaligned clamping device.

Solutions: Reassess and adjust the parameters, ensuring the clamping device is correctly aligned.

Unstable Operation:

Possible Causes: Lack of maintenance, excessive friction, or loose protective covers.

Solutions: Conduct regular maintenance, lubricate moving parts, and secure all protective covers.

Motor Reversion:

Possible Causes: Jammed bending arm or loose angle adjuster clips.

Solutions: Adjust the bending arm and secure the adjuster clips.

Mastering Automatic Stirrup Bender Machines Maintenance and Troubleshooting : rebar feeding servo alarm error 731

Bending servo 731 alarm happend when the bending servo wire remove and wire break. So when have alarm 731, first step is check the wire connection. After connect well wire cables, need operate on the servo panel.

- Press set

- Press mode

- Press up arrow until find D

- Press set

- Press right arrow

- Press up arrow and change 0 to 2

- Press set

- Press up arrow,make 0 to 1

- Press set 5 seconds

The automatic rebar stirrup bender machine is an indispensable tool in construction, offering unmatched efficiency and precision. By adhering to regular maintenance schedules and employing effective troubleshooting techniques, you can ensure its longevity and optimal performance. For further insights, consider exploring expert resources and engaging with industry webinars to stay updated on best practices. Remember, a well-maintained machine is not only a cost-effective investment but also a cornerstone of successful construction projects.

Call to Action: For more detailed maintenance tips and troubleshooting guides, subscribe to industry webinars or consult with itech rebar machinery experts. Share this article with your colleagues to promote best practices in rebar stirrup bender machine maintenance.

Itech is professional steel wire/bar processing machinery China supplier,stirrup bending machine price , steel rebar bending machine,foundation pile cage making machine,,steel wire straightener,wire straightening and cutting machine, wire mesh welding machine,rebar shear line,rebar sawing&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.

Itech Reliable Pile Cage Welding Machine Supplier at Factory Price

Itech Reliable Pile Cage Welding Machine Supplier at Factory Price

In the construction industry steel cut and bend factory and pile foundation company , Reliable Pile Cage Welding Machine is a vital piece of equipment that ensures the integrity and strength of concrete piles. If you’re in the market for a pile cage, finding a reliable rebar pile cage making machine supplier offering factory prices is crucial. This guide will help you navigate the process, ensuring you make an informed decision.

itech Best selling CNC high quality automatic stirrup bending machine / CNC stirrup bender machine widely use in reinforcement steel wire bar cut and bend factory. Itech as professional reinforcing steel machine supplier. Itech have a series of steel rebar bender machine,like CNC 16mm Stirrup Bending machine,CNC 20mm stirrup bar bending machine , 14mm stirrup wire bending machine and bar shape machine ,automatic rebar pile cage welding machine,cnc automatic pile cage making machine and many kinds of rebar machine. To solve the gap on the stirrups ,Itech stirrup bending machine adopt advanced anti twist feeding system to avoid twist of steel, make stirrup more quick and standard.Shape and bend stirrups effortlessly with our cutting-edge bending machine.

Understanding Pile Cage Welding Machines

Automatic Pile cage welding machines are used to weld steel reinforcement cages that form the core of concrete piles. These machines are essential in the construction of foundations for buildings, bridges, and other infrastructure projects. They offer automation, precision, and speed, significantly reducing labor costs and time.

Key Features to Consider:

Automation Level: Automatic and CNC-controlled machines offer higher precision and efficiency.

Control System: People can input the cage spiral space, the disk rotate speed, the moving speed on touch screen. Itech cage machine are available for heavy-duty operations.it is easy to operate and handle.

Cage support frame: when steel rebar cage machine running, it need strong cage support frame to support.

Capacity and Size: Ensure the machine can handle the size and type of pile cages you need to produce, with options ranging from small to large diameters.

Durability and Warranty: Consider machines made from high-quality materials that come with a warranty for peace of mind.

Itech Reliable Pile Cage Welding Machine Supplier at Factory Price

Cost Efficiency: Direct purchase from manufacturers often results in lower prices.

Customization: Manufacturers can offer tailored solutions to meet specific project needs.

Direct Support: Access to technical support and service directly from the itech rebar machine manufacturer.

Making the Right Choice

When selecting a automatic pile cage welding machine supplier, consider the following steps to ensure you make the best choice:

Research and Compare: supplier is professional or not?can give suitable suggestion.

customer Reviews: Customer reviews and testimonials can provide insights into the supplier’s reliability and product performance.

Request Quotes: Contact itech rebar processing machine suppliers for detailed quotes and compare them to assess the best value for money.

Evaluate After-Sales Support: itech can offer comprehensive after-sales support, including warranty and technical assistance.

Conclusion

itech as reliable pile cage welding machine supplier at factory price requires careful consideration of various factors, including automation, capacity, and supplier reputation. By choosing itech as rebar machine supplier, you can ensure the efficiency and quality of your construction projects, ultimately leading to better outcomes and cost savings. Take action now by reaching out to reputable itech and securing the best equipment for your needs.

Itech is professional steel wire/bar processing machinery China supplier,stirrup bending machine price , steel rebar bending machine,foundation pile cage making machine,,steel wire straightener,wire straightening and cutting machine, wire mesh welding machine,rebar shear line,rebar sawing&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.

How Itech Cut and Bend Equipment automatic Stirrup Bender Successfully Installed in Iraq

How Itech Cut and Bend Equipment automatic Stirrup Bender Successfully Installed in Iraq

The installation of Itech’s cut and bend equipment automatic stirrup bender, in Iraq marks a significant milestone for the region’s infrastructure development. This automatic stirrup bending machinery not only enhances productivity but also ensures the quality and safety of construction projects,cut and bend factory,concrete precast factory projects. In this article, we will explore the successful installation of Itech automatic stirrup bender in Iraq, highlighting its features, benefits, and impact on the local construction sector.we’ll explore the benefits of this innovative equipment and its impact on the construction landscape in Iraq.

itech Best selling CNC high quality automatic stirrup bending machine / CNC stirrup bender machine widely use in reinforcement steel wire bar cut and bend factory. Itech as professional reinforcing steel machine supplier. Itech have a series of steel rebar bender machine,like CNC 16mm Stirrup Bending machine,CNC 20mm stirrup bar bending machine , 14mm stirrup wire bending machine and bar shape machine ,automatic rebar pile cage welding machine,cnc automatic pile cage making machine and many kinds of rebar machine. To solve the gap on the stirrups ,Itech stirrup bending machine adopt advanced anti twist feeding system to avoid twist of steel, make stirrup more quick and standard.Shape and bend stirrups effortlessly with our cutting-edge bending machine.

The construction industry in Iraq has witnessed a significant technological advancement with the successful installation of the Itech cut and bend equipment, specifically the automatic stirrup bender.The Itech automatic stirrup bender is renowned for its advanced features, including an anti-twist system, electric servo motors, and a maximum pulling speed of 120 meters per minute.

Key Features of the Itech Automatic Stirrup Benders

Anti-Twist System rebar stirrup bender: Ensures precision by preventing twists in the steel during the bending process.

Electric Servo Motors stirrup bending machine: Enhance the machine’s efficiency and accuracy.

High Pulling Speed rebar bender : Capable of pulling wire at 120 meters per minute, significantly boosting productivity.

Network Remote Assistance stirrup bending machines: Offers remote troubleshooting and support, ensuring minimal downtime.

Installation Success in Iraq

The installation of the Itech reinforcing steel wire stirrup bender in Iraq marks a pivotal moment for the country’s construction industry. Itech rebar machine ability to produce 1,800 to 2,000 stirrups per hour equates to replacing at least ten manual workers, significantly reducing labor costs and time.

Benefits of the Installation reinforcement steel wire bender

Increased Efficiency: The automatic stirrup bender streamlines the production process, allowing for faster project completion.

Cost-Effective: By reducing the need for manual labor, construction companies can save on labor costs.

Enhanced Precision: The anti-twist system and servo motors ensure that each stirrup is produced with high accuracy, meeting stringent quality standards.

Scalability: The machine’s high output capacity allows construction firms to scale operations easily to meet increasing demands.

The Impact on Iraq’s Construction Industry

The introduction of advanced machinery like the Itech automatic stirrup bender is a game-changer for Iraq’s construction sector. It not only boosts productivity but also sets a new standard for quality and efficiency. The machine’s installation is expected to encourage more construction companies in Iraq to adopt similar technologies, fostering a culture of innovation and modernization.

Conclusion

The successful installation of the Itech cut and bend equipment, specifically the automatic stirrup bender, in Iraq is a testament to the country’s commitment to advancing its construction industry. This cutting-edge technology is poised to transform the way construction projects are executed, offering unprecedented efficiency and precision. As the industry continues to evolve, embracing such innovations will be crucial for maintaining competitiveness and meeting the growing demands of modern construction.

For more information on the Itech automatic stirrup bender and its features, visit Itech Technology Co., Ltd. Explore how this revolutionary equipment can benefit your construction projects and stay ahead in the industry.

Itech is professional steel wire/bar processing machinery China supplier,stirrup bending machine price , steel rebar bending machine,foundation pile cage making machine,,steel wire straightener,wire straightening and cutting machine, wire mesh welding machine,rebar shear line,rebar sawing&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.

Maintaining and Troubleshooting Automatic Stirrup Bending Machines

Maintaining and Troubleshooting Automatic Stirrup Bending Machines: Cutting Servo Alarm with Dual Line Operations

Automatic stirrup bending machines are vital in the construction building materials industry, precast concrete,reinforcement steel prefabricate cut and bend factory. Rebar bending machine is for shaping steel bars into stirrups. However, like any sophisticated machinery, they require regular maintenance and troubleshooting to operate optimally. In this article, we delve into the maintenance practices and troubleshooting techniques for automatic stirrup bending machines, particularly focusing on addressing the cutting servo alarm when working with two lines.

itech Best selling CNC high quality automatic stirrup bending machine / CNC stirrup bender machine widely use in reinforcement steel wire bar cut and bend factory. Itech as professional reinforcing steel machine supplier. Itech have a series of steel rebar bender machine,like CNC 16mm Stirrup Bending machine,CNC 20mm stirrup bar bending machine , 14mm stirrup wire bending machine and bar shape machine ,automatic rebar pile cage welding machine,cnc automatic pile cage making machine and many kinds of rebar machine. To solve the gap on the stirrups ,Itech stirrup bending machine adopt advanced anti twist feeding system to avoid twist of steel, make stirrup more quick and standard.Shape and bend stirrups effortlessly with our cutting-edge bending machine.

Understanding the Automatic Stirrup Bender Machine

Automatic stirrup bending machines are designed to transform long steel rods into various shapes, primarily used in reinforcing concrete structures. These machines are equipped with advanced features like cutting servos, which enhance their precision and speed. However, when operating with two lines, users may encounter a cutting servo alarm, indicating a malfunction that needs immediate attention.

Regular Maintenance Practices

To ensure the longevity and optimal performance of your automatic reinforcement steel wire stirrup bending machine, adhere to the following maintenance practices:

Routine Cleaning: After each use, clean the machine to remove debris, dust, and residue. This prevents buildup that could impair performance.

Lubrication: Regularly lubricate all moving parts as per the itech bending machine’s guidelines to reduce friction and wear.

Component Inspection: Frequently inspect the bending machine components, including wire bending machine tools, blades, and guides, for signs of wear and tear. Replace or repair damaged parts promptly.

Alignment Checks: Ensure the machine components are properly aligned to maintain bending accuracy. Misalignment can lead to faulty bends and compromise output quality.

Monitor Settings: Regularly monitor and adjust tension and pressure settings according to material and bending requirements. Incorrect settings can damage both the material and the machine.

Electrical Components: Ensure all electrical connections are secure and in good condition to avoid electrical issues.

Maintaining and Troubleshooting Automatic Stirrup Bending Machines: Cutting Servo Alarm with Dual Line Operations

When operating with two lines, encountering a cutting servo alarm can disrupt operations. Here are steps to troubleshoot and resolve this issue:

Check Servo Parameters: Ensure that the servo parameters are set correctly. Incorrect settings can cause communication errors and trigger alarms.

Inspect Communication Lines: Verify that the communication lines connecting the PLC to the servo are intact and functioning. Damaged or loose connections can lead to alarms.

Examine Terminal Resistors: If the last servo in the sequence has a terminal resistor, ensure it is correctly dialed. Incorrect resistor settings can cause malfunctions.

Review Axis Limits: Check if the axis limits are set appropriately. Exceeding these limits can trigger alarms. Adjust the limits or reset the reference points as needed.avoid the bender arm touch blade.adjust 0 position if happened this.

Emergency Stop Switch: Ensure that the emergency stop switch is released. A pressed switch can prevent the machine from operating correctly.

Inspect Feedback Signals: Check if there are feedback signals from the servo. Lack of feedback can indicate a wiring issue that needs addressing.

Check the cutting shaft and shaft cover, it should be connect well but no very tight,otherwise the cutting shaft will be block by the shaft cover. Especially when install cutting shaft and shaft cover, do not use hammer to hit directly. Hit to wood before shaft cover.

Conclusion

Maintaining and troubleshooting an automatic stirrup bending machine, especially when dealing with cutting servo alarms in dual line operations, requires meticulous attention to detail and adherence to best practices. By following regular maintenance routines and employing effective troubleshooting techniques, you can ensure your machine operates efficiently and reliably. For further assistance, consult the machine’s manual or reach out to professional technicians. Your proactive approach will not only extend the machine’s lifespan but also enhance productivity and safety in your operations.

For more insights and expert advice on maintaining bending machines, explore our resources or contact us for personalized support.

Itech is professional steel wire/bar processing machinery China supplier,stirrup bending machine price , steel rebar bending machine,foundation pile cage making machine,,steel wire straightener,wire straightening and cutting machine, wire mesh welding machine,rebar shear line,rebar sawing&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.

Maintaining and Troubleshooting Automatic Stirrup Bending Machines: Cutting Servo Alarm with Dual Line Operations

Automatic stirrup bending machines are vital in the construction building materials industry, precast concrete,reinforcement steel prefabricate cut and bend factory. Rebar bending machine is for shaping steel bars into stirrups. However, like any sophisticated machinery, they require regular maintenance and troubleshooting to operate optimally. In this article, we delve into the maintenance practices and troubleshooting techniques for automatic stirrup bending machines, particularly focusing on addressing the cutting servo alarm when working with two lines.

itech Best selling CNC high quality automatic stirrup bending machine / CNC stirrup bender machine widely use in reinforcement steel wire bar cut and bend factory. Itech as professional reinforcing steel machine supplier. Itech have a series of steel rebar bender machine,like CNC 16mm Stirrup Bending machine,CNC 20mm stirrup bar bending machine , 14mm stirrup wire bending machine and bar shape machine ,automatic rebar pile cage welding machine,cnc automatic pile cage making machine and many kinds of rebar machine. To solve the gap on the stirrups ,Itech stirrup bending machine adopt advanced anti twist feeding system to avoid twist of steel, make stirrup more quick and standard.Shape and bend stirrups effortlessly with our cutting-edge bending machine.

www.itechbendingmachine.com

whatsapp+8615210021224

Automatic Rebar Stirrup Bender CNC Steel Bar Stirrup Bending Machine Automatic Steel Bending Hoop Machine آلة ثني الفولاذ التلقائية Automatische buigmachine voor stalen staven Mesin ring bending baja otomatis 自動スチールベンディングフープマシン 자동 스틸 바 벤딩 머신 Автомат ган гулзайлтын машин Автоматическая машина для гибки стальных пялец Dobladora automática de aro de acero Máy uốn thép tự động #construction #Machinetools #engineering #technology #constructionmachinery #Heavymachinery #rebarbender #stirrupbender #stirrupbendingmachine #cncrebarstirrupbener #steelbarbender #steelbarstirrpbender #hoopbender #hoopbendingmachine #rebarmachine #rebarbending #rebarhoopbender #steelbarhoopbendingmachine

#stirrupbender,#stirrupbendingmachine,#rebarbender,#rebarcutter,#barbendingmachine,#ironformingmachine,

#pilecagemachine,#wiremeshweldingmachine,#meshmachine,#doublebender,#rebarshearline,

#straighteningmachine,#straighteningandcuttingmachine,

#wirestraigtener,#rebarthreading #rebar #steel #staal #telaviv #moscow #texas #constructionlife #iron #mills #stirrups #best #buildings #industrialdesign #wire nb #machinery #steelwire #dubai #israel #bendingmachine #spain #germany #france #Netherlands #holland #belgium #ireland #england #unitedkingdom

Itech is professional steel wire/bar processing machinery China supplier,stirrup bending machine price , steel rebar bending machine,foundation pile cage making machine,,steel wire straightener,wire straightening and cutting machine, wire mesh welding machine,rebar shear line,rebar sawing&threading line and related cnc plasma cutting machine, laser cutting machine can meet different customers’ requirement.

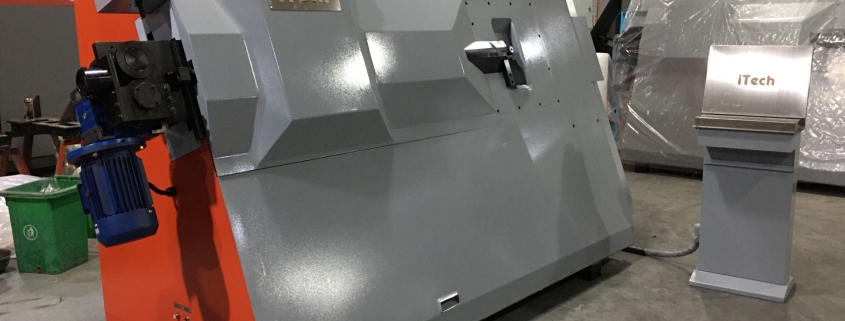

double bending machine

double bending machine pile cage machine

pile cage machine

rebar bend and cut factory

rebar bend and cut factory  rebar bender

rebar bender